High-specific-surface-area nano barium stannate preparation method

A high specific surface area, barium stannate technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as large-scale application limitations, high equipment requirements, and affecting photoelectric performance. Achieve the effects of easy large-scale industrial production, good repeatability, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

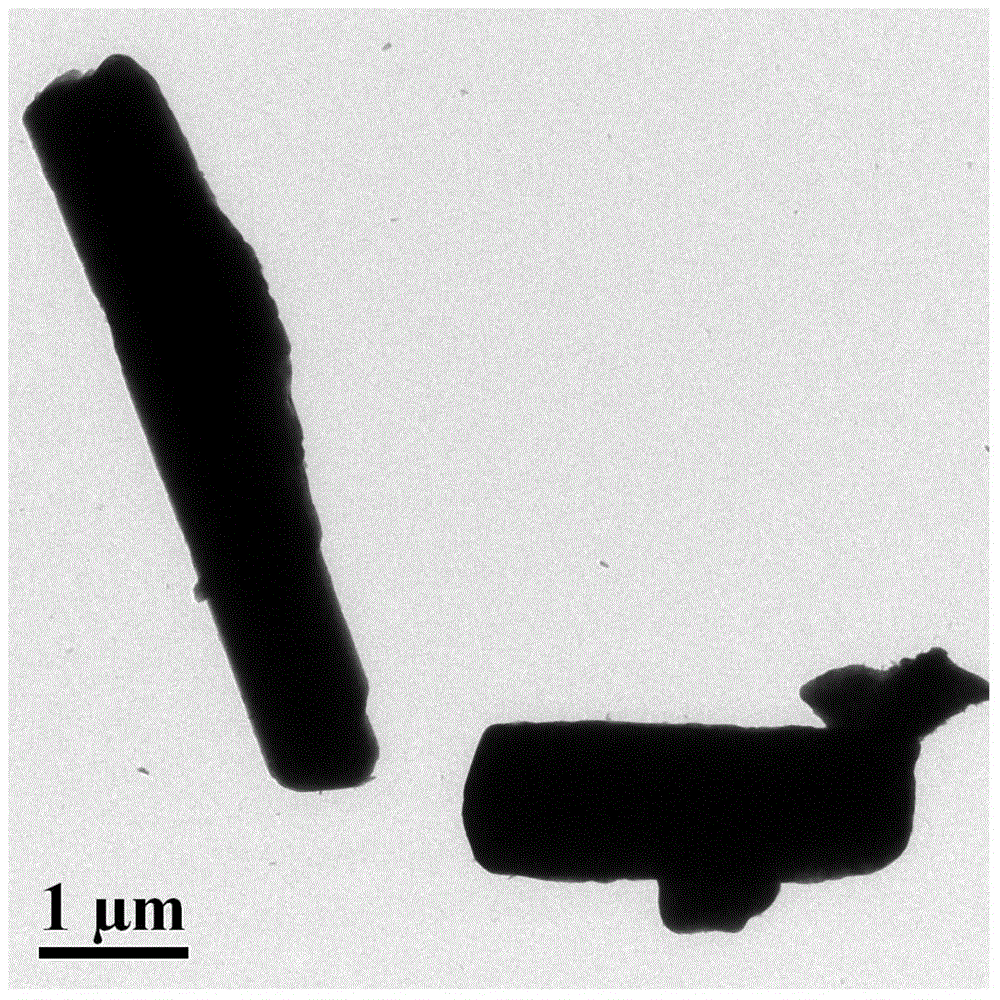

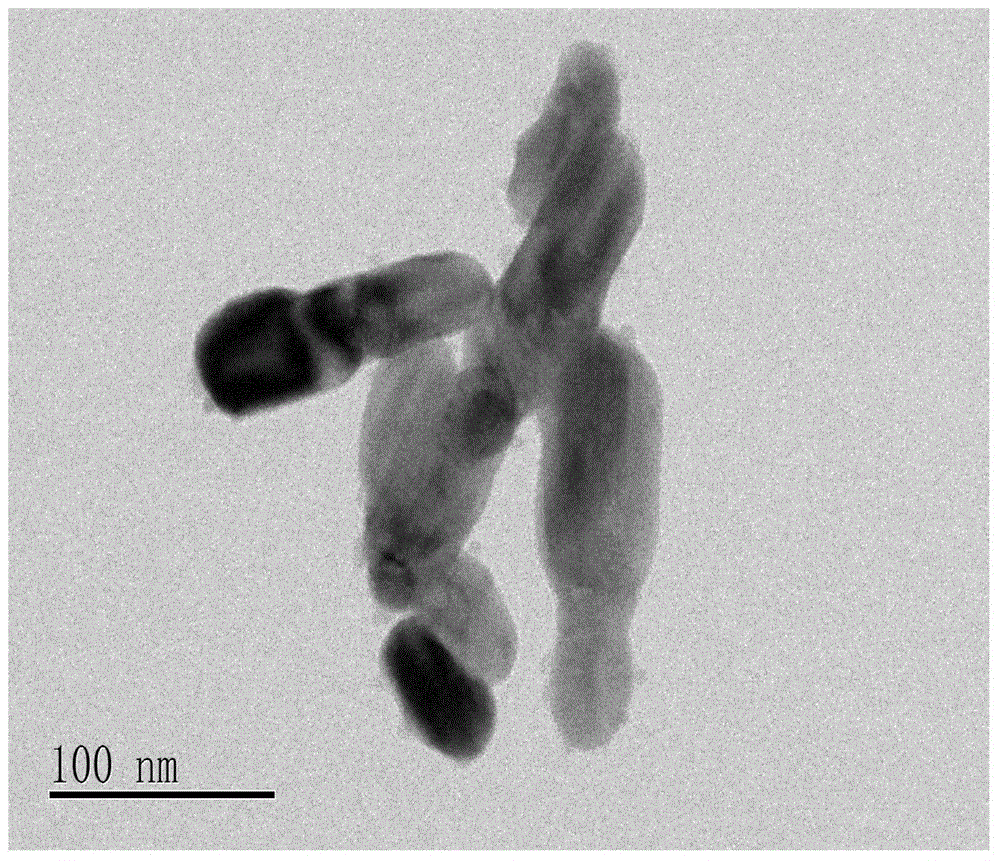

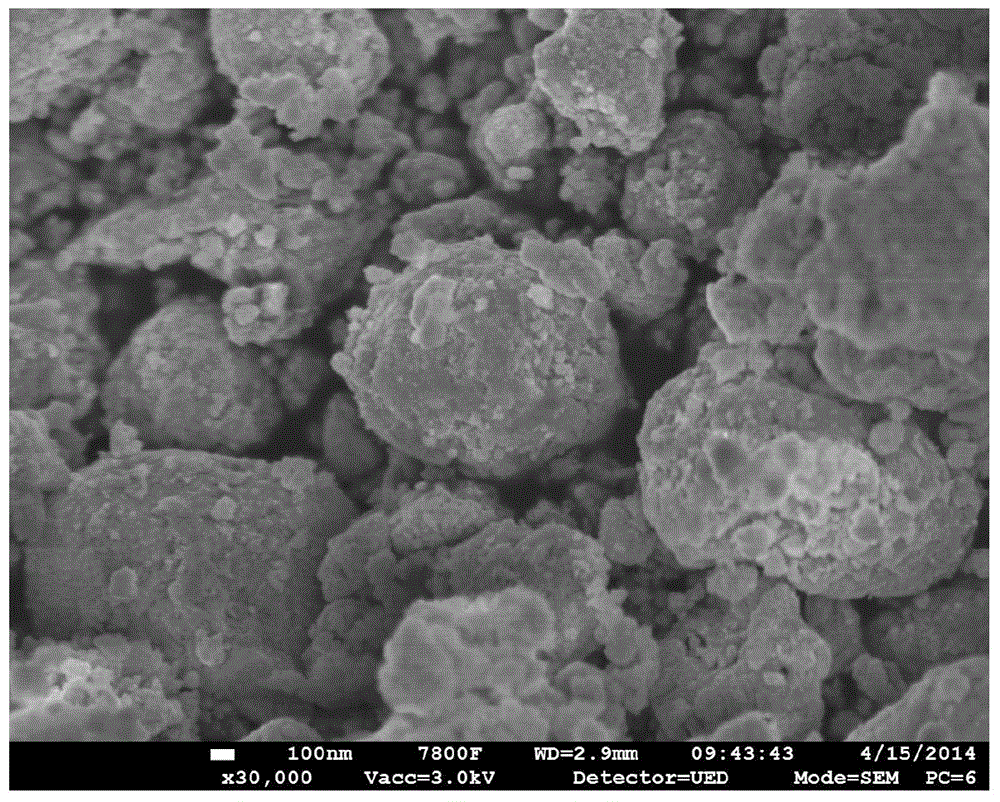

[0019] with SnCl 4 ·5H 2 O is the tin source, which is dissolved in a certain amount of hydrogen peroxide solution with a mass concentration of 10% to 70%, and the pH is adjusted to 7 to 12 with ammonia water with a mass concentration of 28%, so that the SnCl in the solution 4 The final concentration of 0.02 ~ 0.1mol / L, add BaCO to the above solution 3 Powder, so that the Ba / Sn molar ratio is between 0.95:1 and 1.05:1, stir and react at 20-100°C for 0.5-24h, filter and wash until the pH of the filtrate is 6.5-7.5, dry at 60-120°C for 5- After 24 hours, the obtained powder is calcined at 500-800° C. for 0.5-4 hours to obtain high-purity barium stannate nanoparticles. The prepared BaSnO 3 See Examples 1-27 for details.

[0020] Table 1. Barium stannate nanoparticles prepared under different synthesis conditions

[0021]

[0022]

[0023] Note: The grain size in Table 1 is calculated by the Scherrer formula; the specific surface area in Table 1 is measured by a physica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com