Process for producing n-propanol and propionic acid using metabolically engineered propionibacteria

A technology of propionic acid bacteria and n-propanol, applied in chemical instruments and methods, biochemical equipment and methods, oxidoreductases, etc., can solve the problem of lack of research on bacterial genetic engineering, difficulties in transforming gram-positive bacteria, and lack of cloning tools And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

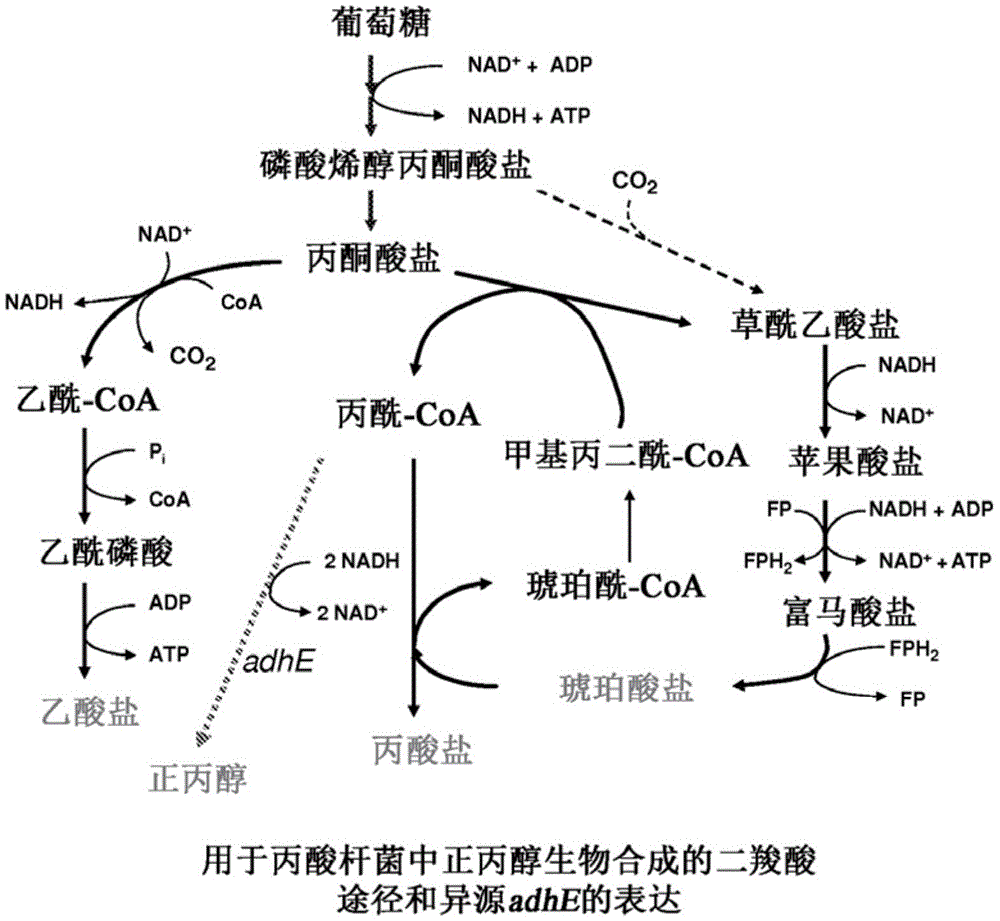

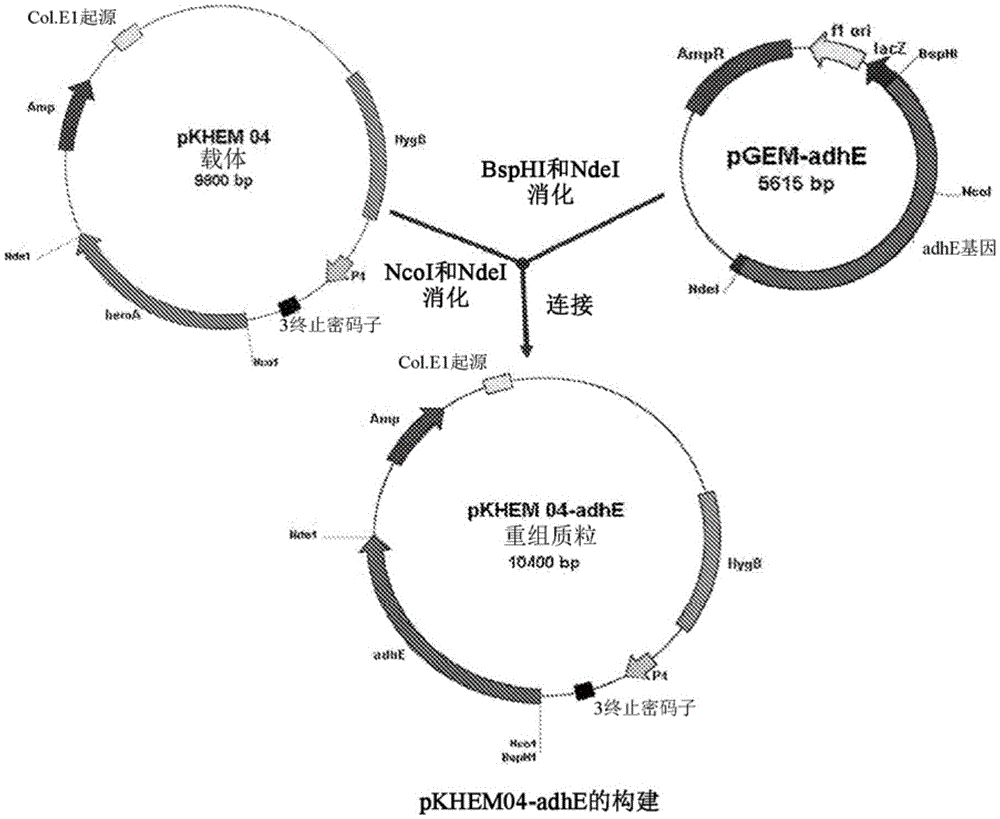

Method used

Image

Examples

example 1 and comparative example 1

[0043] Bacterial Strains, Plasmids, and Media:

[0044] All bacterial strains and plasmids used in this example are listed in Table 1. coli DH5α (a A facultative anaerobic organism with a GC content of 40% or higher) to obtain transformants thereof. For comparative purposes, Clostridium acetobutylicum (Clostridium acetobutylicum, C. acetobutylicum) American Type Culture Collection (American Type Culture Collection, ATCC) 824 (which is also a facultative anaerobic organism) was grown at 37°C in an enhanced Clostridium medium (RCM, Difco). Propionibacterium was grown anaerobically in Northern Lights BioScience (NLB) medium containing 10g / L sodium lactate, 10g / L yeast extract, and 10g / L tryptic casein soybean culture medium at 32°C to prepare Competent cells and for recovery of cells after electroporation. For fermentation kinetics studies, cells were cultured in the presence of 10 g / L yeast extract, 5 g / L tryptic casein, 0.25 g / L K 2 HPO 4 , 0.05g / LMnSO 4 , 25g / L glucose ...

example 2 and comparative example 2

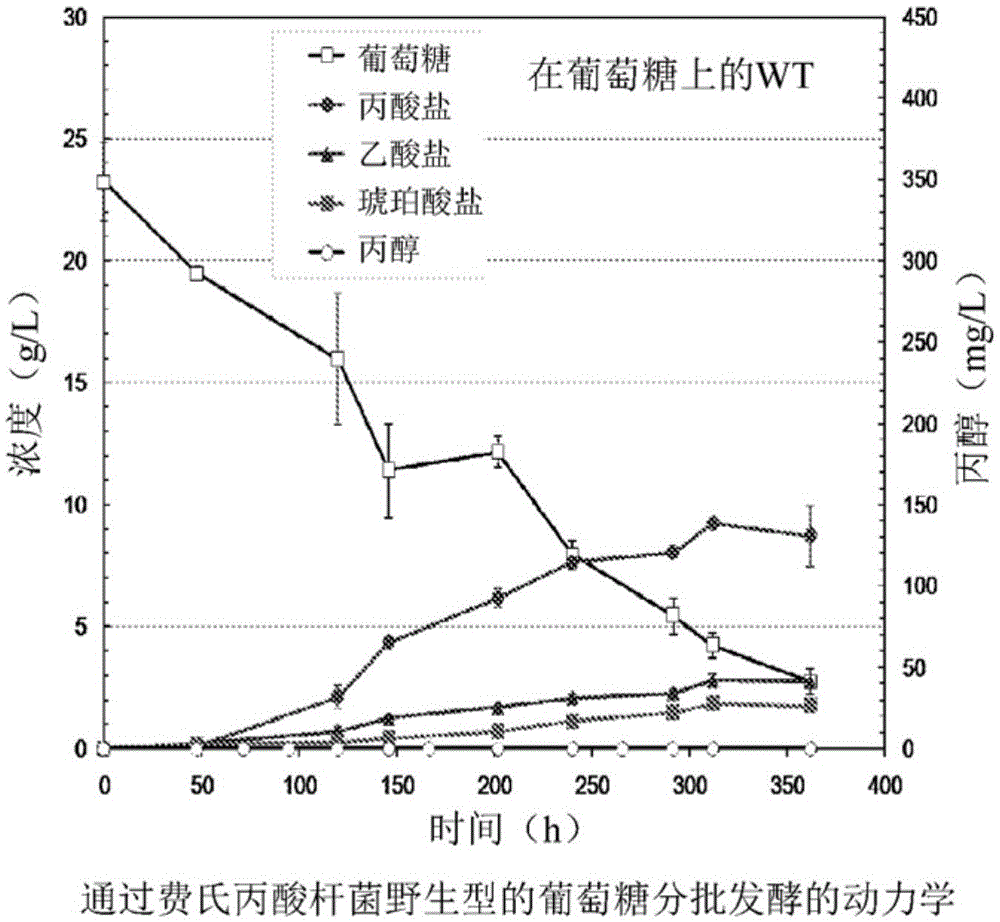

[0064] Kinetics of Batch Fermentation Using Glycerol as Substrate

[0065] Batch fermentation kinetics of various strains were also investigated with glycerol as carbon source and the results are shown in Figure 6 , Figure 7 as well as Figure 8 , the key kinetic parameters are summarized in Table 2. Again, the mutant produced significant amounts of n-propanol, while the WT did not produce any detectable amount. Compared to glucose fermentation, 50% to 65% more n-propanol was produced from glycerol at a faster rate, reaching a maximum propanol titer of approximately 500 mg / L at the end of the fermentation. It is particularly noteworthy that the mutant was able to use glycerol much faster and more efficiently, consuming all 20 g / L of glycerol in 200 h (consumption rate: roughly 0.10 g / L h), while WT used only Approximately 10 g / L glycerin (consumption rate: approximately 0.032 g / L·h). Thus, more propionate was produced by the mutant with a higher productivity of 0.047 g / ...

example 3 and comparative example 3

[0069] The effect of propanol on propionic acid fermentation:

[0070] Propionibacterium fresnerei DSM4209 wild-type cells were grown in culture medium with glycerol as carbon source and various amounts of n-propanol (0 g / L, 0.5 g / L, 1 g / L, 5 g / L and 10g / L) to illustrate the effect of n-propanol on cell growth and fermentation. as in Figure 9 , Figure 10 as well as Figure 11 As can be seen in , propanol does not significantly affect cell growth or fermentation at low concentrations of 0.1 g / L to 1 g / L, but inhibits cell growth with a significantly longer lag period at higher concentrations of 10 g / L. However, in the presence of 5 g / L propanol, cells were able to consume glycerol and produce propionate at a significantly higher rate after a short-term adaptation in the stasis phase. Specific growth rate, glycerol consumption rate, and propionate production rate and yield were estimated from the time course data and summarized in Table 4. The results showed that in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com