Biomass-based colloidal electrolyte and biomass-based colloidal electrolyte super capacitor

A colloidal electrolyte and supercapacitor technology, which is applied in the manufacture of hybrid/electric double layer capacitors and hybrid capacitor electrolytes, can solve the problems of increased cost and complicated preparation process, and achieve cost saving, simple operation, and easy large-scale industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 3g of sea stone cauliflower and rinse it repeatedly with deionized water, then soak it in deionized water for 2 hours, put it into 300ml of deionized water and heat until the water boils, continue heating for 2 hours, sea stone cauliflower dissolves, and then filter the remaining waste residue Lose. Boil with low heat for 3 hours, evaporate excess water, stop heating, and pour in the prepared KOH electrolyte until the solution is not completely cooled to form sea stone cauliflower-KOH sol (the mass percentage of sea stone cauliflower sol About 30%, the concentration of KOH is 6mol / L).

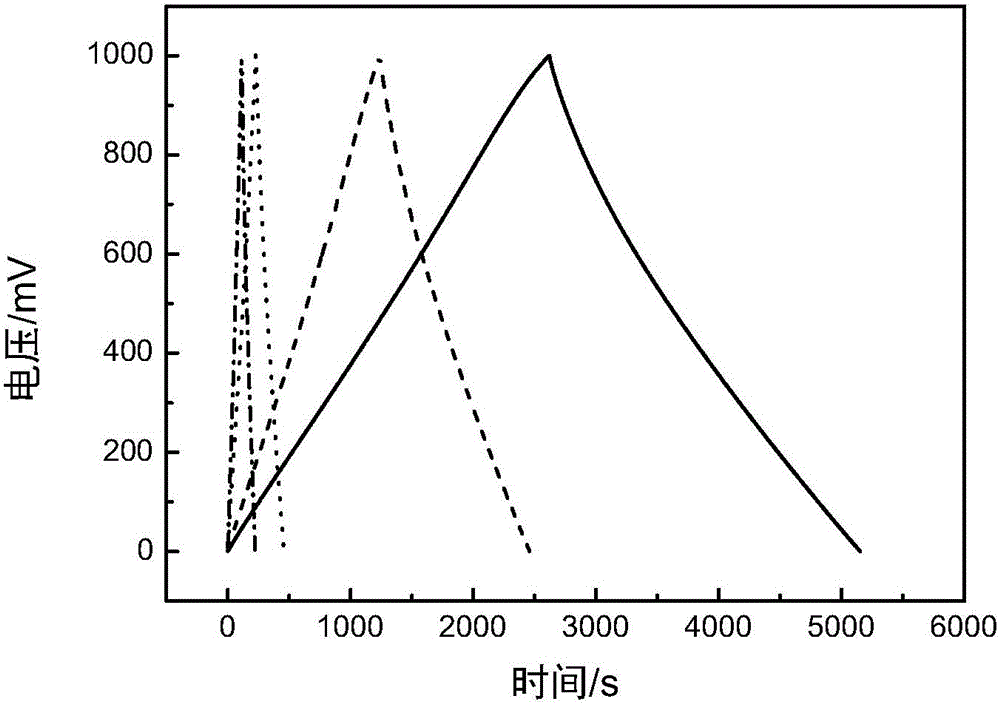

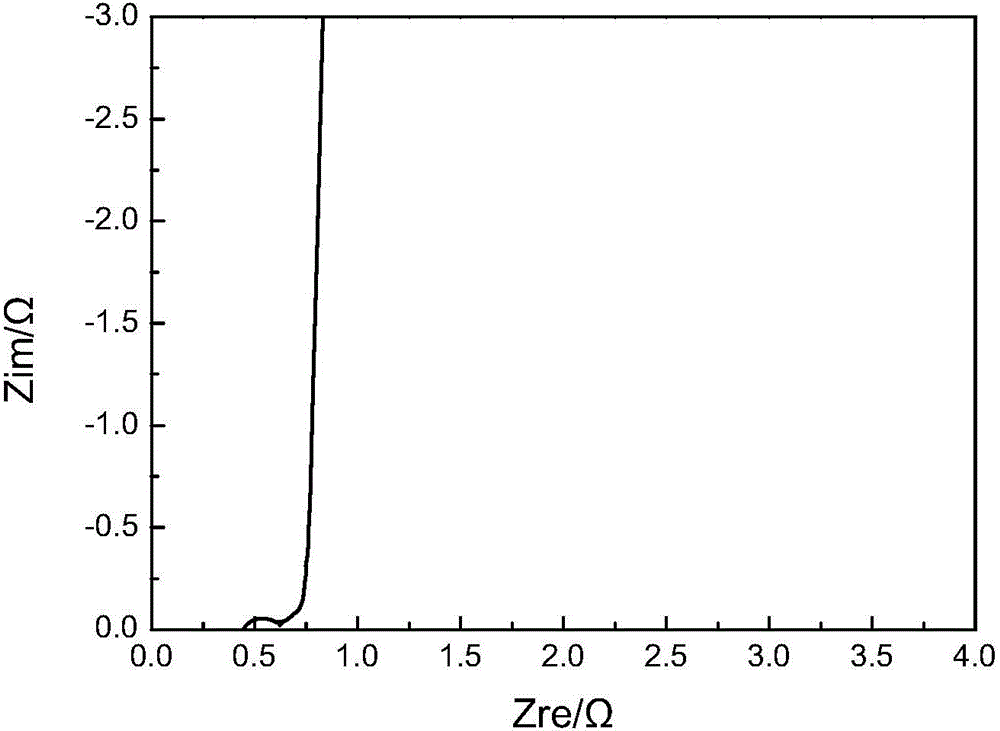

[0039] Mix activated carbon, conductive carbon black and polytetrafluoroethylene binder uniformly according to the mass ratio of 85:10:5, stir well and repeatedly extrude to break the emulsification to obtain a plastic mixture. The resulting mixture was rolled into a film. The dried electrode membrane is cut, and then pressed onto the current collector foamed nickel to obtain an ...

Embodiment 2

[0042] Weigh 3g of sea stone cauliflower and rinse it repeatedly with deionized water, then soak it in deionized water for 2 hours, put it into 500ml of deionized water and heat until the water boils, continue heating for 2 hours, sea stone cauliflower dissolves, and then filter the remaining waste residue Lose. Boil for 4 hours on low heat, evaporate the excess water, stop heating, and pour the prepared Na solution until the solution is not completely cooled. 2 SO 4 Electrolyte, forming sea stone cauliflower-Na 2 SO 4 Sol (wherein the mass percentage composition of seastone cauliflower sol is about 20%, Na 2 SO 4 The concentration is 1mol / L).

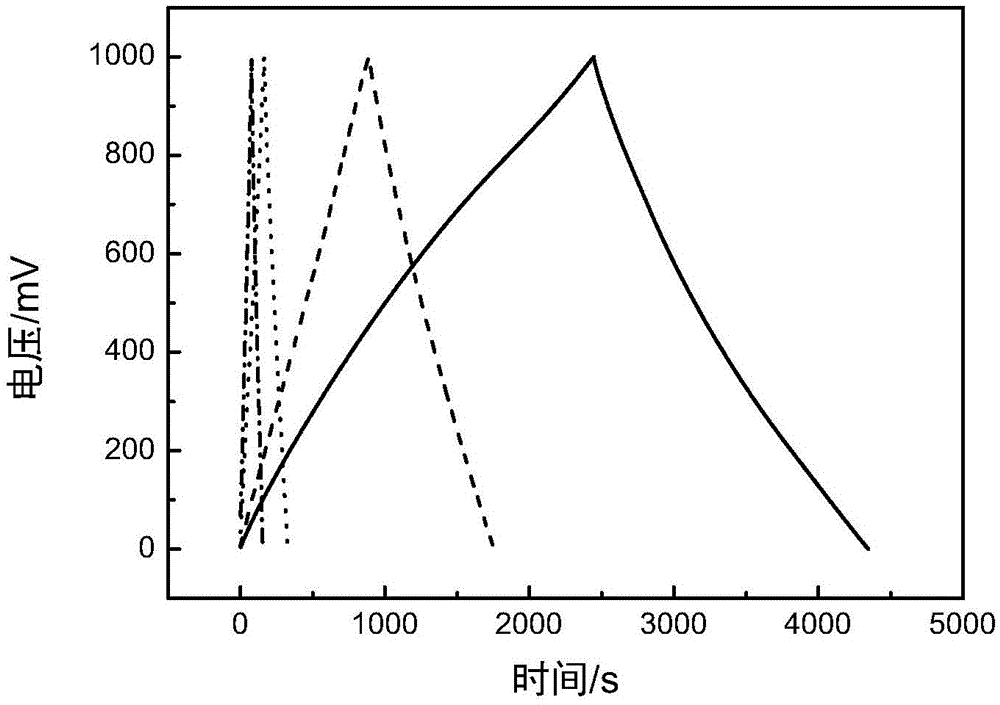

[0043] Mix activated carbon, conductive carbon black and polytetrafluoroethylene binder uniformly according to the mass ratio of 85:10:5, stir well and repeatedly extrude until the emulsification is broken to obtain a plastic mixture. The resulting mixture was rolled into a film. The dried electrode membrane is cut, and then pre...

Embodiment 3

[0046] Weigh 10g of sea stone cauliflower and rinse it repeatedly with deionized water, then soak it in deionized water for 2 hours, put it into 800ml of deionized water and heat until the water boils, continue heating for 3 hours, sea stone cauliflower dissolves, and then filter the remaining waste residue Lose. Boil for 6 hours on low heat, evaporate excess water, stop heating, and pour in the prepared K until the solution is not completely cooled. 4 Fe(CN) 6 Electrolyte to form Seastone Cauliflower-K 4 Fe(CN) 6 Sol (wherein the mass percent composition of seastone cauliflower sol is about 50%, K 4 Fe(CN) 6 The concentration is 0.1mol / L).

[0047] Mix activated carbon, conductive carbon black and polytetrafluoroethylene binder uniformly according to the mass ratio of 85:10:5, stir well and repeatedly extrude until the emulsification is broken to obtain a plastic mixture. The resulting mixture was rolled into a film. After the diaphragm is dried, it is cut, and then th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com