Method for reconcentrating and recycling reverse osmosis concentrated brine in reclaimed water recycling device

A technology of reverse osmosis and concentrated brine, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of membrane scaling, low recovery rate, membrane pollution, etc., to avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

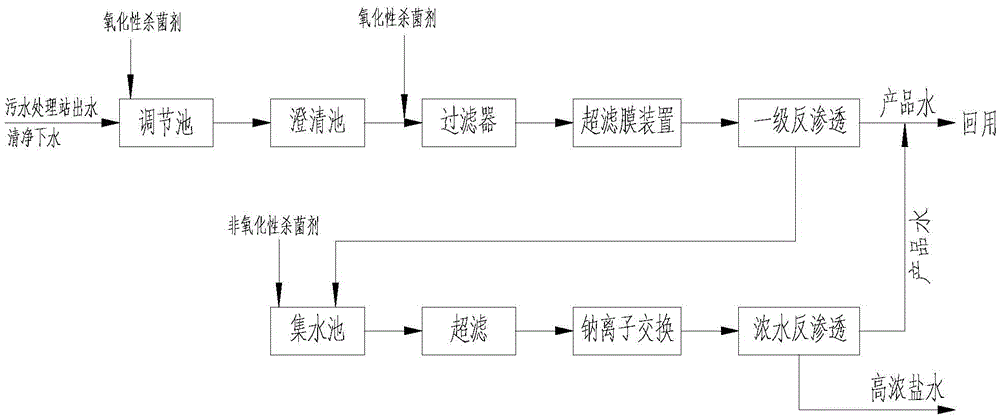

Image

Examples

Embodiment 1

[0026] The effluent and clean water from the sewage treatment station are combined into the regulating tank, and the water quality and quantity are adjusted in the regulating tank. At the same time, fungicides, such as chlorine dioxide or sodium hypochlorite, are added to the regulating tank at a dosage of 10-15 mg / L, and the effluent of the regulating tank is monitored. The residual chlorine reaches 1-2mg / L; the effluent from the regulating tank flows into the clarification tank, and according to the hardness of the water, caustic soda and soda ash are added to the water after calculation to remove most of the hardness in the water, and the sludge produced in the clarification tank is sent to the sludge dewatering center for further processing Dehydration, the press filtrate returns to the regulating tank;

[0027] The effluent from the clarification tank enters the filter to remove most of the suspended solids and particulate matter. The backwash drainage of the filter is col...

Embodiment 2

[0032] A method for reconcentrating and reusing reverse osmosis concentrated brine in a reclaimed water recycling device, comprising the following steps:

[0033] (1) The effluent and clean sewage from the sewage treatment station are merged into the regulating pool, and the water quality and quantity are adjusted in the regulating pond. At the same time, fungicides are added to the regulating pond at a dosage of 10-15mg / L, and the residual chlorine in the effluent of the monitoring and regulating pond reaches 1 ~2mg / L;

[0034] (2) The effluent of the regulating tank flows into the clarification tank. According to the hardness of the water, caustic soda and soda ash are added to the water after calculation, and most of the hardness in the water is formed by chemical reaction. The hardness of the effluent of the clarification tank is: 50-80 mg in terms of calcium carbonate / L, the sludge produced in the clarifier is sent to the sludge dewatering center for dehydration, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com