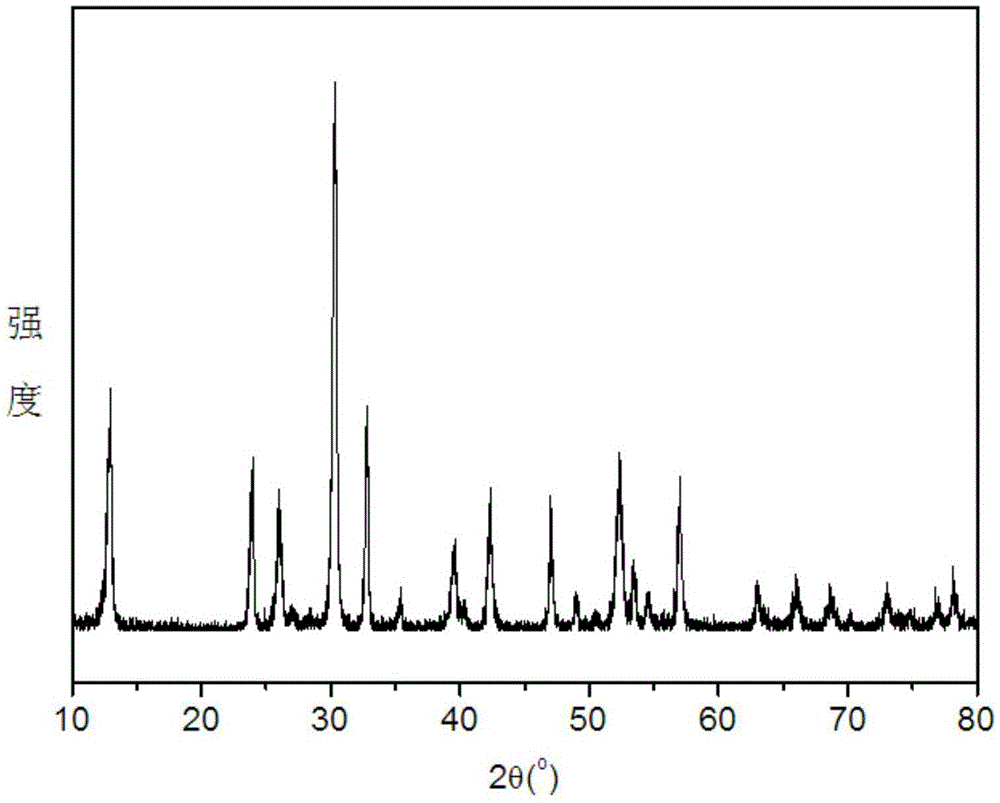

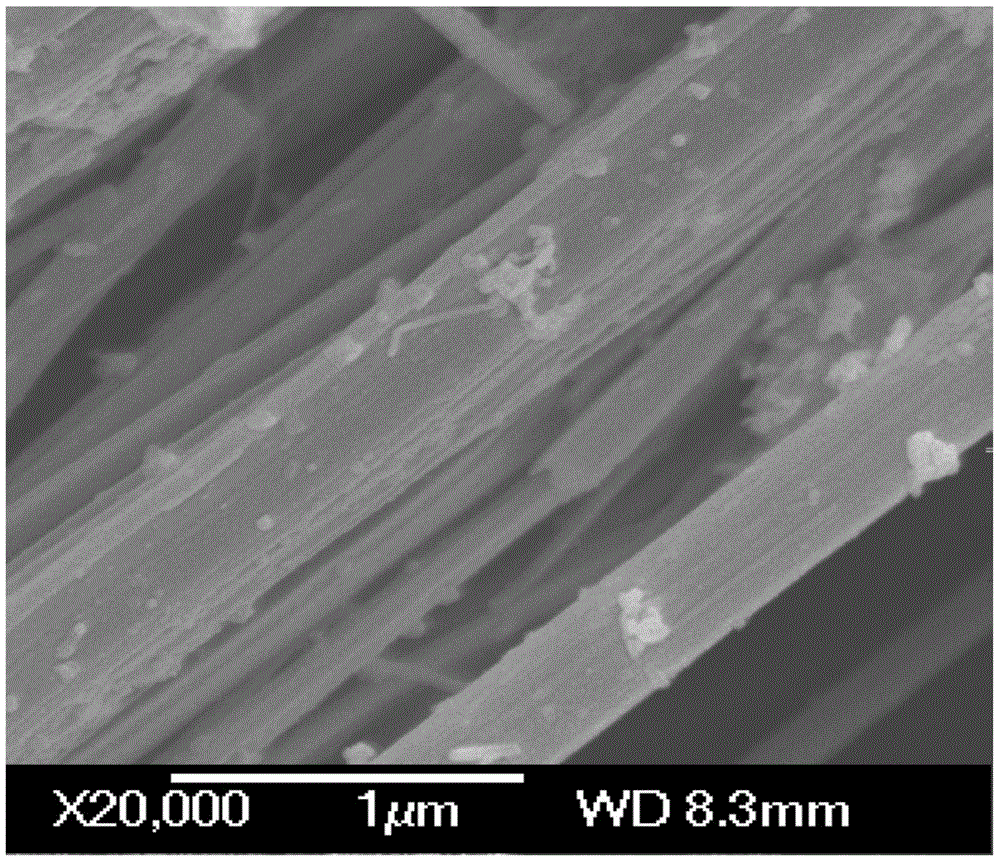

Preparation method of bismuth subcarbonate nanoribbon

A technology of bismuth oxycarbonate nanometer and deionized water, which is applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., and can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Mix ethanolamine and deionized water in a volume ratio of 0.8:1, and magnetically stir for 7 minutes to obtain a mixed solution;

[0032] Step 2: Put Bi(NO 3 ) 3 ·5H 2 O was added to the above mixed solution, and after magnetic stirring for 25 min, ultrasonic treatment was performed for 13 min to obtain a white suspension, which was the hydrothermal reaction precursor. Bi(NO) in the precursor solution 3 ) 3 The concentration of 0.1mol / L;

[0033] Step 3: transfer the precursor liquid into the hydrothermal reactor, the filling rate of the hydrothermal reactor is 74%, put it into a constant temperature blast drying oven, and stop the reaction after keeping the temperature at 140 ° C for 16 hours;

[0034] Step 4: After the reaction temperature dropped to room temperature, the hydrothermal reactor was taken out, the white precipitate obtained by the reaction was separated by centrifugation, the precipitate was washed with deionized water and absolute ethanol u...

Embodiment 2

[0036] Step 1: Mix ethanolamine and deionized water in a volume ratio of 1:1, and magnetically stir for 6 minutes to obtain a mixed solution;

[0037] Step 2: Put Bi(NO 3 ) 3 ·5H 2 O was added to the above mixed solution, and after magnetic stirring for 22 min, ultrasonic treatment for 12 min was performed to obtain a white suspension, which was the hydrothermal reaction precursor. Bi(NO) in the precursor solution 3 ) 3 The concentration of 0.08mol / L;

[0038] Step 3: transfer the precursor liquid into the hydrothermal reaction kettle, the filling rate of the hydrothermal reaction kettle is 72%, put it into a constant temperature blast drying oven, and keep the temperature at 130 ° C for 18 hours to stop the reaction;

[0039] Step 4: After the reaction temperature drops to room temperature, the hydrothermal reactor is taken out, the white precipitate obtained by the reaction is separated by centrifugation, washed with deionized water and absolute ethanol until neutral, a...

Embodiment 3

[0041] Step 1: Mix ethanolamine and deionized water in a volume ratio of 1.5:1, and magnetically stir for 5 minutes to obtain a mixed solution;

[0042] Step 2: Put Bi(NO 3 ) 3 ·5H 2 O was added to the above mixed solution, and after magnetic stirring for 20 min, ultrasonic treatment was performed for 10 min to obtain a white suspension, which was the hydrothermal reaction precursor. Bi(NO) in the precursor solution 3 ) 3 The concentration of 0.05mol / L;

[0043] Step 3: transfer the precursor liquid into a hydrothermal reaction kettle, the filling rate of the hydrothermal reaction kettle is 70%, put it into a constant temperature blast drying oven, and stop the reaction after keeping the temperature at 120 ° C for 20 hours;

[0044] Step 4: After the reaction temperature drops to room temperature, the hydrothermal reactor is taken out, the white precipitate obtained by the reaction is separated by centrifugation, the precipitate is washed with deionized water and absolute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com