A kind of technique for preparing cefathiamidine

A cefathiamidine and process technology, applied in the field of chemical drug synthesis, can solve the problem of high residual amount of impurities, achieve the effects of high reaction yield, avoid side reactions and reduce the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

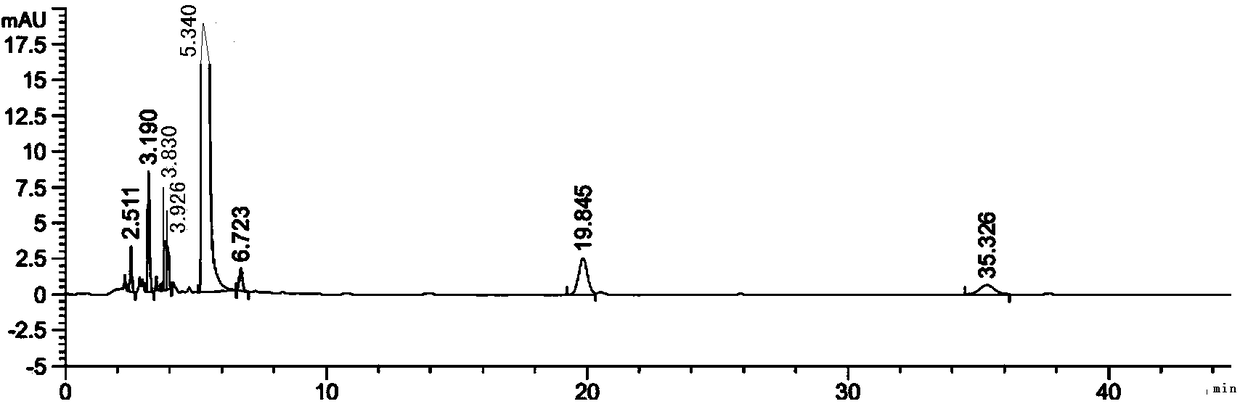

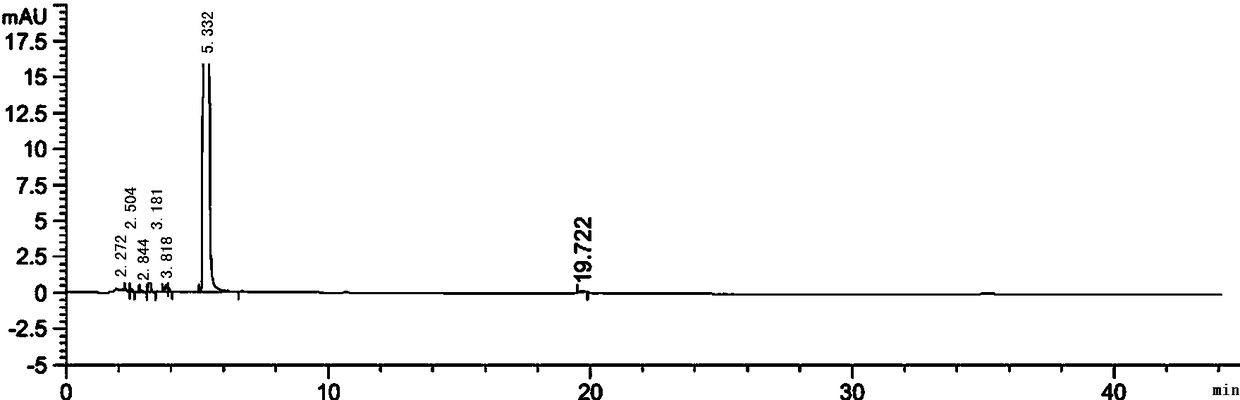

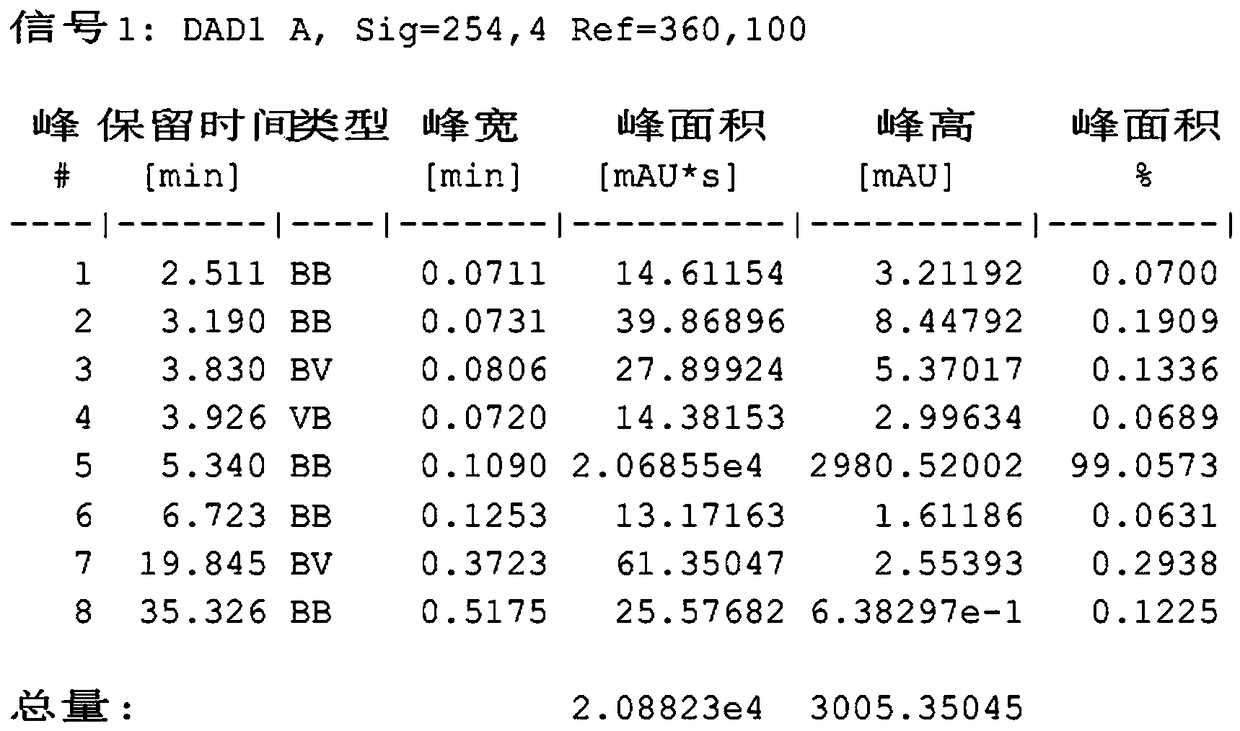

Examples

Embodiment 2

[0039]In a 10L reactor, add DCM 5320 g (4L), TEA (200mL), bromoacetyl-7ACA 500g in sequence, stir to dissolve, add co-solvent pure water 50mL, then add N,N-diisopropylthiourea 225 g. After stirring and dissolving, heat the reaction liquid to reflux. After reacting for 2-3 hours, stop the reaction and lower the internal temperature to 0°C-15°C. Add 2L of acetone dropwise, stir and crystallize. After the dropwise addition, keep stirring at 8-12°C and filter with suction. After the filter cake is drained, add 1L of acetone to rinse the filter cake. After draining, add the filter cake to 10L Then add 600mL of pure water and stir to dissolve, then add 1080 g (1.2L) of ethyl acetate, stir for 10 minutes, extract impurities, after standing for layers, filter the water layer into the crystallization reactor, and use dilute Adjust the pH of the solution to 5.0 with hydrochloric acid, cool the obtained clear mixed solution to 0-5°C, add 5.6L of acetone dropwise, after the dropwise addit...

Embodiment 3

[0041] Add 400 mL of DCM, 18 mL of TEA, and 50 g of bromoacetyl-7ACA to a 1L reaction flask in sequence, stir to dissolve, add 10 mL of co-solvent pure water, then add 22.5 g of N,N-diisopropylthiourea, and stir to dissolve Afterwards, heat the reaction liquid to reflux, react for 2-3 hours, stop the reaction, add 10 mL of pure water as a co-solvent, and lower the internal temperature to 10°C to 15°C. Add 200mL of acetone dropwise, stir and crystallize. After the dropwise addition, keep stirring at 8-12°C and filter with suction. After the filter cake is drained, add 100mL of acetone to rinse the filter cake. into the reaction flask, then add 60 mL of pure water and stir to dissolve, then add 108 g (120 mL) of ethyl acetate, stir for 10 minutes, extract impurities, stand to separate the layers, filter the water layer into the crystallization reaction flask, and use dilute Adjust the pH of the solution to 4.5 with hydrochloric acid, cool the obtained clear mixed solution to 0-5...

Embodiment 4

[0043] Add 400 mL of DCM, 20 mL of TEA, and 50 g of bromoacetyl-7ACA to a 1L reaction flask in sequence, stir to dissolve, then add 22.5 g of N,N-diisopropylthiourea, stir to dissolve, then heat the reaction solution to reflux , After reacting for 2-3 hours, stop the reaction and lower the internal temperature to 10°C to 15°C. Add 200mL of acetone dropwise, stir and crystallize. After the dropwise addition, keep stirring at 8-12°C and filter with suction. After the filter cake is drained, add 100mL of acetone to rinse the filter cake. Then add 60 mL of pure water and stir to dissolve, then add 108 g (120 mL) of ethyl acetate, stir for 10 minutes, extract impurities, stand to separate layers, filter the water layer into the crystallization reaction bottle, and use dilute Adjust the pH of the solution to 5.0 with hydrochloric acid, cool the obtained clear mixture to 0-5°C, add 560mL of acetone dropwise, after the dropwise addition, keep stirring at 0-5°C for 30min, filter with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com