Carbon fiber shell and surface coating preparation method thereof

A surface coating and carbon fiber technology, applied in the direction of coating, etc., can solve the problems of insufficient surface interface adhesion, lower appearance quality of the product shell, uneven paint spraying film thickness, etc., to improve adhesion strength, three-dimensional appearance pattern color effect , The effect of reducing personnel investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

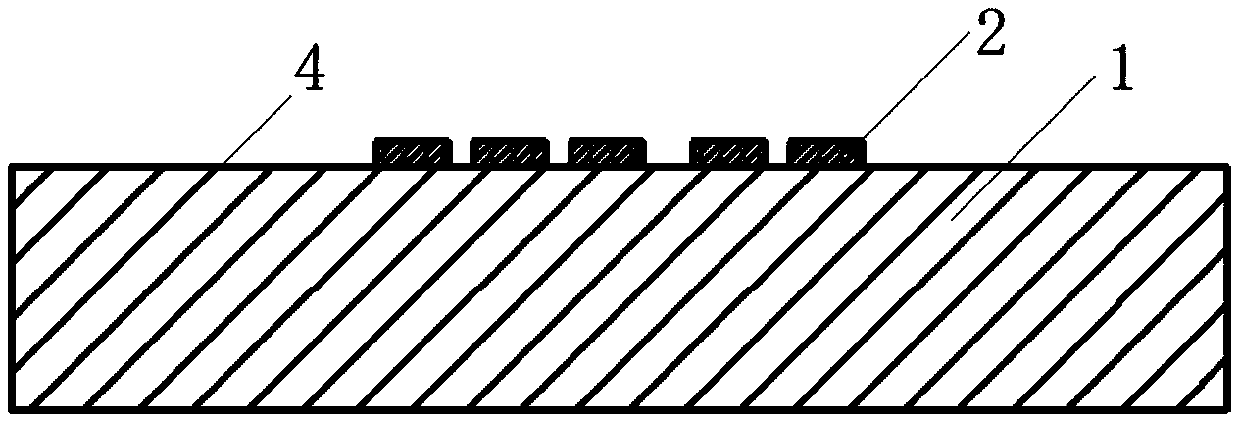

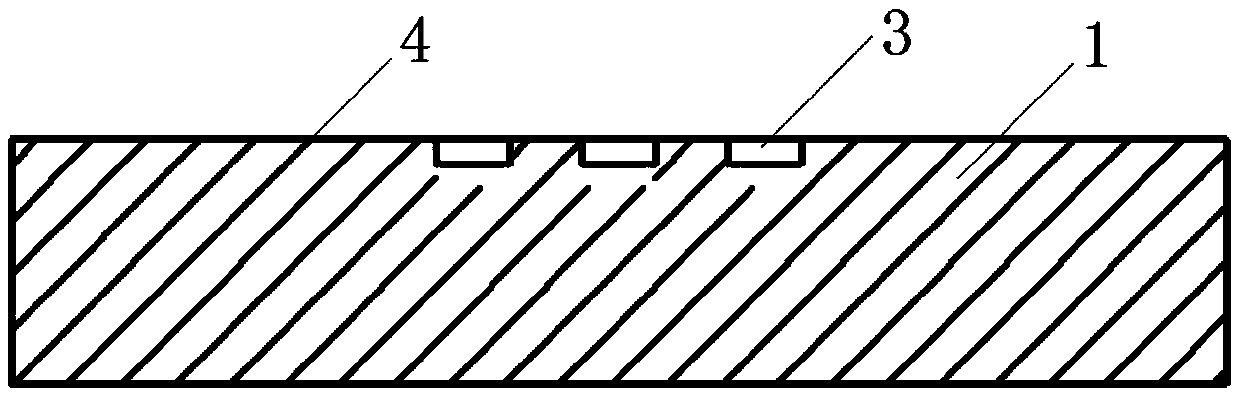

[0027] refer to Figure 1 to Figure 4 , in one embodiment, a carbon fiber shell surface coating preparation method, comprising the following steps:

[0028] S1. Prepare a carbon fiber sheet 1, the surface 4 of the carbon fiber sheet 1 has a concave pattern 3 and / or a convex pattern 2, these patterns 2, 3 can be various fonts or text or graphic logos, etc.;

[0029] S2, performing surface corrosion treatment on the surface 4 of the carbon fiber sheet 1 with a corrosive treatment solution to improve the adhesion of the surface of the carbon fiber sheet 1 to the coating to be coated;

[0030] S3. Put the carbon fiber sheet 1 that has undergone surface corrosion treatment into an injection mold, pour paint into the injection mold, and integrally form a surface coating 5 on the surface 4 of the carbon fiber sheet 1 .

[0031] In a preferred embodiment, in step S1, the patterns 2 and 3 are obtained by performing thermocompression molding and / or CNC processing on the carbon fiber sh...

example

[0047] The carbon fiber is made of Japanese TORAY3K carbon fiber woven prepreg, cutting machine, hot press forming machine, CNC engraving machine, ultrasonic cleaning machine, sodium hydroxide solution, nitric acid solution, acetone (analytical pure), Bayer's coating reaction casting film forming machine , PU thermosetting coatings.

[0048] Carbon fiber sheet 1 preparation

[0049] Cut the existing Japanese TORAY3K carbon fiber prepreg cloth into 155*120mm, and interleave the carbon fiber cloth according to the requirements. ~10min, pressure 10~30kg, vacuum <1*10^-6MP. Then put the pre-pressed carbon fiber sheet 1 into the forming mold, and then close the mold and heat and solidify. The curing temperature is 135-150° C. and the pressure is 40-60 kg. Solidify for 10-15 minutes, cool the mold to room temperature, take out the product inside the mold to get the rough carbon fiber sheet; then put the rough carbon fiber sheet on the CNC fixture and fix the milling LOGO font, acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com