Stannic oxide nanoparticles with high electrical property and preparation method therefor

A tin dioxide, electrical performance technology, applied in nanotechnology, circuits, electrical components, etc., can solve the problems of battery cycle performance and battery capacity that cannot meet the needs of industrial applications, cannot achieve industrial applications, and battery specific capacity decay, etc. Excellent charge-discharge cycle performance, excellent rate charge-discharge cycle performance, and good product batch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] More specifically, as an example, the preparation method of the present invention may include the following steps.

[0033] 1) Using tin salt as raw material, nano and micro particles soluble under alkaline conditions as template material, prepare a mixed solution of the two, wherein the concentration range of tin salt can be 0.1-5mmol / 40ml, and the concentration range of template material can be 0.1 ~ 5mmol / 40ml.

[0034] Where tin salts include but are not limited to crystalline tin tetrachloride (SnCl 4 ·5H 2 O), anhydrous tin tetrachloride, tin dichloride (SnCl 2 2H 2 O) or anhydrous tin dichloride etc., preferably SnCl 4 ·5H 2 O and SnCl4 .

[0035] Substances (template materials) of nano and micro particles soluble under alkaline conditions include but are not limited to silicon dioxide (SiO 2 ) and / or alumina (Al 2 o 3 ) particles, the particle size of which can be between 5nm and 50μm, and the structure includes various irregular solid particles and hol...

Embodiment 1

[0055] 1) With crystalline tin tetrachloride (SnCl 4 ·5H 2 O) is raw material, silicon dioxide nanotube (referring to patent for preparation method, application number: CN101280457A) is template material, prepares the mixed solution of both at room temperature, wherein the concentration of crystalline tin tetrachloride is 0.5mmol / 40ml, two The concentration of silicon oxide nanotubes is 1mmol / 40ml;

[0056] 2) Stir the mixed solution described in 1) at room temperature for 12 hours;

[0057] 3) The mixed solution in step 2) was centrifuged, and the obtained substance was dispersed in deionized water again, placed in a furnace, and heated at 450° C. for 7 hours;

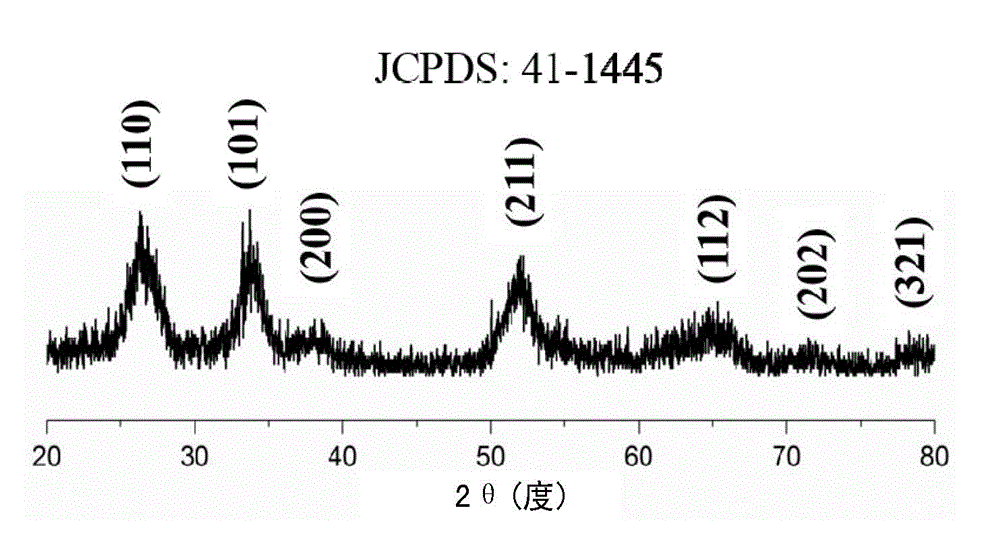

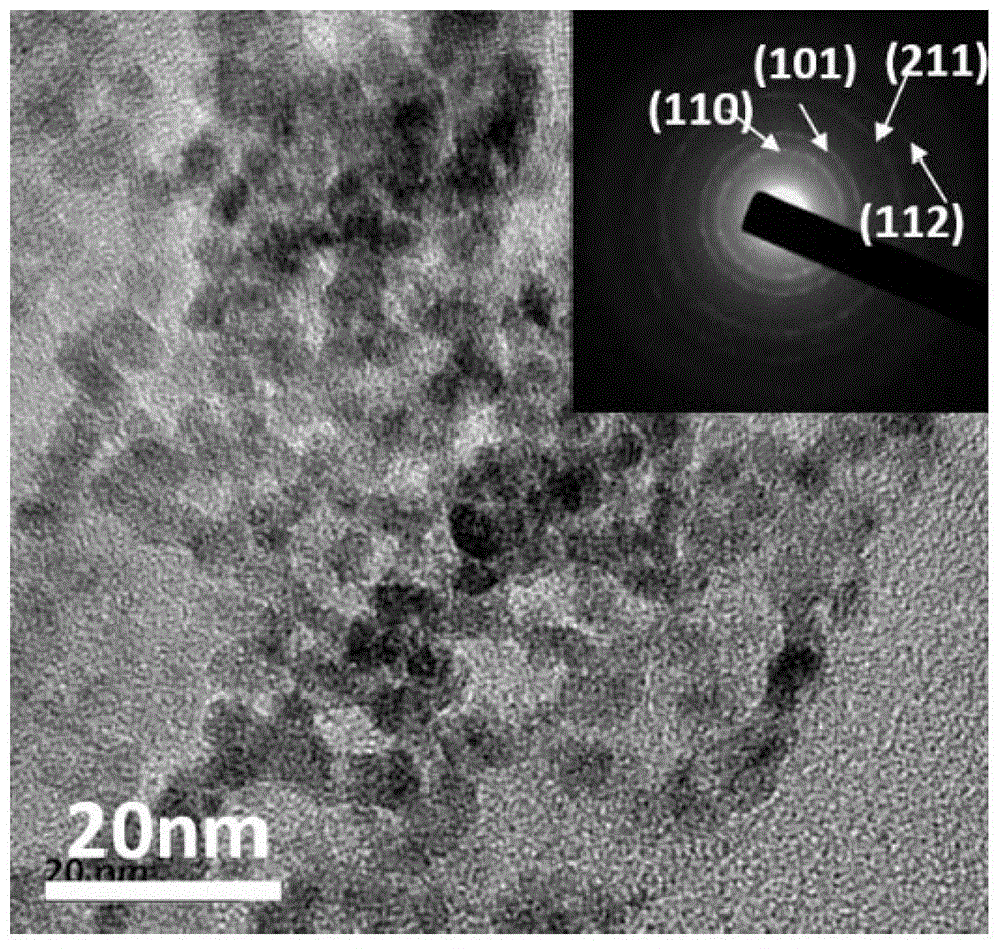

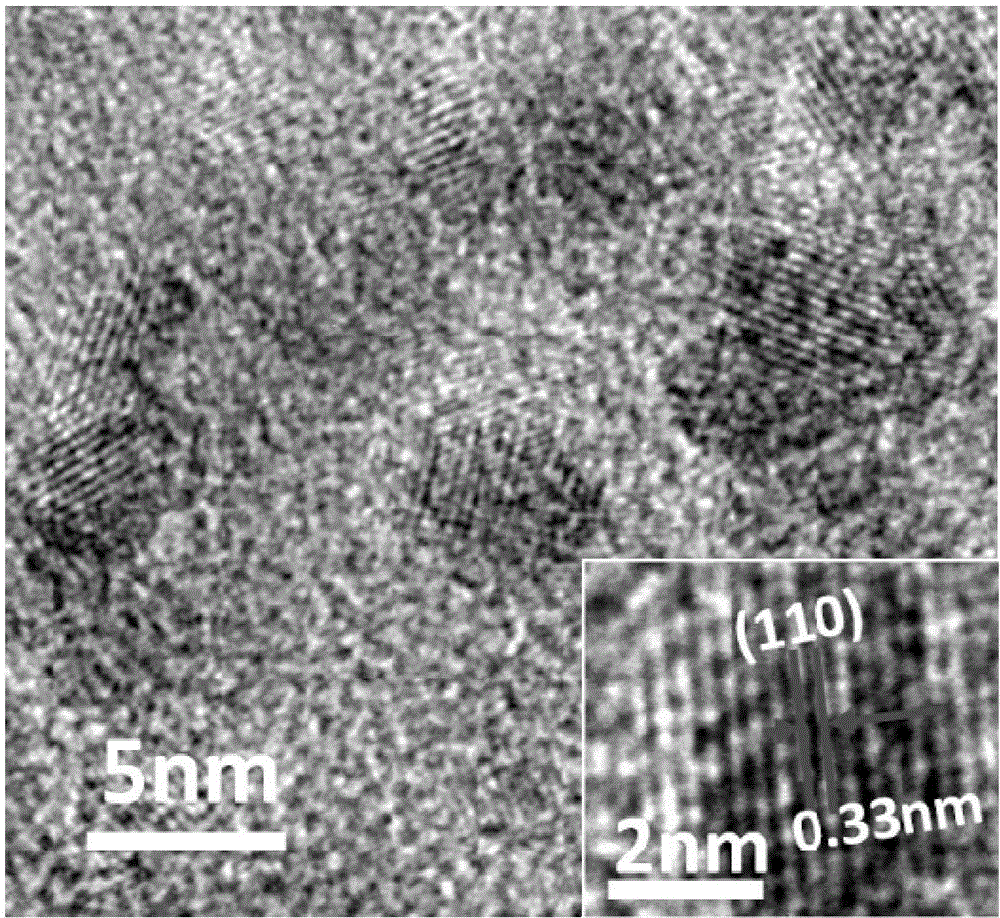

[0058] 4) Put the powder prepared in step 3) in 50 ml of NaOH solution with a concentration of 0.1 mol / L at a temperature of 50° C. and stir for 24 hours. After centrifugation, the samples were collected and dried in an oven at 70°C for 24 hours. Obtain tin dioxide nanoparticles. The SnO 2 Quantum dot size is 2-...

Embodiment 2

[0062] 1) Using anhydrous tin tetrachloride as raw material, silica hollow spheres (see patent for preparation method, application number: 201310190469.1) as template material, prepare a mixed solution of the two at room temperature, wherein the anhydrous tin tetrachloride The concentration is 1mmol / 40ml, and the concentration of silica nanotubes is 1mmol / 40ml;

[0063]2) Stir the mixed solution described in 1) at room temperature for 18 hours;

[0064] 3) The mixed solution in step 2) was centrifuged, and the obtained substance was dispersed in deionized water again, placed in a furnace, and heated at a temperature of 550° C. for 5 hours;

[0065] 4) Put the powder prepared in step 3) in 50 ml of NaOH solution with a concentration of 0.1 mol / L at a temperature of 50° C. and stir for 24 hours. After centrifugation, the samples were collected and dried in an oven at 70°C for 24 hours. Obtain tin dioxide nanoparticles. The SnO 2 Quantum dot size is 2-4nm, good dispersion;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Charge and discharge specific capacity | aaaaa | aaaaa |

| Charge and discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com