Matrix anodes manufactured by high temperature co-fired multilayer ceramic technology and method thereof

A technology of multi-layer ceramics and high-temperature co-firing, which is applied to the manufacture of electron multiplier anode devices, multiplier electrodes, and cold cathodes. Good consistency, high production efficiency, and the effect of improving unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

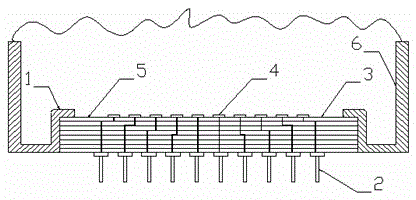

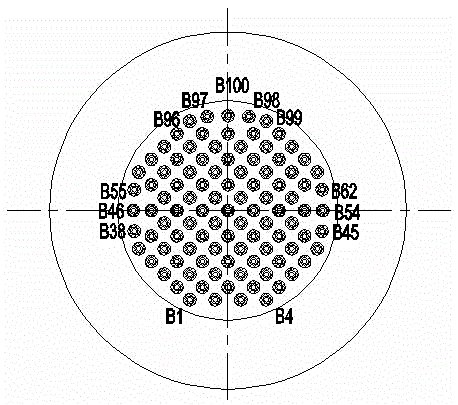

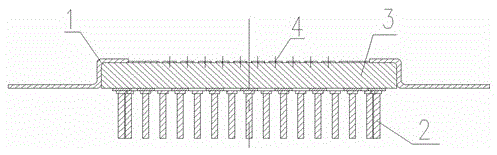

[0047] control figure 1, a 10×10 matrix anode made by high-temperature co-fired multilayer ceramic technology, including: Kovar sealing disc 1; Kovar pin 2; The transition piece between the substrate 3 and the shell is brazed with the multilayer ceramic substrate 3 and sealed with the shell by laser welding or argon arc welding. The multi-layer ceramic substrate 3 is located on the inner surface of the vacuum chamber. On the inner surface of the vacuum chamber is a 10×10 metal contact array 4 uniformly arranged to form an anode input array. On the outer surface of the vacuum chamber is a uniformly arranged 10×10 metal contact array 4. 10 leads out the pin 2 to form an anode output array.

[0048] A method for manufacturing a microchannel plate photomultiplier tube matrix anode using a high-temperature co-fired multilayer ceramic process, comprising:

[0049] Step 1: According to Figure 2, process the Kovar sealing disc 1 with an outer diameter of Φ35.5mm and a height of 2.5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com