Method for accelerating aerobic sludge granulation by aid of charcoal

An aerobic sludge and biochar technology, applied in chemical instruments and methods, biological water/sewage treatment, biological treatment devices, etc., can solve the problems of long aerobic granular sludge cultivation period and easy disintegration, and achieve The effect of abundant microorganisms inside the particles, low price, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

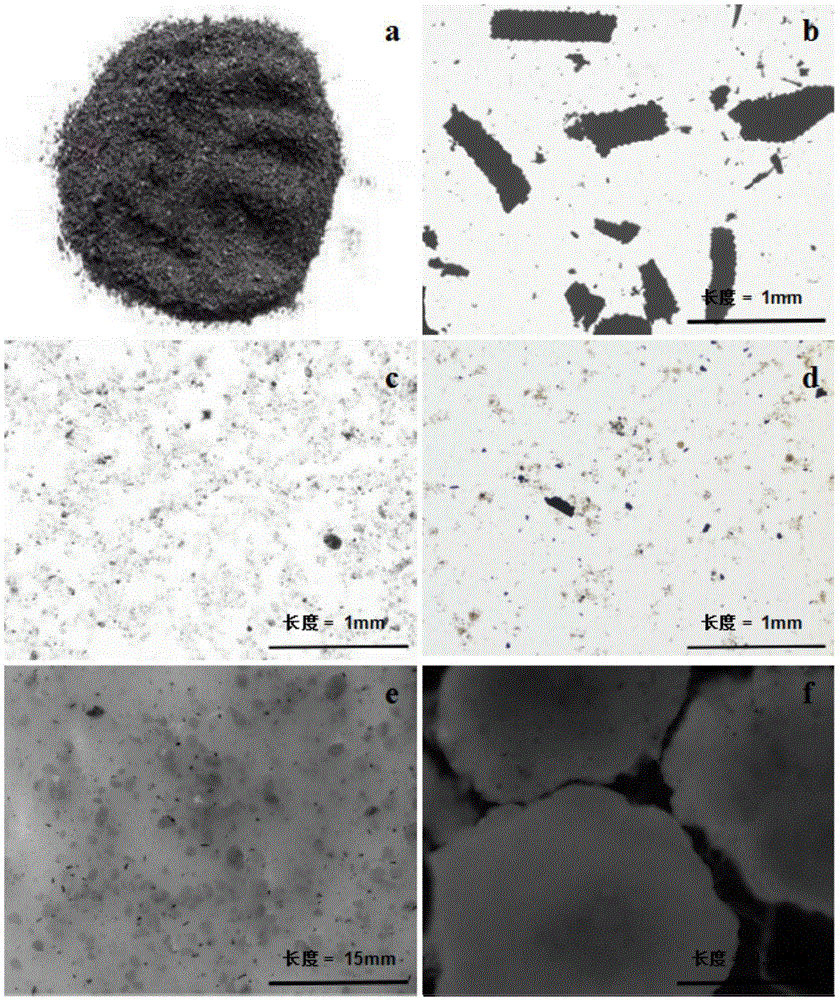

[0023] Embodiment 1: the cultivation of pyridine degraded aerobic granular sludge in SBR reactor

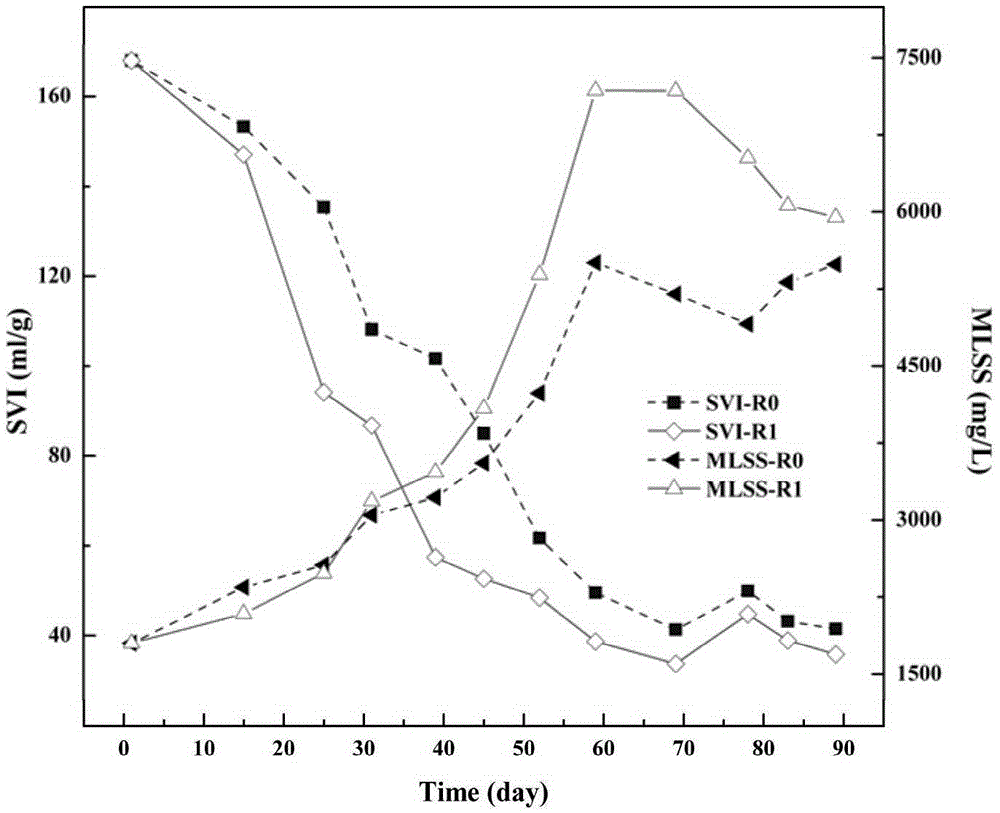

[0024] The present invention utilizes pyridine-degrading high-efficiency bacteria Rhizobiumsp.NJUST18 as a bioenhanced bacterial agent, and biochar as a crystal nucleus to quickly cultivate aerobic granular activated sludge. This example sets up a control experiment. The R0 reactor does not add biochar, and the R1 reactor adds biochar. The rest of the operating conditions are the same. Formation of granular sludge.

[0025] (1) Preparation of Rhizobiumsp.NJUST18 inoculum: Rhizobiumsp.NJUST18 was inoculated into inorganic salt medium MSM supplemented with 1 g / L pyridine, cultured on a shaker for 96 hours, and the bacterial liquid was centrifuged at 8000×g for 10 Minutes will obtain a dry weight of about 2g of thalline deposits as the inoculum of the SBR reactor.

[0026](2) Preparation of biochar: Screen rice bran through a 30-mesh standard sieve, place it in a nitrogen atmosphe...

Embodiment 2

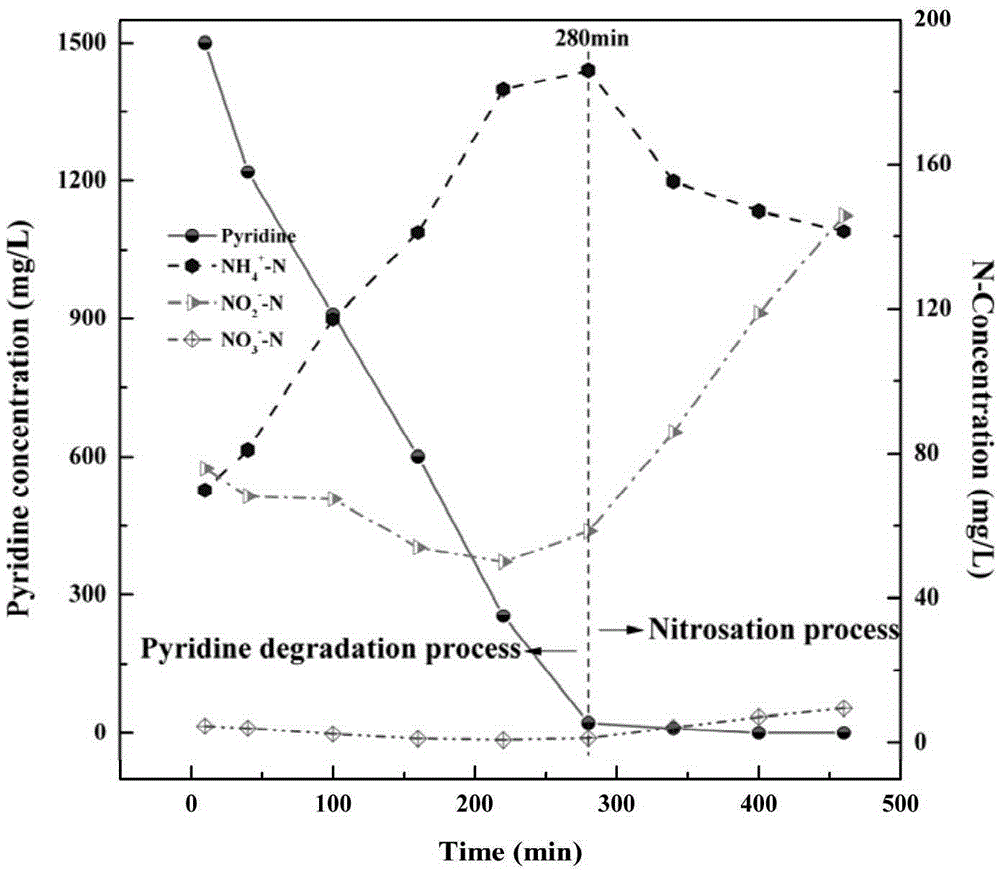

[0035] Example 2: Degradation and short-range nitrification of pyridine by mature aerobic granular sludge

[0036] The waste water was prepared according to the composition of the simulated waste water containing pyridine in Example 1, and the initial concentration of pyridine in the SBR reactor was 1500 mg / L after water inflow. During the operation, the operation period is 8 hours, the water intake time is 5 minutes, the reaction time is 458 minutes, the settlement time is 2 minutes, the drainage time is 5 minutes, the idle period is 10 minutes, and the aeration rate is 100L / h.

[0037] The SBR reactor fed with biochar can realize the complete degradation of pyridine 3 days after start-up, and then the pyridine load gradually increases, and the pyridine degradation ability gradually improves, and nitrosation occurs 75 days after start-up. After 90 days of start-up, mature aerobic granular sludge appeared in the SBR reactor fed with biochar, and the pyridine with an initial co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com