Preparation method of human fibrinogen

A technology of human fibrinogen and raw materials, which is applied in the direction of preparation methods of fibrinogen and peptides, animal/human protein, etc., can solve the problems of complicated production process steps, product purity and biological activity are not very ideal, and improve the comprehensive Utilization ability, biological activity and high purity, and the effect of easier monitoring of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Cryoprecipitate was prepared from human plasma by cryogenic centrifugation.

[0028] a. Plasma melting

[0029] Plasma thawing should be carried out in a class 100,000 clean room. Water bath melting method. The water temperature of the water bath melting method should be controlled below 37°C.

[0031] Plasma merging should be carried out under a 100,000-level vent. Before merging, plasma bags should be sterilized, that is, soaked in 75% alcohol for more than three minutes, and the outside of the plasma bag should be wiped with clean gauze before merging. When merging plasma, attention should be paid to drip recovery.

[0032] c. Centrifugal separation of cryoprecipitate

[0033] Lower the temperature of the mixed plasma to below 0°C, and perform centrifugation at 3±1 L / unit / min, and control the outlet temperature at 0-4°C.

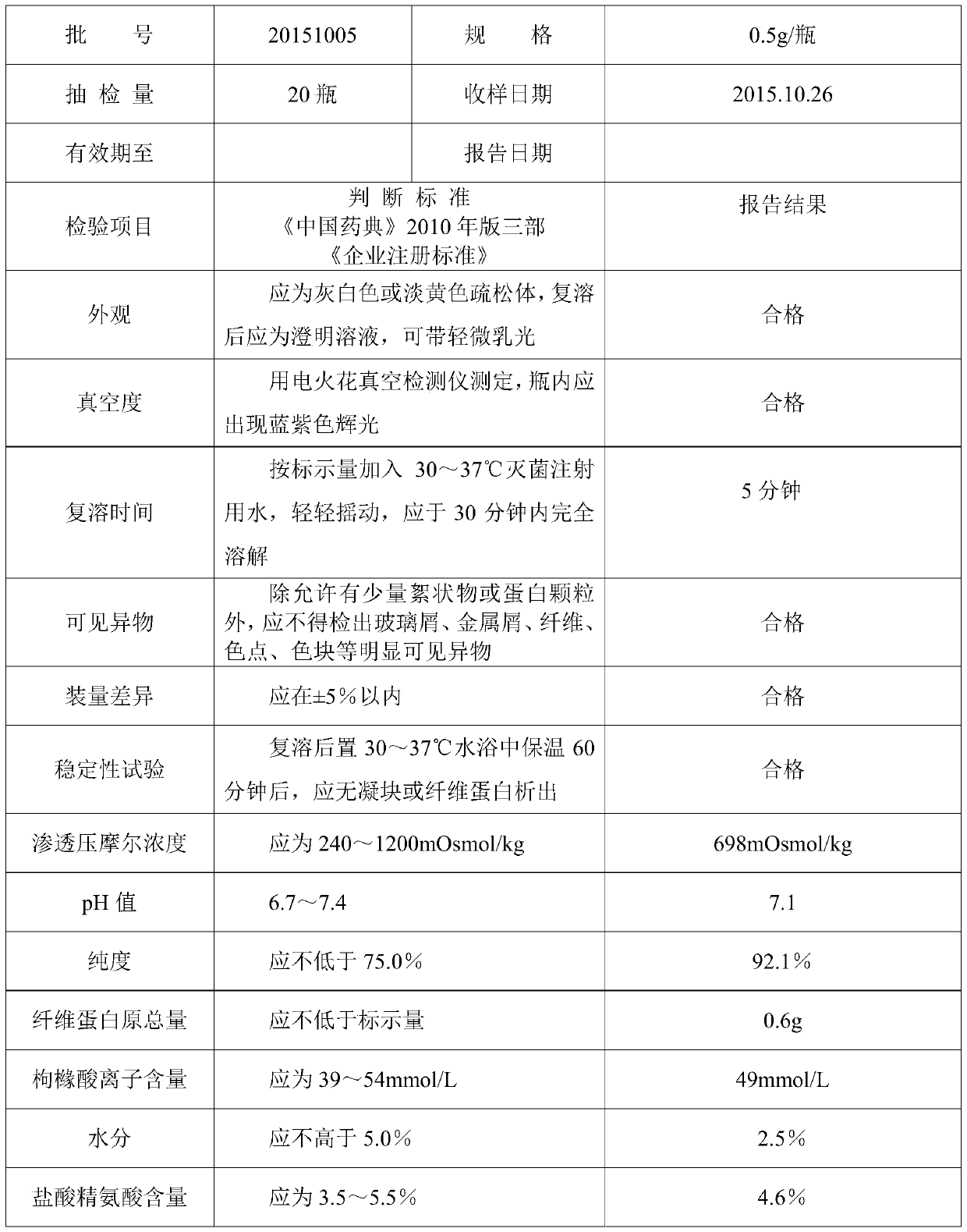

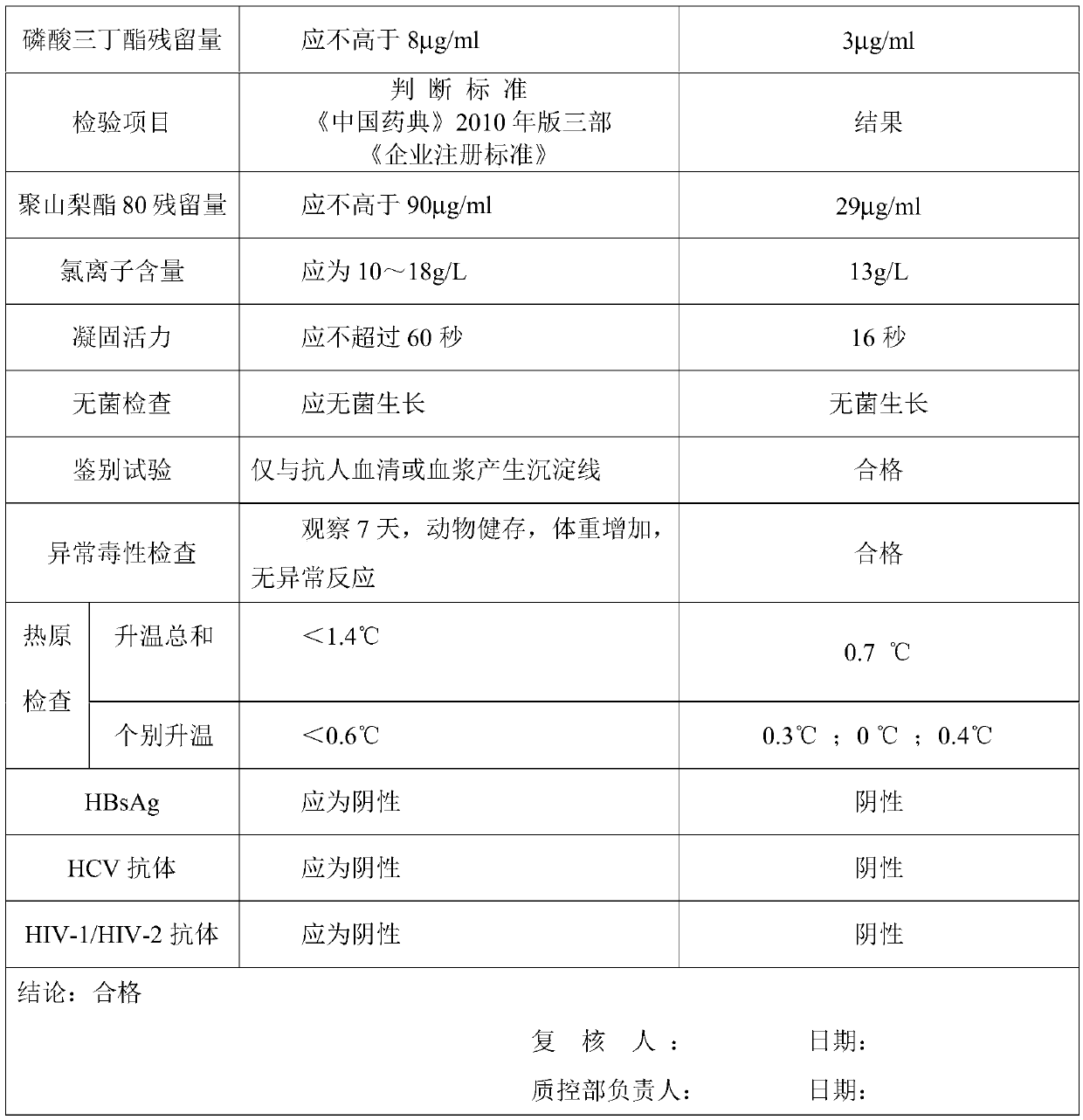

[0034] Attached to the quality standard of cryoprecipitated raw materials

[0035] 1. The raw material for cryop...

Embodiment 2

[0050] Process for extracting human fibrinogen from cryoprecipitate

[0051] (1) Dissolving the cryoprecipitate: Cut the freshly prepared cryoprecipitate into 1-3 cm blocks, and dissolve it with 3 times the volume of Tris-HCl solution with a concentration of 0.01-0.05mol / L at 24-26°C , adding heparin sodium solution to a final concentration of 0.005-0.065%, adding aluminum hydroxide gel suspension to a final concentration of 5%, stirring for 30 minutes and centrifuging to collect the supernatant.

[0052] (2) Clarification and filtration: perform clarification and filtration with a pretreated filter element with a pore size of 1 μm, and rinse the filter element with a balance solution to 4 times the volume of the cryoprecipitate.

[0053] (3) S / D inactivation: accurately measure the volume of the filtrate, slowly add the prepared S / D solution under stirring at a volume ratio of 1:10, so that the final concentration of polysorbate 80 in the protein solution is 1%, phosphoric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com