Parachloronitrobenzene hydrogenation reduction catalyst capable of being magnetically recycled and preparation method

A technology of p-chloronitrobenzene and catalyst, which is applied in the preparation of amino compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as environmental hazards and harsh reaction conditions, and achieve adsorption and dispersion promotion, the availability of raw materials, the effect of changing the lattice structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

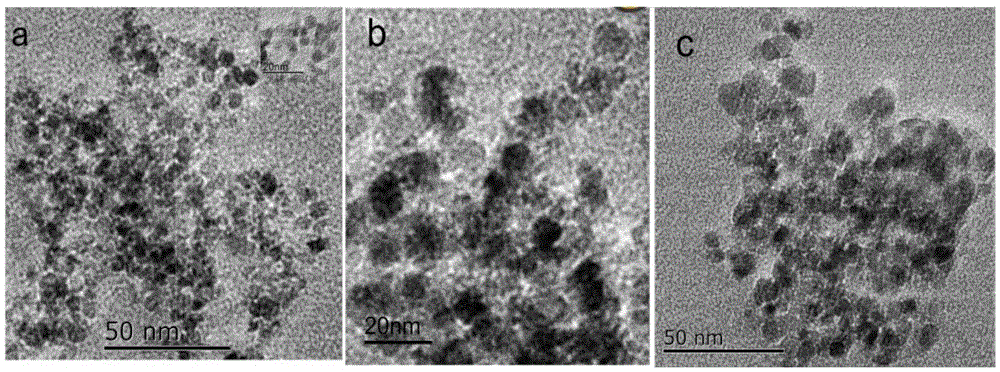

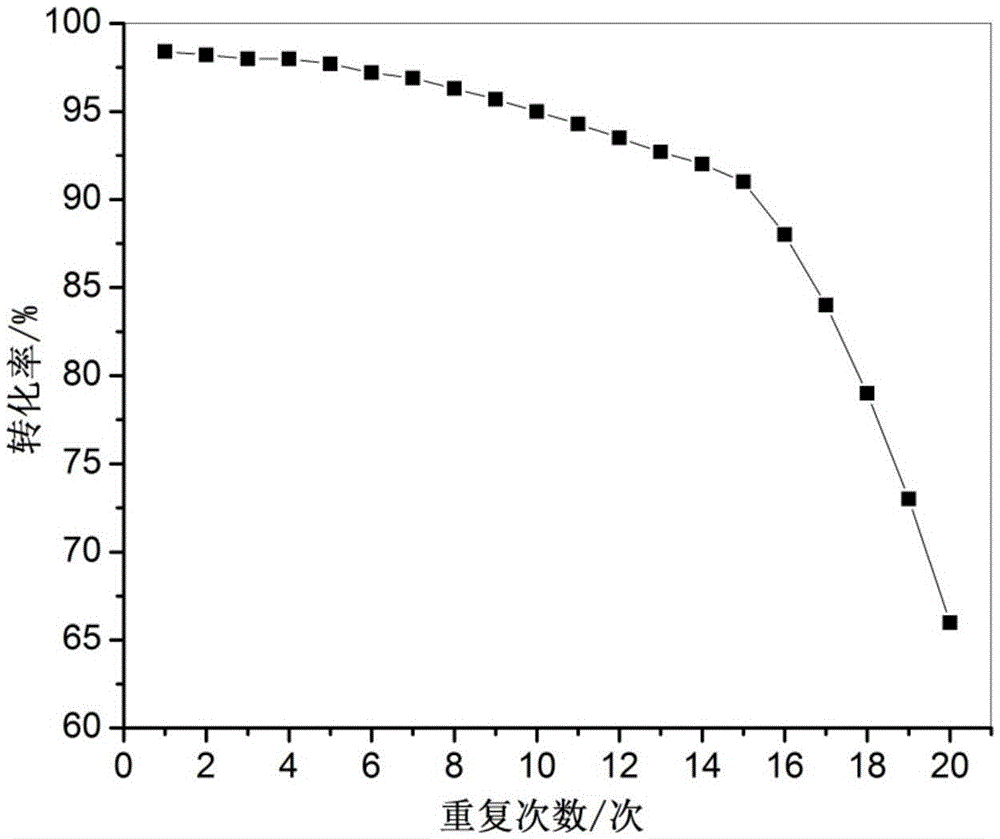

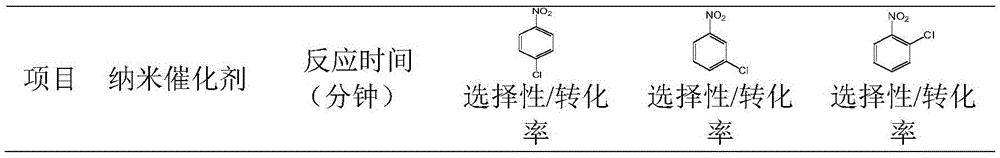

Image

Examples

Embodiment 1

[0030] Add 270ml of deionized water and 40.5g of ferric chloride into a 500ml three-neck flask and stir to form a homogeneous solution. Add 0.3M KO 2 Slowly add to the solution, stir vigorously, and pass through N 2 Protected, reacted at a temperature of 343K for 2h, and continued to stir for half an hour after the color of the system turned black and gas was no longer released. Stand still until all the black powder in the system sinks to the bottom of the bottle, suck out the upper liquid, first wash repeatedly with deionized water to maintain the pH value of the obtained product at about 7, then add 50ml of methanol washing solution for washing, and put it in a vacuum drying oven after washing Dry at room temperature for 12 hours to obtain magnetic nanoparticles.

[0031] Weigh 50 g of deionized water, add 5 mmol of cobalt sulfate, stir and dissolve for 5 min to obtain cobalt sulfate solution, add 0.01 mol of nano-magnetic particles prepared above, and pass N 2 Protected,...

Embodiment 2

[0034] Add 270ml of deionized water and 60g of ferric sulfate into a 500ml three-necked flask and stir to form a homogeneous solution. Add 0.3M KO 2 Slowly add to the solution, stir vigorously, and pass through N 2 Protected, reacted at a temperature of 343K for 2h, and continued to stir for half an hour after the color of the system turned black and gas was no longer released. Stand still until all the black powder in the system sinks to the bottom of the bottle, suck out the upper liquid, first wash repeatedly with deionized water to maintain the pH value of the obtained product at about 7, then add 50ml of methanol washing solution for washing, and put it in a vacuum drying oven after washing Dry at room temperature for 10 h to obtain magnetic nanoparticles.

[0035] Weigh 50g of deionized water, add 5mmol cobalt chloride, stir and dissolve for 5min to obtain a cobalt chloride solution, add 0.01mol of the above-prepared nano-magnetic particles, and pass N 2 Protected, ult...

Embodiment 3

[0038] Add 270ml of deionized water and 60g of ferric sulfate into a 500ml three-necked flask and stir to form a homogeneous solution. Add 0.2M KO 2 Slowly add to the solution, stir vigorously, and pass through N 2 Protected, reacted at a temperature of 343K for 2h, and continued to stir for half an hour after the color of the system turned black and gas was no longer released. Stand still until all the black powder in the system sinks to the bottom of the bottle, suck out the upper liquid, first wash repeatedly with deionized water to maintain the pH value of the obtained product at about 7, then add 50ml of methanol washing solution for washing, and put it in a vacuum drying oven after washing Dry at room temperature for 10 h to obtain magnetic nanoparticles.

[0039] Weigh 50g of deionized water, add 5mmol of cobalt nitrate, stir and dissolve for 5min to obtain a cobalt nitrate solution, add 0.01mol of the above-prepared nano-magnetic particles, and pass N 2 Protected, ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com