Steel smelting process used for automobile hub bearing

A technology for smelting automobile wheels and steel, which is applied in the field of metallurgy, can solve the problems of low production efficiency of die casting process, increase material production cost, affect the purity of molten steel, etc., reduce the content of non-metallic inclusions, reduce the chance of oxidation slag, The effect of reducing the chance of absorbing N

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

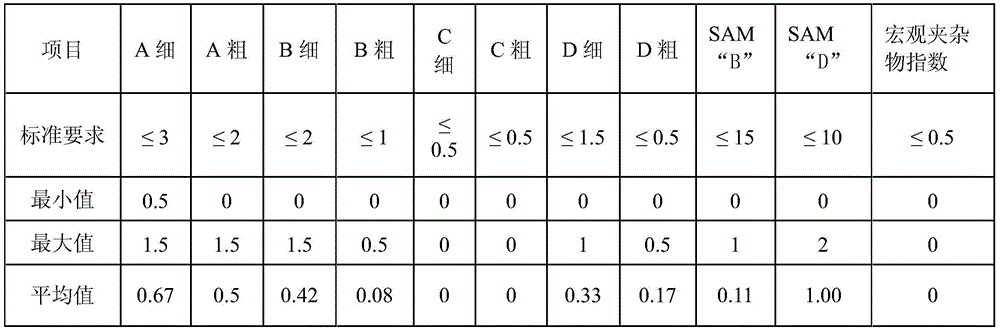

[0034] A kind of steel for automobile hub bearings, which is produced by the process route of "converter smelting → LF furnace refining → RH vacuum furnace treatment → continuous casting machine pouring". The purity control method of the molten steel is as follows:

[0035] Converter process

[0036] 1. The loading capacity of a converter with a nominal volume of 120t is 133.8t, including 117.5t of molten iron, 16.3t of scrap steel, 0.53% carbon content at the end of the converter, tapping temperature of 1647°C, and tapping volume of 120.6t.

[0037] 2. Add 100kg of aluminum cake, 100kg of low-nitrogen recarburizer, corresponding amount of ferroalloy, 700kg of low-Ti pre-melted refining slag, and 500kg of lime during the tapping process of the converter.

[0038] LF refining furnace process

[0039]1. In the early stage, SiC100Kg / furnace and aluminum particles 50Kg / furnace are used for diffusion deoxidation of slag. In the early stage, large argon gas flow is used, and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com