Device for flue gas desulfurization and denitrification

A flue gas and denitrification technology, which is applied in the direction of gas treatment, use of liquid separation agent, membrane technology, etc., can solve the problems of long processing time of flue gas desulfurization and denitrification equipment, reduced service life of water pumps, and large water pumping capacity of water pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

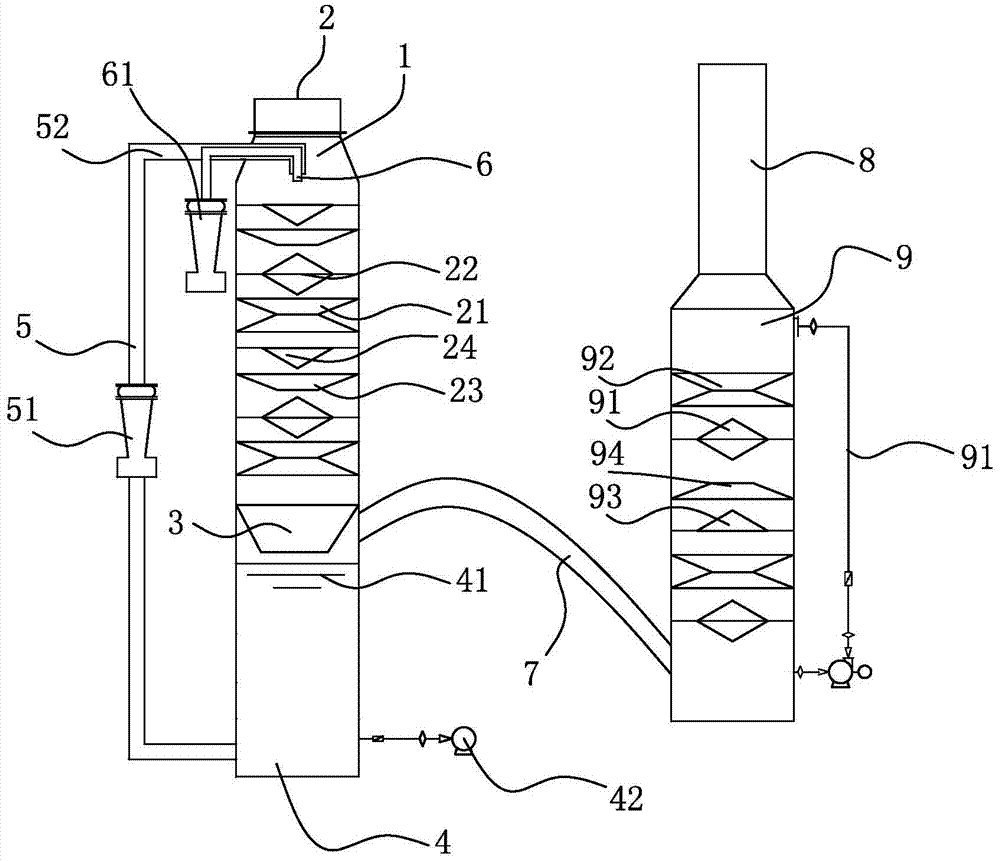

[0014] Combine below figure 1 A detailed description will be made to the specific embodiment of the present invention.

[0015] Such as figure 1 The shown equipment for flue gas desulfurization and denitrification includes a first-stage multiphase reactor 1, a water circulation system 5, an isolation cover 3, a slurry tank 4, a slurry discharge device 42, an outlet pipe 7, and a second-stage multi-phase reactor. Phase reactor 9 and water shower 91.

[0016] The top of the first-stage multiphase reactor is the flue gas inlet 2. The first multiphase reactor 1 includes a conical member composed of the first cone and the first conical ring below it. The cone of the first cone The bottom faces the first conical ring. Both the first conical ring and the first vertebral body have two structures, one is that the diameter of the conical surface of the first conical ring 23 is reduced from top to bottom, and the maximum diameter of the first vertebral body 24 is not less than that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com