Preparation method of bromine-lead-cesium single crystals

A bromine-lead-cesium single crystal technology is applied in the field of preparation of bromine-lead-cesium single crystals for room temperature nuclear radiation detectors. The effect of single crystal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 is 8mm with diameter, and the preparation of the bromine-lead-cesium single crystal that length is 50mm is an example illustration;

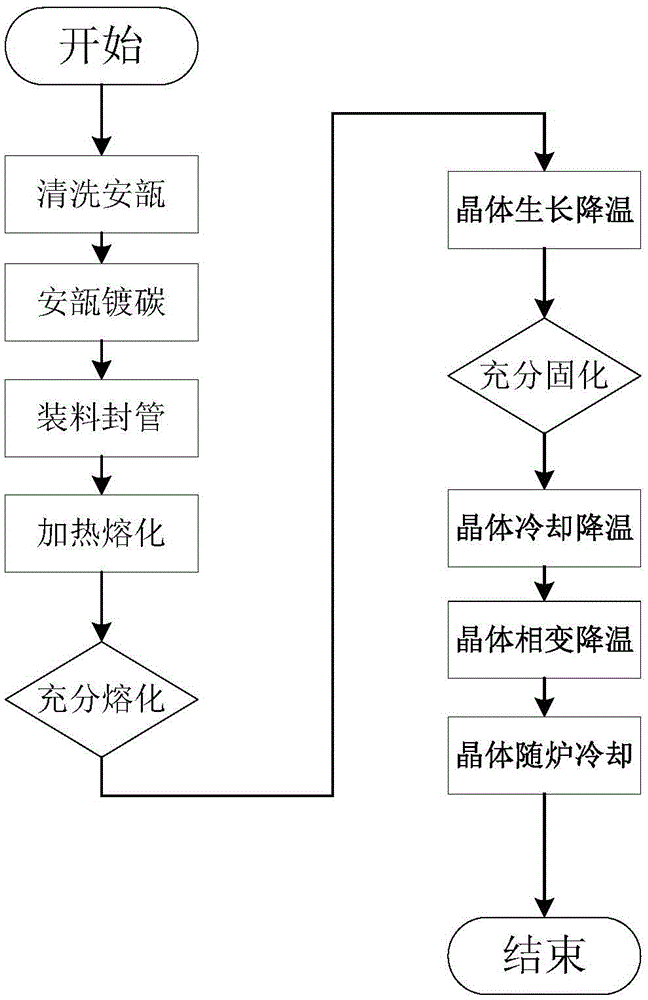

[0061] In embodiment 1, adopt internal diameter to be the cylindrical quartz ampoule of 8mm, one end is the conical shape that cone angle is 20 °; The preparation process of bromine lead cesium single crystal among the embodiment 1 is set forth in detail below;

[0062] Step 1: Clean the quartz ampoule as follows:

[0063] (1.1) Soak the quartz ampoule with aqua regia (concentrated hydrochloric acid:concentrated nitric acid=3:1) for 24 hours, and rinse the soaked ampoule with deionized water above 10MΩ;

[0064] (1.2) Soak the washed quartz ampoule with 5% dilute hydrofluoric acid for 24 hours; and rinse the soaked ampoule with deionized water above 10 MΩ;

[0065] (1.3) Soak the quartz ampoule treated in step (1.2) with acetone for 24 hours; and ultrasonically clean the quartz ampoule after soaking in acetone for 3 hours (r...

Embodiment 2

[0074] Embodiment 2 is 12mm with diameter, and the preparation of the bromine-lead-cesium single crystal that length is 50mm is illustrated as an example;

[0075] In embodiment 2, adopt internal diameter to be the cylindrical quartz ampoule of 12mm, and one end thereof is the conical shape that taper angle is 20 °; The preparation process of bromine lead cesium single crystal among the embodiment 2 is set forth in detail below;

[0076] In embodiment 2, the cleaning of the quartz ampoule in step 1 and the process of coating the inner wall of the quartz ampoule in step 2 are the same as in embodiment 1;

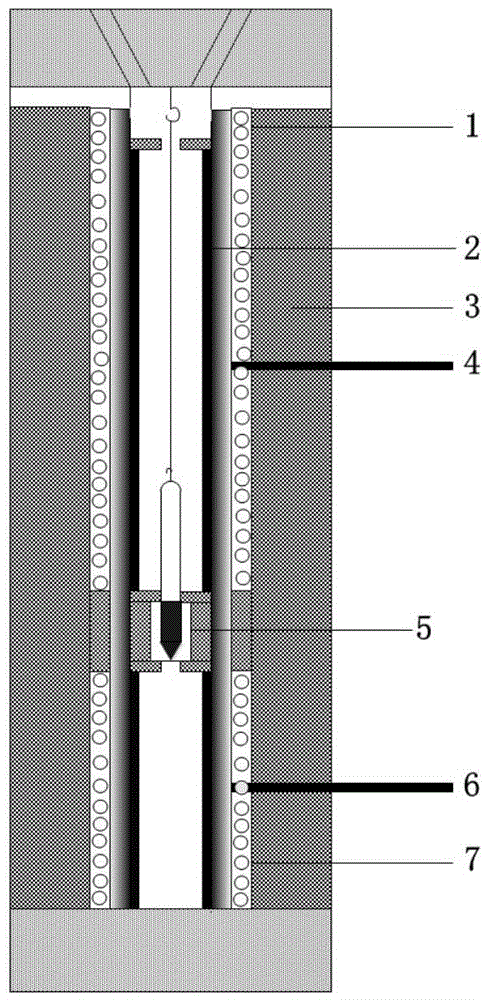

[0077] Step 3: Add 15.7gCsPbBr 3 Put the powder into a quartz ampoule, and vacuumize the quartz ampoule to 10 -3 pa and seal; the quartz ampoule is naturally vertically suspended in a dual temperature zone vertical tube furnace with a high temperature resistant wire, the conical tip of the quartz ampoule points to the bottom of the furnace, the conical tip of the ampoule is 20...

Embodiment 3

[0084] Embodiment 3 is illustrated with the preparation of the bromine-lead-cesium single crystal that is 15mm in length and 50mm in length;

[0085] In embodiment 3, adopt internal diameter to be the cylindrical quartz ampoule of 15mm, and one end thereof is the conical shape that taper angle is 20 °; The preparation process of bromine lead cesium single crystal among the embodiment 2 is set forth in detail below;

[0086] In embodiment 3, step 1 is the same as embodiment 1 to the clear and step 2 process of coating the inner wall of quartz ampoule to quartz ampoule;

[0087] Step 3: Add 30.0 g of CsPbBr 3 Put the powder into a quartz ampoule, and vacuumize the quartz ampoule to 10 -3 pa and seal; the quartz ampoule is naturally vertically suspended in a dual temperature zone vertical tube furnace with a high temperature resistant wire, the conical tip of the quartz ampoule points to the bottom of the furnace, the conical tip of the ampoule is 200mm from the bottom of the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com