Aspergillus niger-spores for converting glucose to produce gluconic acid and preparation and application method of aspergillus niger-spores

A technology of Aspergillus niger spores and gluconic acid is applied in biochemical equipment and methods, methods of using spores, methods based on microorganisms, etc., to achieve the effects of simple preparation method, simple composition and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 relevant culture medium

[0031] 1) PDA medium Wash the potatoes, peel them, cut them into small pieces, then weigh 200g, add water and boil until rotten (boil for 20-30min, it can be pierced by a glass rod), filter with eight layers of gauze, heat, Then add 15g of agar according to the actual experiment needs, continue heating and stirring to mix evenly, after the agar is dissolved, add glucose, stir evenly, and then make up water to 1000mL after cooling down a bit, divide into test tubes or Erlenmeyer flasks, add stoppers, bandage, 121°C After sterilizing for about 20 minutes, take out the test tube and place it on an inclined plane to obtain the PDA medium, cool it and store it for later use.

[0032] 2) Buckwheat seed culture medium Buckwheat seeds (300g) are washed with deionized water, boiled with an equal amount of deionized water, softened in a boiling water bath (100°C, 15min), poured off excess water, and packed in conical In t...

Embodiment 2

[0033] Example 2 Acquisition of Aspergillus niger spores (derived from Aspergillus niger ATCC9029, purchased from the American type culture integration library, but not limited to this strain)

[0034] Aspergillus niger was inoculated on the PDA medium slant, and cultivated for 7 days at 30°C; the Aspergillus niger PDA culture slant was washed with sterilized deionized water containing 0.1% Tween-80 (or Tween-20), to obtain the Aspergillus niger spore suspension, and Nephelometric method adjusted to a concentration of 10 8 spores / mL of the spore suspension, which was inoculated in the buckwheat seed medium (the inoculum size was 10 8 spores / 100g buckwheat seeds), cultivated for 200h. Add sterilized deionized water containing 0.1% Tween-80 (or Tween-20) to the buckwheat seed medium that has cultivated Aspergillus niger for 200h, shake at 180rmp for 1h, filter it with sterile gauze under aseptic conditions, and collect The filtrate was centrifuged at 10,000 g for 10 minutes, t...

Embodiment 3

[0035] The processing of embodiment 3 Aspergillus niger spores

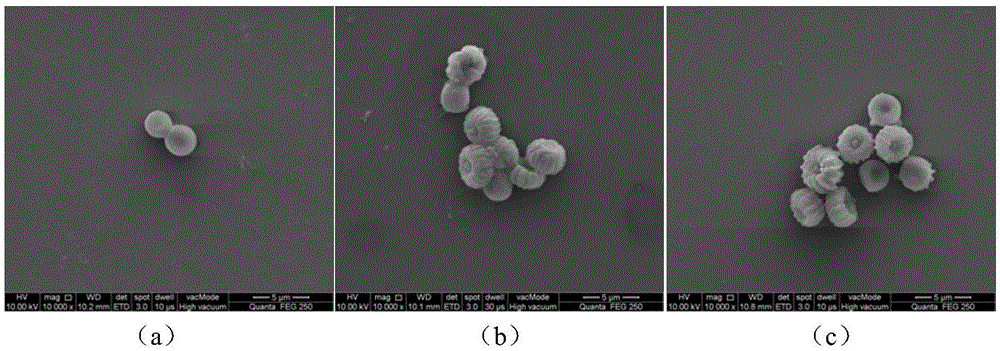

[0036] The Aspergillus niger spore obtained above, because its spore wall is its natural barrier, has hindered the contact of glucose and intracellular glucose oxidase, therefore, to process Aspergillus niger spore, the method is:

[0037]1. Add sterilized deionized water containing 0.1% Tween-80 (or Tween-20) to the Aspergillus niger spore precipitate, centrifuge at 10,000g, 4°C for 10min, discard the supernatant, collect the lower precipitate, repeat the above After the step n times (1≤n≤25), the spores are collected for use.

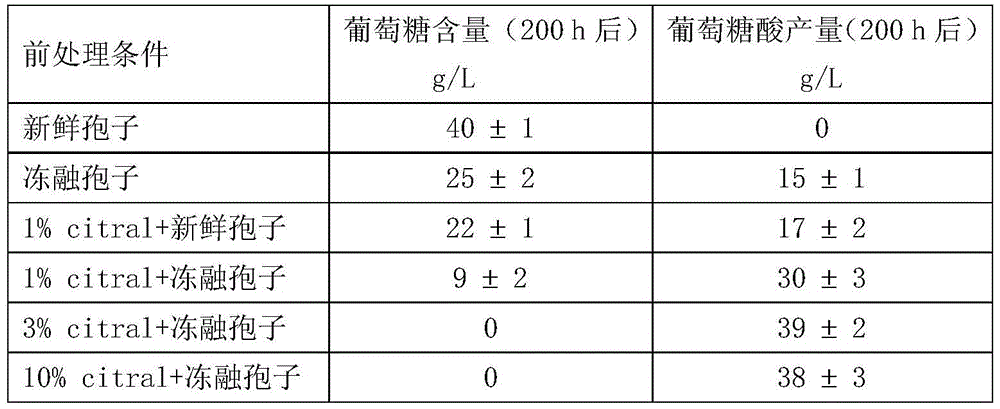

[0038] 2. Put the obtained Aspergillus niger spore precipitate into -20℃ refrigerator, -80℃ low-temperature refrigerator or liquid nitrogen tank for more than 48 hours, then take it out from the refrigerator, let it dissolve rapidly at room temperature, and add a certain concentration Terpenoids (citral in this example) are treated for a certain period of time (3-18h), and the spores ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com