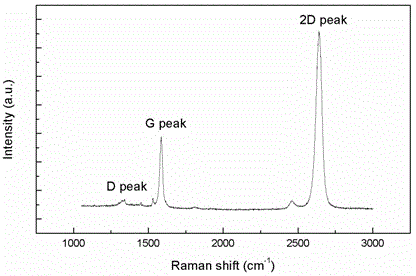

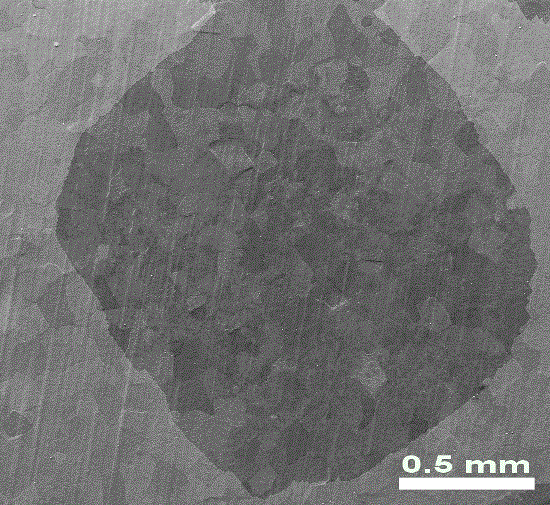

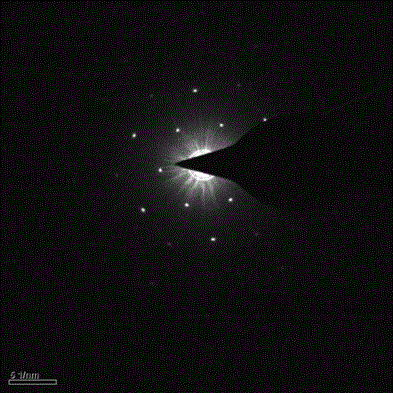

Simple preparation method of millimeter level monocrystalline graphene

A single-crystal graphene, millimeter-scale technology, applied in the field of stable preparation and simplicity, can solve the problems of cumbersome process, reduced advantages, and complexity, and achieve the effect of stable process, low production cost, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] To prepare large-area single-crystal graphene, the specific implementation steps are as follows:

[0034] 1. Weigh 8g solid FeCl with an electronic balance 3 ·6H 2 O, then measure 10ml HCl solution and 100mlH with a graduated cylinder 2 O and stir and mix, ultrasonic treatment for 10min;

[0035] 2. Take out the copper piece and cut it into small pieces of 2cm×2cm, take appropriate amount of polishing liquid and petri dish, use tweezers to put the cut copper piece into the polishing liquid for soaking, soaking time is 25s-50s, and then take it out for use Soak and rinse with deionized water three times, then dry with nitrogen;

[0036] 3. Place the pretreated copper piece on the quartz piece, and then push the quartz piece into the quartz tube with a diameter of 1 inch, so that the quartz piece is in the middle of the quartz tube and the copper piece is in the middle of the quartz tube. Place the quartz tube in the heating furnace after the quartz tube is installed;

[0037] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com