Three-dimensional graphene aerogel material for dye adsorption and preparation method thereof

A graphene aerogel, graphene technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as structure fixation, and achieve the effects of high porosity, fast adsorption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of 2-urea-4-[H]-pyrimidinone: Weigh 0.125g of 6-methylisocytosine into a three-necked flask, then add 1.008g of 1,6-hexamethylene diisocyanate, Under the protection of the atmosphere, react at 80°C for 12 hours, then precipitate with petroleum ether with a boiling point of 30-60, separate and dry to obtain 0.26 g of the product 2-urea-4-[H]-pyrimidinone.

[0026] 2) Reaction of 2-urea-4-[H]-pyrimidinone with graphene oxide: Weigh 0.26g of 2-urea-4-[H]-pyrimidinone into a three-necked flask, pour 30ml of anhydrous N, N-dimethylformamide; then add 0.13g of graphene oxide, and ultrasonically disperse the mixture for 30 minutes; add dibutyltin dilaurate in parts per thousand, and react at 80°C under the protection of an argon atmosphere After 6 hours, 0.3 g of the product 2-urea-4-[H]-pyrimidinone-modified graphene was obtained by suction filtration.

[0027] 3) Preparation of three-dimensional structure graphene: disperse 0.3g of 2-urea-4-[H]-pyrimidinone-m...

example 1

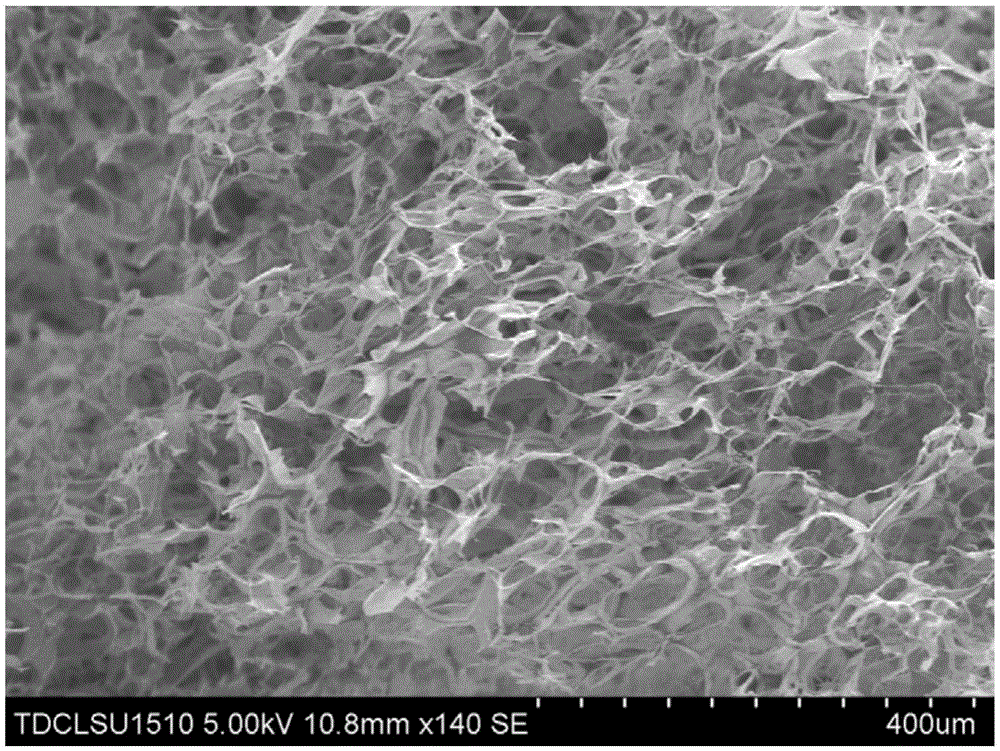

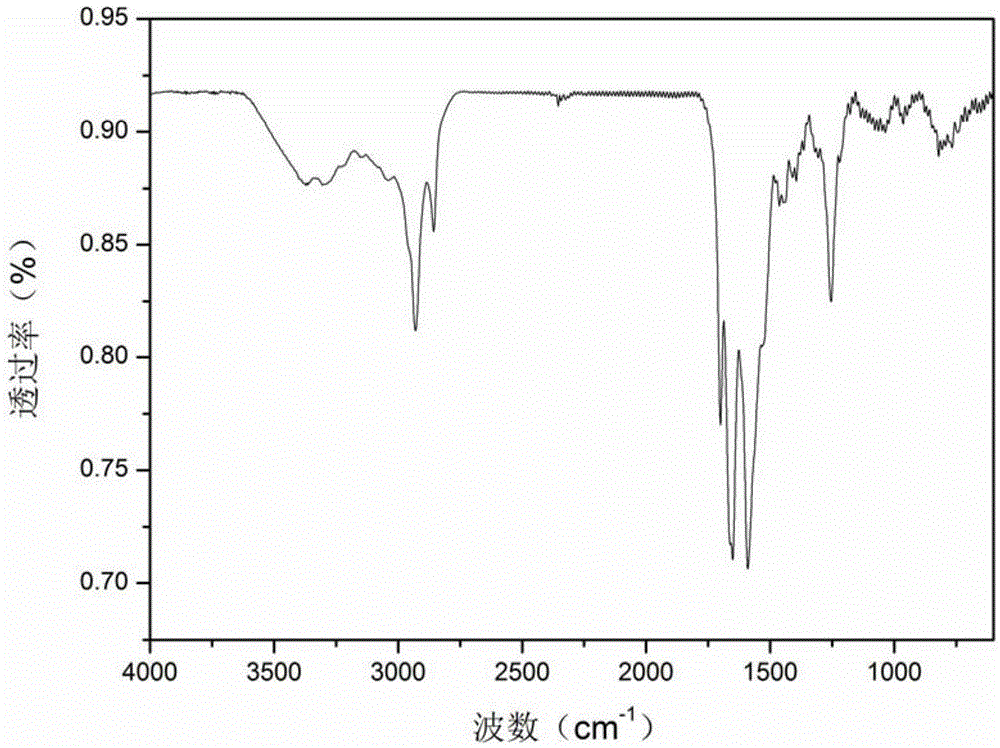

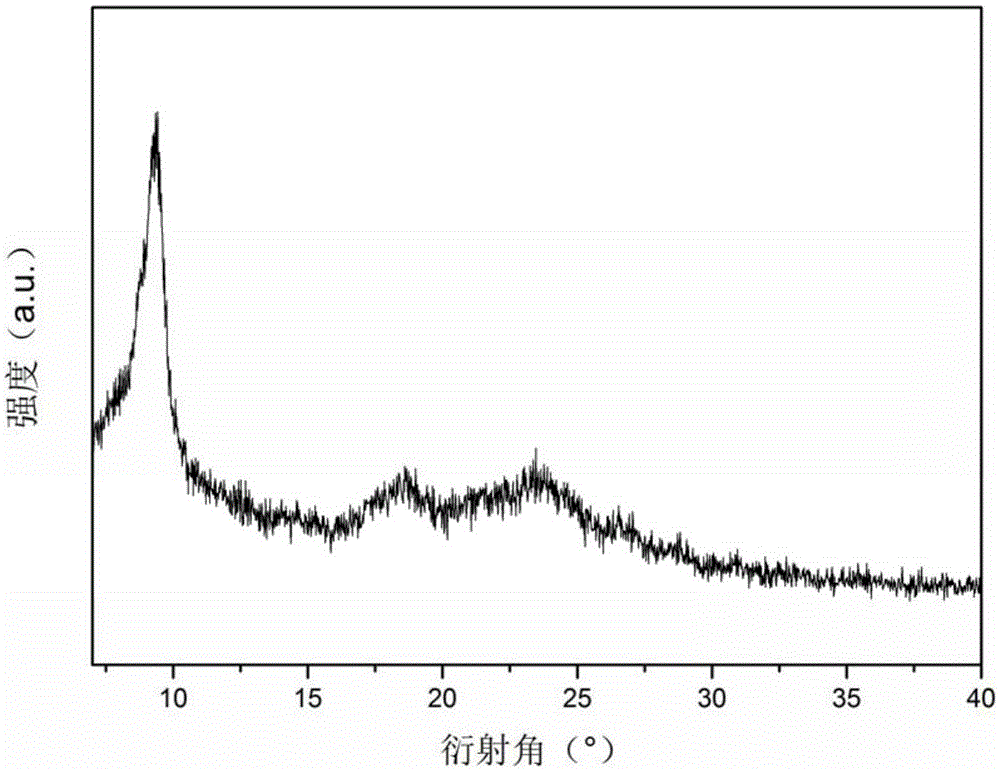

[0028] The scanning electron micrograph of the three-dimensional structure graphene material that example 1 obtains is as figure 1 As shown, the morphology presents a three-dimensional interpenetrating porous structure; a certain amount of sample is taken to test the Fourier transform infrared absorption spectrum (FTIR), and the results are as follows figure 2 As shown, the typical absorption peaks of graphene and 2-urea-4-[H]-pyrimidinone have been presented on the spectrogram; a certain amount of sample is taken to test X-ray diffraction, and the results are as follows image 3 As shown, there is an obvious peak at θ=9.5° on the spectrum, indicating that after modifying graphene oxide with 2-urea-4-[H]-pyrimidinone, the interlayer spacing between graphene sheets increases.

Embodiment 2

[0030] 1) Preparation of 2-urea-4-[H]-pyrimidinone: Weigh 0.25g of 6-methylisocytosine into a three-necked flask, then add 2.016g of 1,6-hexamethylene diisocyanate, Under the protection of the atmosphere, react at 90°C for 18 hours, then precipitate with petroleum ether with a boiling point of 30-60, separate and dry to obtain 0.54 g of the product 2-urea-4-[H]-pyrimidinone.

[0031] 2) Reaction of 2-urea-4-[H]-pyrimidinone with graphene oxide: Weigh 0.54g of 2-urea-4-[H]-pyrimidinone into a three-necked flask, pour 60ml of anhydrous N, N-dimethylformamide; then add 0.18g of graphene oxide, and ultrasonically disperse the mixture for 60 minutes; After reacting for 12 hours, 0.55 g of the product 2-urea-4-[H]-pyrimidinone-modified graphene was obtained by suction filtration.

[0032] 3) Preparation of three-dimensional structure graphene: disperse the graphene modified by 2-urea-4-[H]-pyrimidinone of 0.55g in anhydrous N,N-dimethylformamide, add 50ml of distilled water, static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com