Saline-alkali soil improving method adopting chitosan soil deep scarification agent

A technology of soil deep loosening and soil improvement, which is applied in the field of chitosan soil subsoiling agent and saline-alkali soil improvement using chitosan soil subsoiling agent, which can solve the problem of small soil water holding capacity, large soil capacity, and lowering of pH value To improve soil structure, increase soil fertility, and reduce soil pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

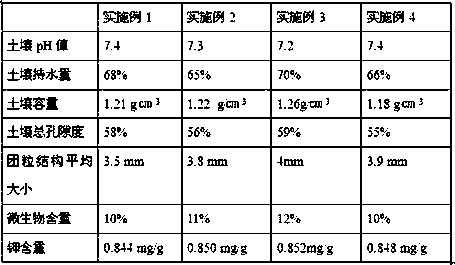

Examples

Embodiment 1

[0026] Embodiment 1 a kind of chitosan soil loosening agent

[0027] The weight ratio of each component of the soil subsoiling agent is:

[0028] 15 parts of chitosan, 5 parts of magnesium silicate, 10 parts of weathered coal, 8 parts of montmorillonite, 15 parts of Bacillus circulans bacteria liquid, 8 parts of oyster shell powder, 5 parts of ammonium persulfate, 7 parts of hydrolyzed polyacrylonitrile , 1 part of carboxymethyl cellulose, 3 parts of salicylic acid.

[0029] Preparation:

[0030] Step 1. Weigh each component of the soil subsoiling agent according to the above weight ratio, and set aside;

[0031] Step 2, pulverize weathered coal, montmorillonite, and oyster shell powder respectively, pass through an 80-mesh sieve, and add to the reaction kettle;

[0032] Step 3. Add magnesium silicate and ammonium persulfate into the reaction kettle, start stirring at a stirring speed of 120 rpm, and stir for 20 minutes to obtain a mixed solid powder;

[0033] Step 4, prep...

Embodiment 2

[0036] Embodiment 2 A kind of chitosan soil loosening agent

[0037] The weight ratio of each component of the soil subsoiling agent is:

[0038] 15 parts of chitosan, 8 parts of magnesium silicate, 15 parts of weathered coal, 10 parts of montmorillonite, 16 parts of Bacillus circulans bacteria liquid, 9 parts of oyster shell powder, 5 parts of ammonium persulfate, 13 parts of hydrolyzed polyacrylonitrile , 4 parts of carboxymethyl cellulose, 3 parts of salicylic acid.

[0039] Preparation method: same as the preparation method of Example 1.

Embodiment 3

[0040] Embodiment 3 a kind of chitosan soil loosening agent

[0041] The weight ratio of each component of the soil subsoiling agent is:

[0042] 16 parts of chitosan, 7 parts of magnesium silicate, 12 parts of weathered coal, 9 parts of montmorillonite, 16 parts of Bacillus circulans bacteria liquid, 8 parts of oyster shell powder, 6 parts of ammonium persulfate, 11 parts of hydrolyzed polyacrylonitrile , 3 parts of carboxymethyl cellulose, 4 parts of salicylic acid.

[0043] Preparation method: same as the preparation method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com