Preparation method of fluorescent transparent ceramic disk for LED (Light-emitting Diode)

A technology of transparent ceramics and ceramic flakes, which is applied in the direction of circuits, semiconductor devices, electrical components, etc., to achieve the effects of high sample quality, simple process, and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the preparation method of the present invention, the ceramic flake green body is subjected to a firing process and annealing treatment to obtain the fluorescent transparent ceramic flake. Specifically, firing can be divided into two steps, pre-firing and vacuum sintering. The technical parameters of the pre-burning include heating at a rate of 1-5° C. / minute to 600-1200° C. and keeping the temperature for 2-12 hours. The process parameters of the vacuum sintering include a heating rate of 1-5° C. / min, heating up to 1700-1900° C., and holding the temperature for 3-24 hours. The technological parameters of the annealing treatment include a heating rate of 1-5° C. / min, heating up to 1300-1600° C., and holding the temperature for 3-48 hours.

[0047] The present invention adopts one-time molding gel injection molding technology and a two-layer board combined mold to prepare a fluorescent transparent ceramic sheet for LED with controllable thickness. More specifically, ...

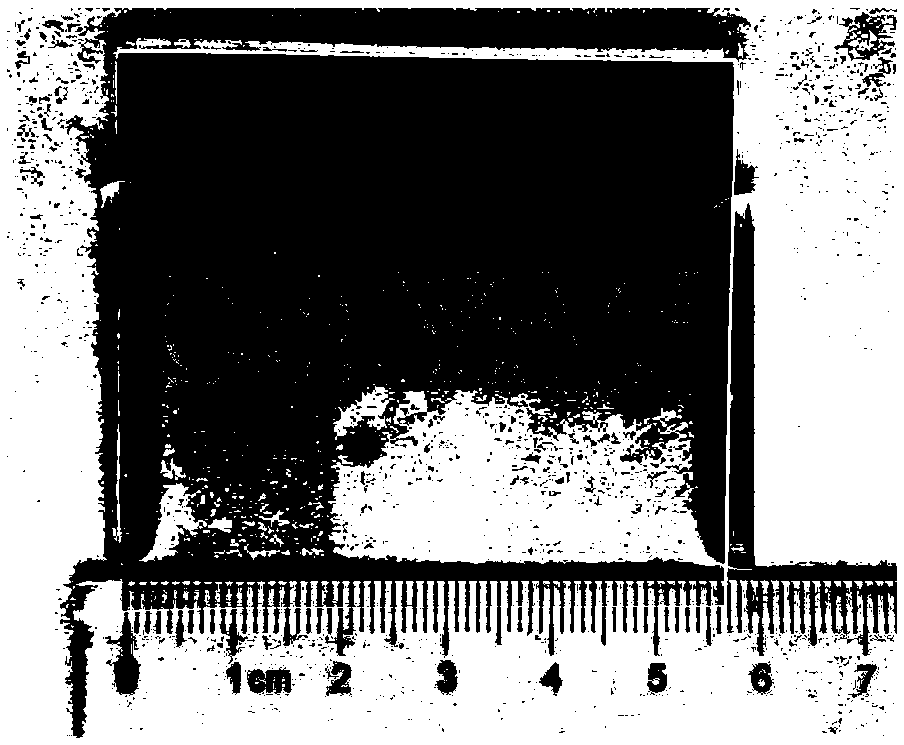

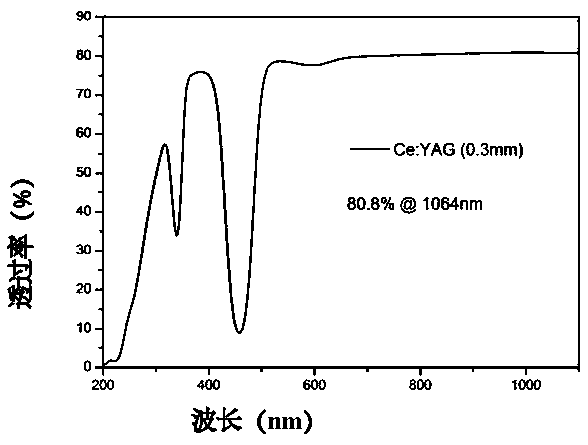

Embodiment 1

[0053] Weigh commercially available 65.54g high-purity Y 2 o 3 Powder, 3.44g high-purity CeO 2 Powder, 51gAl 2 o 3Put the powder and 0.15g sintering aid tetraethyl orthosilicate into a ball mill tank, add 50g deionized water and 1g dispersant ammonium polyacrylate, mix and ball mill for 1 hour to obtain a uniformly dispersed slurry, and then add 2.5g water-soluble ring Oxygen resin sorbitol glycidyl ether and 2.5 g of curing agent dipropylene triamine were ball milled for 0.5 hour and 1 hour respectively to obtain a water-based slurry with good fluidity and low viscosity. Inject the water-based slurry into the combination mold. The material of the two-layer mold is glass, and the thickness of the gasket is 0.5mm. Let it stand at room temperature and air environment, and fully solidify in situ for 3 hours to obtain a ceramic green body; the green body after demoulding The body was dried in an oven at 60°C for 12 hours, and then moved to an oven at 110°C for 12 hours to form...

Embodiment 2

[0056] Weigh commercially available 65.54g high-purity Y 2 o 3 Powder, 3.44g high-purity CeO 2 Powder, 51gAl 2 o 3 Put the powder and 0.15g sintering aid tetraethyl orthosilicate into a ball mill tank, add 50g deionized water and 1g dispersant sodium polyacrylate and mix ball mill for 1 hour to obtain a uniformly dispersed slurry, then add 2.5g water-soluble ring Oxygen resin sorbitol glycidyl ether and 2.5 g of curing agent dipropylene triamine were ball milled for 0.5 hour and 1 hour respectively to obtain a water-based slurry with good fluidity and low viscosity. Inject the water-based slurry into the combined mold. The material of the two-layer mold is glass, and the thickness of the gasket is 1.5mm. Let it stand at room temperature and air, and fully solidify in situ for 3 hours to obtain a ceramic body; the blank after demoulding The body was dried in an oven at 60°C for 24 hours, and then moved to an oven at 110°C for 24 hours to form a complete dry and uniform gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luminous flux | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com