Method for detecting copper, iron and calcium in flash converting furnace slag

A detection method and slag technology, applied in the direction of chemical analysis by titration, can solve the problems of long analysis process, slow analysis speed, long single element determination process, etc., and achieve the effect of simple method and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

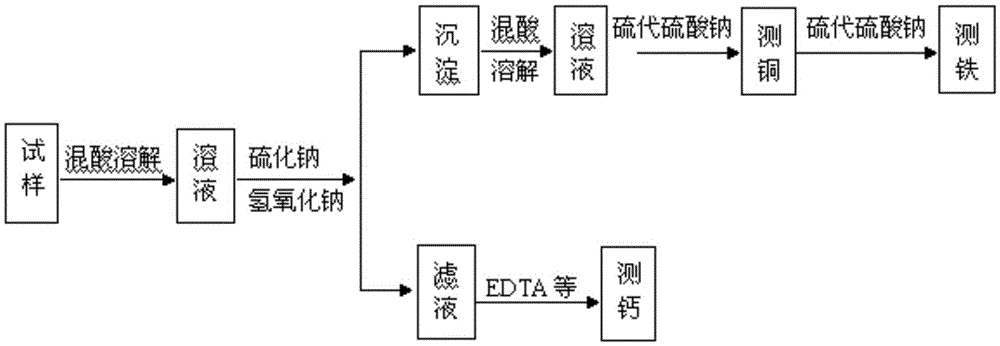

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 precision experiment

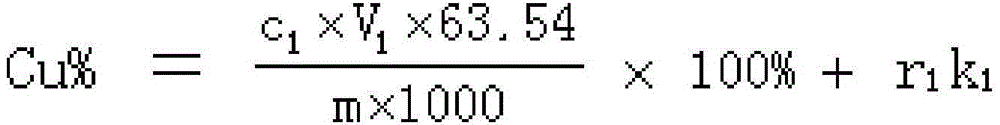

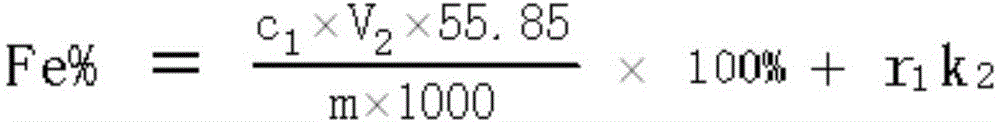

[0078] (1) Determination of copper:

[0079] Take flash blowing furnace slag as the sample, weigh 0.4000g (m) of the sample and place it in a 250mL conical beaker, add a small amount of water to soak the sample, add 15mL of hydrochloric acid, heat at low temperature and boil for 3 to 5 minutes, cool slightly , then add 10mL of nitric acid and 5mL of sulfuric acid, continue heating until evaporated to dryness, and cool.

[0080]Add 40 mL of water into the above-mentioned conical beaker, heat slowly, and add sulfuric acid solution with a mass concentration of 50%, so that the pH value of the obtained first solution is 2-3. Slightly cool, slowly add 20mL100g / L sodium sulfide solution, slightly boil for 10min. Cool slightly, stir and slowly add dropwise a sodium hydroxide solution with a mass concentration of 20%, until the red precipitate in the solution no longer increases. Cool slightly, let stand for 5 minutes, filter, wash the pre...

Embodiment 2

[0093] Embodiment 2 Accuracy experiment

[0094] 1. Carry out the accuracy test on the flash converting slag samples, namely detect the copper, iron and calcium content in the 3 flash converting slag samples by the method in Example 1. The detection results are shown in Table 2, and Table 2 is the result of the accuracy experiment of the embodiment of the present invention.

[0095] 2. Determination of copper by existing methods: iodometric method

[0096] Weigh 0.3000g sample, place it in a 250mL conical beaker, moisten it with a small amount of water, add 5mL nitric acid and 15mL hydrochloric acid, cover the watch glass, heat at low temperature to dissolve completely, steam until nearly dry, remove and cool slightly. Add 50mL of water and 10mL of sulfuric acid, boil, and slowly add 25mL of 200g / L sodium thiosulfate solution dropwise with stirring until a large amount of precipitation occurs, and filter while hot. Wash the precipitate with hot water for more than 3 times to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com