Anthraquinone functionalized polyvinylidene fluoride membrane as well as preparation method and application thereof

A polyvinylidene fluoride film and a polyvinylidene fluoride technology are applied in the field of anthraquinone-functionalized polyvinylidene fluoride film and its preparation, which can solve the problems of unachieved degradation of pollutants and harm to the environment, and achieve good application prospects, Beneficial for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

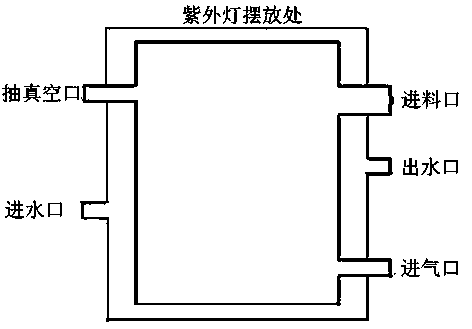

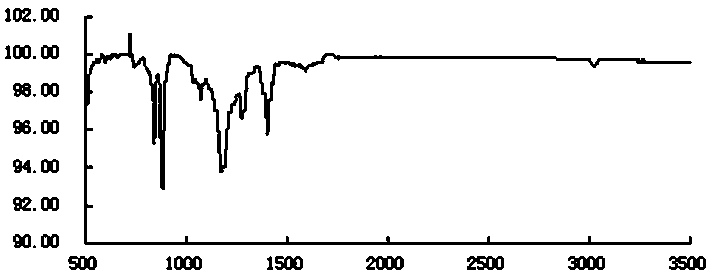

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of polyvinylidene fluoride membrane: Dissolve polyvinylidene fluoride and lithium chloride in N,N-dimethylformamide, stir and mix well to make a casting solution, in which N,N-dimethylformamide The dosage of formamide is 83wt%, the dosage of polyvinylidene fluoride is 15wt%, and the dosage of lithium chloride is 2wt%; then after defoaming in a vacuum constant temperature drying oven at 80°C for 48h, put it on a dry and clean glass plate Scrape to form a film, immediately place it in a coagulation bath composed of deionized water to form a film, and store the obtained film in deionized water;

[0028] 2) Membrane pretreatment: Soak the membrane prepared in step 1) in ethanol solution, ultrasonically clean for 30 minutes to remove impurities on the membrane surface, then soak in ultrapure water for 1 hour, and gradually replace the residual ethanol in the membrane. Then the membrane was dried at room temperature to constant weight, and stored with a sealing...

Embodiment 2

[0031] 1) Preparation of polyvinylidene fluoride film: Dissolve polyvinylidene fluoride and ethanol in N,N-dimethylacetamide, stir and mix well to make a casting solution, in which N,N-dimethylacetamide The amount of polyvinylidene fluoride is 84wt%, the amount of polyvinylidene fluoride is 15wt%, and the amount of ethanol is 1wt%. Then, after standing in a vacuum constant temperature drying oven at 80°C for 48 hours, scrape it on a dry and clean glass plate to form a film , immediately placed in a coagulation bath composed of deionized water to form a film, and the obtained film was preserved in deionized water;

[0032]2) Membrane pretreatment: Soak the membrane prepared in step 1) in ethanol solution, ultrasonically clean for 30 minutes to remove impurities on the membrane surface, then soak in ultrapure water for 1 hour, and gradually replace the residual ethanol in the membrane. Then the membrane was dried at room temperature to constant weight, and stored with a sealing ...

Embodiment 3

[0035] 1) Preparation of polyvinylidene fluoride membrane: Dissolve polyvinylidene fluoride and ethanol in dimethyl sulfoxide, stir and mix well to make a casting solution, wherein the amount of dimethyl sulfoxide is 88wt%, polyvinylidene fluoride The dosage of vinyl fluoride is 10wt%, and the dosage of ethanol is 2wt%. Then put it in a vacuum constant temperature drying oven at 80°C for 48 hours to defoam, scrape it on a dry and clean glass plate to form a film, and place it in deionized water immediately. The film is formed in the coagulation bath composed of the water, and the obtained film is preserved in deionized water;

[0036] 2) Membrane pretreatment: Soak the membrane prepared in step 1) in ethanol solution, ultrasonically clean for 30 minutes to remove impurities on the membrane surface, then soak in ultrapure water for 1 hour, and gradually replace the residual ethanol in the membrane. Then the membrane was dried at room temperature to constant weight, and stored w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com