Ultrasonic chemical nickel and phosphorus plating method for NdFeB material

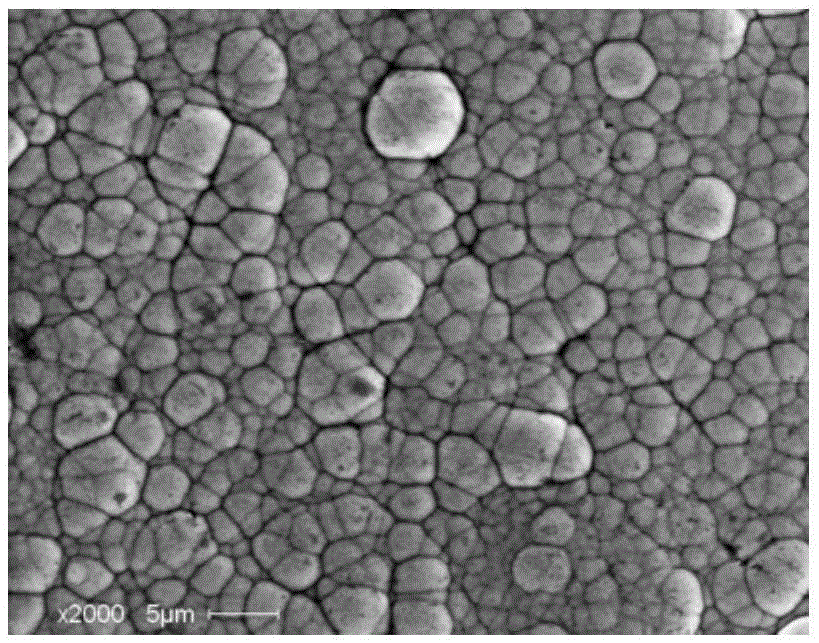

An electroless nickel-phosphorus and ultrasonic technology is applied in the field of electroless plating, which can solve the problems of high energy consumption, fast water volatilization, poor stability, etc., and achieves the effects of uniform and dense coating, low plating temperature, and improved bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (prior art)

[0037] The NdFeB sample used in embodiment 1 is a bonded NdFeB sample, and the specification is a Φ24mm*3mm circular sheet. The electroless nickel-phosphorus plating process of embodiment 1 is as follows:

[0038] Mechanical grinding→ultrasonic degreasing for 10min→pickling and derusting for 30s→activation for 30s→conventional electroless nickel and phosphorus plating.

[0039] Among them, the composition of degreasing liquid in ultrasonic degreasing is: NaOH10g / L, NaOH 3 PO 4 70g / L, Na 2 CO 3 50g / L, emulsifier OP-100.5g / L, the balance is distilled water.

[0040] The composition of pickling and derusting solution is: 65% HNO 3 20ml / L, thiourea 2g / L, and the balance is distilled water.

[0041] The activation formula is 20 g / L of sulfosalicylic acid, 10 g / L of ammonium bifluoride, and the balance is distilled water.

[0042] The composition of nickel-phosphorus plating solution in conventional electroless nickel-phosphorus plating is: N...

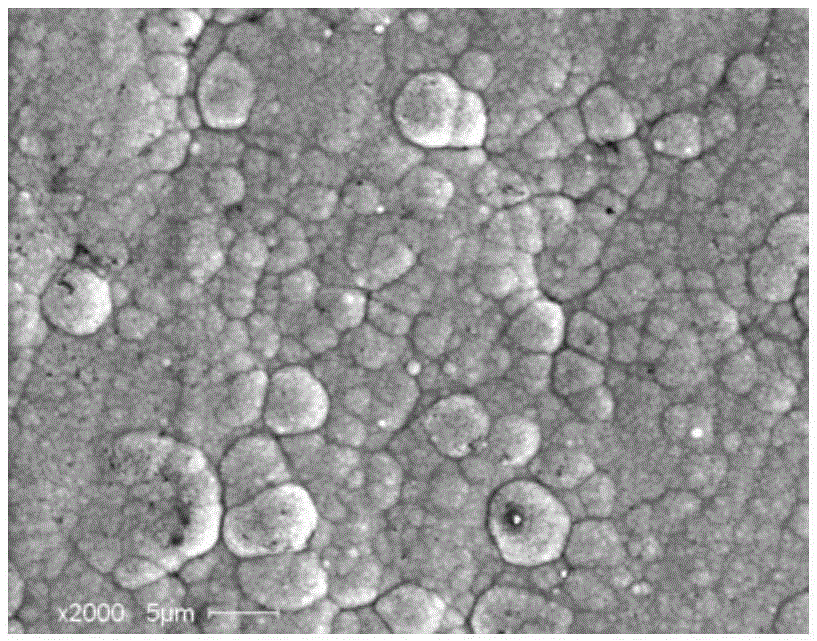

Embodiment 2

[0043] Embodiment 2 (prior art)

[0044] The NdFeB sample that embodiment 2 adopts is bonded NdFeB sample, and specification is Φ 24mm*3mm circular sheet, and the electroless nickel-phosphorous plating process of embodiment 2 is as follows:

[0045] Mechanical grinding→physical sealing→ultrasonic degreasing for 10min→pickling and derusting for 30s→activation for 30s→conventional electroless nickel and phosphorus plating.

[0046] Among them, the composition of degreasing liquid in ultrasonic degreasing is: NaOH10g / L, NaOH 3 PO 4 70g / L, Na 2 CO 3 50g / L, emulsifier OP-100.5g / L, the balance is distilled water.

[0047] The composition of pickling and derusting solution is: 65% HNO 3 20ml / L, thiourea 2g / L, and the balance is distilled water.

[0048] The physical sealing is to use zinc stearate, heat the zinc stearate to 160°C to make it into a molten state, then put the cleaned sample into it, take it out after pressurized immersion for 20 minutes, at this time the surface ...

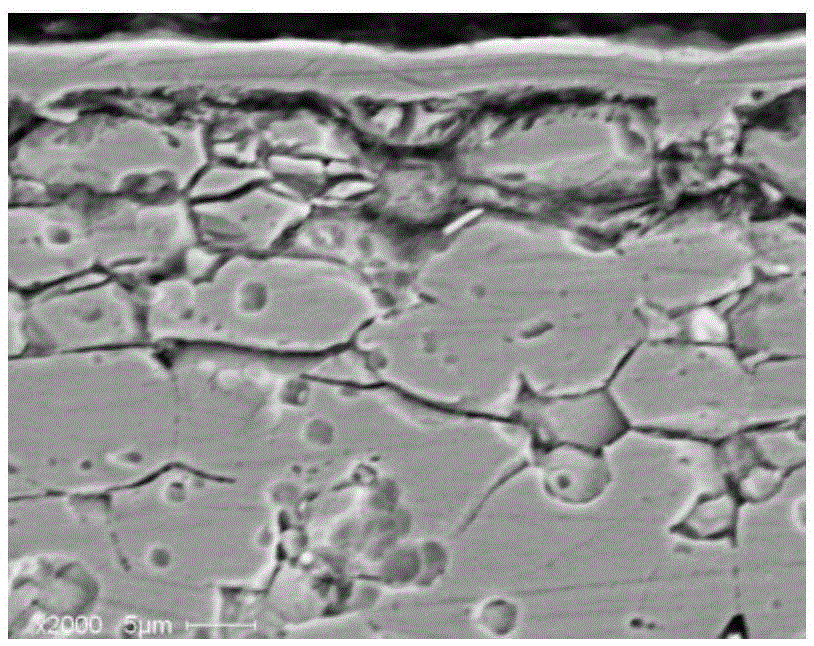

Embodiment 3

[0051] Embodiment 3 (prior art)

[0052] The NdFeB sample used in embodiment 3 is a bonded NdFeB sample, and the specification is a Φ24mm*3mm circular sheet. The electroless nickel-phosphorus plating process of embodiment 3 is as follows:

[0053] Mechanical grinding→Ultrasonic degreasing for 10min→Pickling and rust removal for 30s→Flash plating for 3min→Conventional electroless nickel and phosphorus plating.

[0054] Among them, the composition of degreasing liquid in ultrasonic degreasing is: NaOH10g / L, NaOH 3 PO 4 70g / L, Na 2 CO 3 50g / L, emulsifier OP-100.5g / L, the balance is distilled water.

[0055] The composition of pickling and derusting solution is: 65% HNO 3 20ml / L, thiourea 2g / L, and the balance is distilled water.

[0056] The composition of alkaline bath in flash plating is: NiSO 4 ·6H 2 O25g / L, HEDP60ml / L, thiourea 0.0018g / L, and distilled water as the balance, adjust the pH value of the alkaline solution with NaOH to make the pH of the alkaline solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com