Polyacrylamide coating agent for water-based drilling fluid, and preparation method thereof

A polyacrylamide and water-based drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as insufficient mud stability, excessive flocculation, difficult to dissolve clumps, etc., and achieve coating inhibition Excellent performance, easy industrialization, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

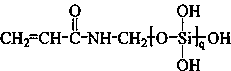

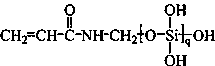

Embodiment 1

[0024] Add 60.00 g of the first monomer acrylamide, 35.00 g of the second monomer acryloyloxyethyl dimethyl benzyl ammonium chloride, 5.00 g of the third monomer (q=1), and 0.005 sodium persulfate into the reactor. g and 900.00 g of distilled water, mechanically stirred to dissolve completely; 0.005 g of sodium bisulfite was dissolved in 100.00 g of distilled water, and placed in a constant pressure dropping funnel; 30 minutes; then start to add sodium bisulfite aqueous solution dropwise, and the dropwise addition is completed within 15-25 minutes; keep the nitrogen atmosphere, stir and react at 10°C for 6 hours, discharge the material, and dry in a vacuum oven at 60°C After 24 hours, the low molecular weight cationic acrylamide coating agent was obtained after pulverization.

[0025] According to GB17514-1998, its molecular weight is 188.5×10 4 g / mol.

Embodiment 2

[0027] Add 382.50g of the first monomer sodium acrylate, 45.00g of the second monomer methacryloxyethyl dimethyl benzyl ammonium chloride, 22.50g of the third monomer (q=5), persulfuric acid into the reactor 0.90g of ammonium and 900.00g of distilled water, mechanically stirred to dissolve completely; 0.90g of pentaerythritol was dissolved in 100.00g of distilled water, and placed in a constant pressure dropping funnel; Minutes; then start to add pentaerythritol aqueous solution dropwise, and the dropwise addition is completed within 15-25 minutes; keep the nitrogen atmosphere, stir and react for 1 hour at 35°C, discharge the material, dry in a vacuum oven at 60°C for 24 hours, and pulverize Finally, a low molecular weight cationic acrylamide coating agent is obtained.

[0028] According to GB17514-1998, its molecular weight is 20.9×10 4 g / mol.

Embodiment 3

[0030] Add 240.00 g of the first monomer acrylamide, 58.50 g of the second monomer dimethyl diallyl ammonium chloride, 1.50 g of the third monomer (q=3), and 3.00 g of cumene hydroperoxide into the reactor g and 900.00g of distilled water, mechanically stirred to dissolve completely; 3.00g of ferrous chloride was dissolved in 100.00g of distilled water, and placed in a constant pressure dropping funnel; at 2°C, pass inert gas nitrogen into the aqueous solution to keep 40 minutes; then start to add ferrous chloride aqueous solution dropwise, and the dropwise addition is completed within 15-25 minutes; keep the nitrogen atmosphere, stir and react for 4 hours at 20°C, discharge the material, and dry it in a vacuum oven at 60°C After 24 hours, the low molecular weight cationic acrylamide coating agent was obtained after pulverization.

[0031] According to GB17514-1998, its molecular weight is 93.4×10 4 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com