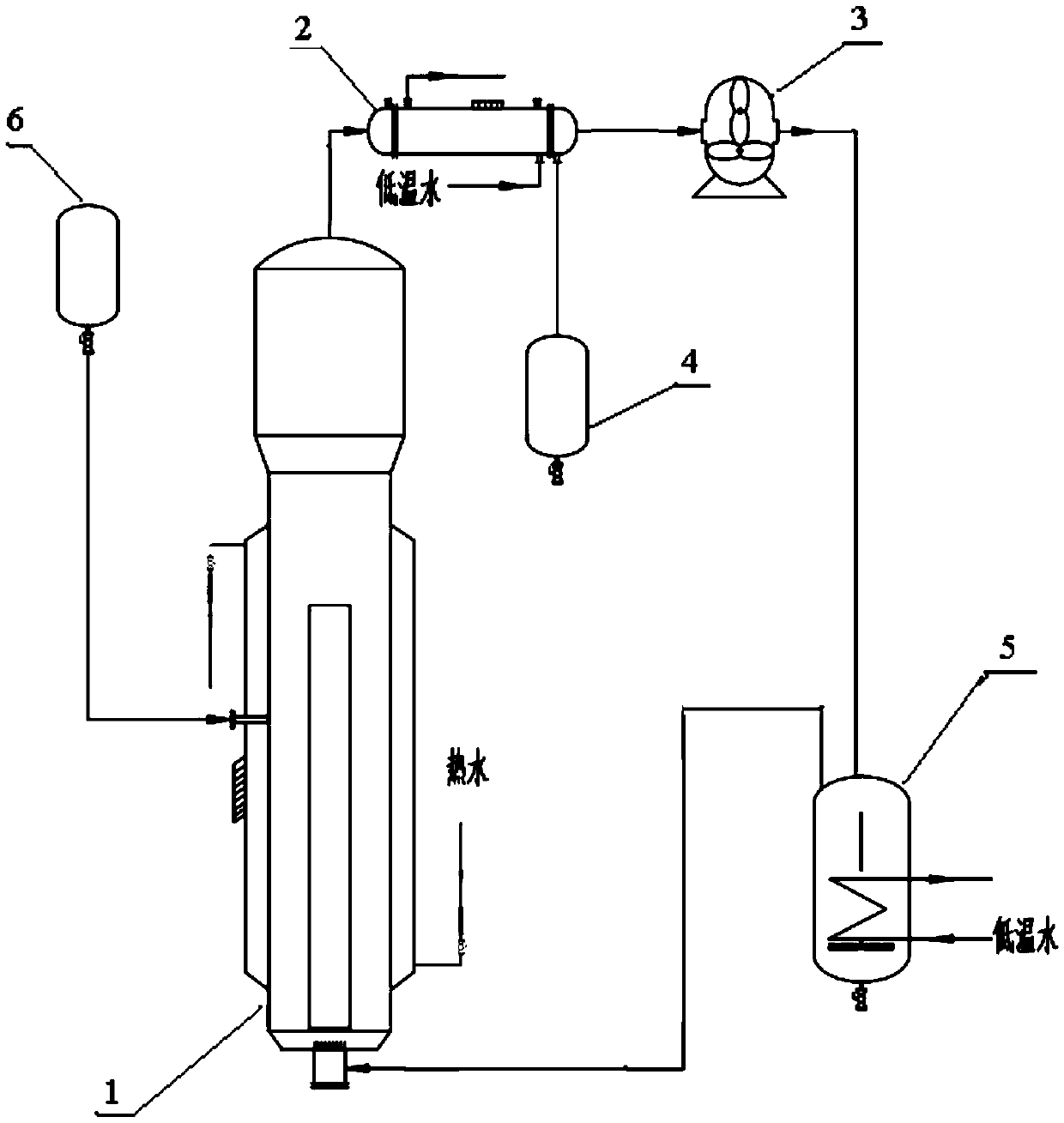

Method and system for enzymatic preparation of biodiesel

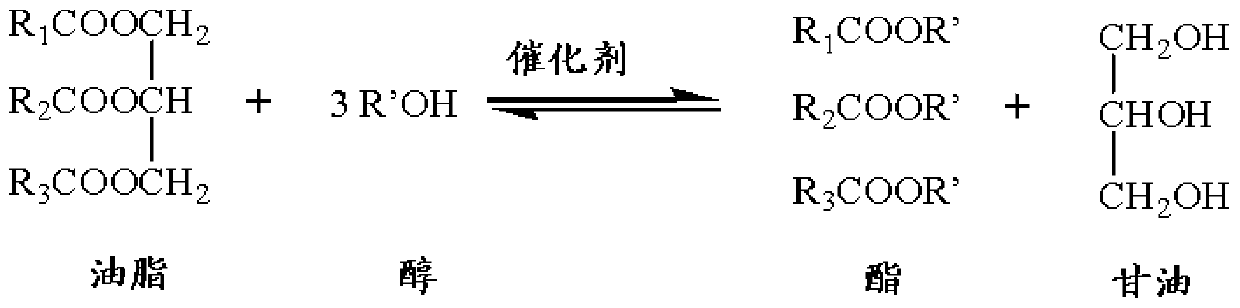

A technology for biodiesel and enzymatic preparation, which is applied in the fields of biofuel, petroleum industry, fatty acid esterification, etc., can solve the problems of increasing the amount of anhydrous short-chain alcohol, slowing down the production rate, and being unsatisfactory, and reducing the use of volume, the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Acid value 60~100mgKOH / g waste oil and phosphate aqueous solution (concentration is 0.075M, the mol ratio of sodium dihydrogen phosphate and disodium hydrogen phosphate is 1: 1) Place in the reactor, add liquid lipase derived from Aspergillus oryzae (Aspergillus oryzae) based on the amount of waste oil 1.5wt% to catalyze, carry out transesterification and esterification, the reaction temperature is 40 ° C, and continue to flow for 4 hours before the reaction Add 11wt% methanol based on the fat weight, react for 8 hours and then centrifuge to obtain the upper biodiesel crude ester (acid value 8.1mgKOH / g oil, water content 0.3wt%, methanol content 0.98wt%).

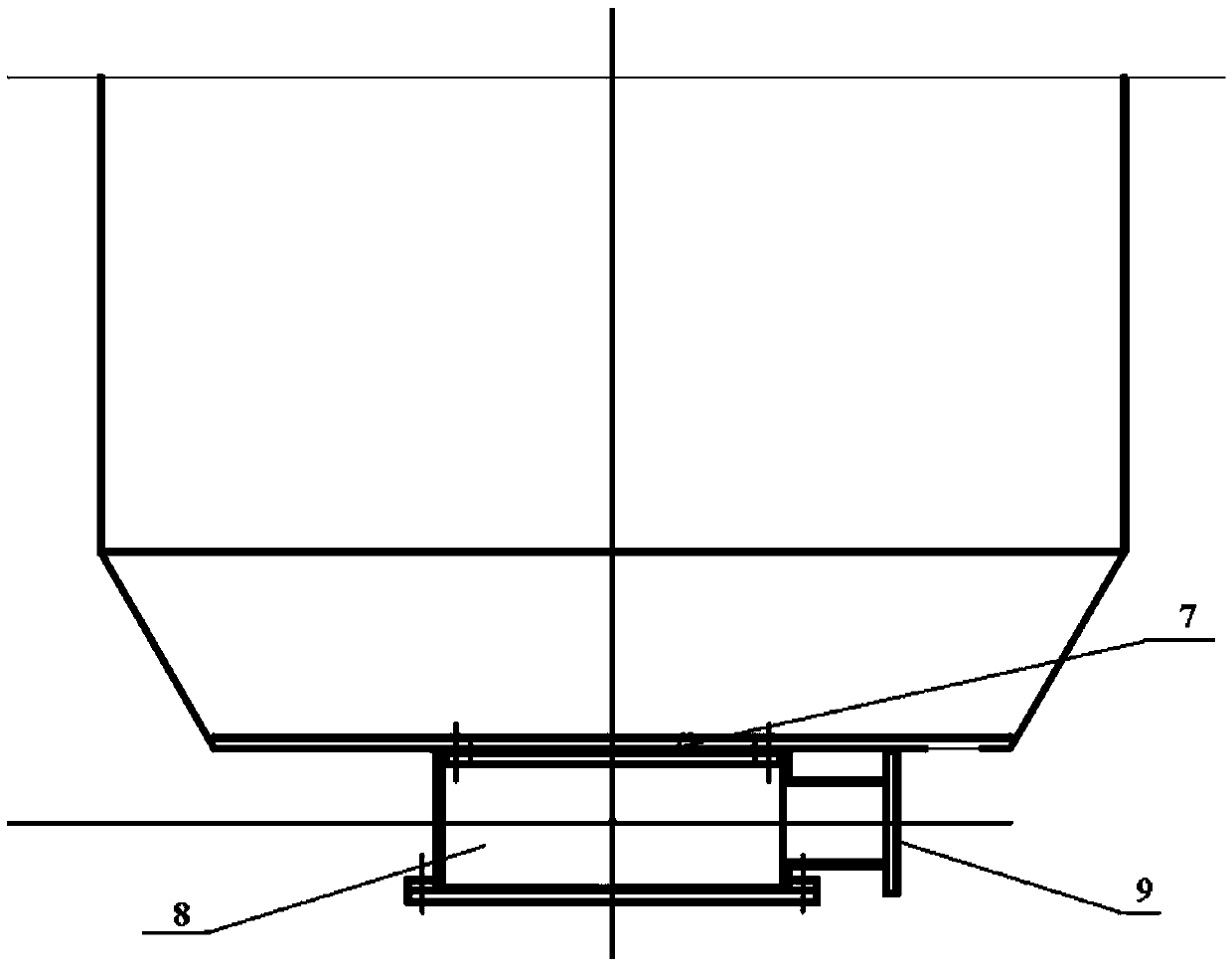

[0050] Take 10,000kg of the above biodiesel crude ester and place it in an airlift reactor for esterification reaction. The esterification reaction temperature is 40°C; the condensing temperature of the circulating gas condenser is 8°C, and the circulating gas volume is 20m 3 / min; the amount of water-absorbed methan...

Embodiment 2

[0053] Get 10000kg of crude biodiesel ester (acid value 8.1mgKOH / g oil, water content 0.3wt%, methanol content 0.98wt%) that is preliminarily prepared as in Example 1 and place it in an air-lift reactor, and the esterification reaction temperature is 35 ℃; the condensation temperature of the circulating gas condenser is 5 ℃, and the circulating gas volume is 20m 3 / min; the amount of water-absorbed methanol in the alcohol balance tank is 1786L (water content 0.5wt%), and the temperature is controlled at 15°C. The amount of immobilized lipase derived from Aspergillus oryzae was 1.5% based on the weight of crude ester. After reacting for 4 hours, 100 L of methanol (water content 0.5 wt%) was added to the reactor. After reacting for 6 hours, the acid value of the crude biodiesel ester decreased to 0.49mgKOH / g oil, the water content decreased to 220ppm, and the methanol content was 1.2wt%. The amount of hydrous methanol condensed by the circulating gas is 140L (methanol content ...

Embodiment 3

[0056] Get 10000kg of crude biodiesel ester (acid value 8.1mgKOH / g oil, water content 0.3wt%, methanol content 0.98wt%) that is preliminarily prepared as in Example 1 and place it in an air-lift reactor, and the esterification reaction temperature is 40 ℃; the condensing temperature of the circulating gas condenser is 5 ℃, and the circulating gas volume is 20m 3 / min; the amount of methanol absorbed in the alcohol balance tank is 1506L (water content 3.0wt%), and the temperature of the balance tank is controlled at 20°C. The amount of immobilized lipase derived from Aspergillus oryzae was 1.5% based on the weight of crude ester. After reacting for 4h, add methanol (water content 0.5wt%) 100L in the reactor; After reacting for 5h, the acid value of biodiesel crude ester is reduced to 0.44mgKOH / g oil, and water content is reduced to 254ppm, and methanol content is 1.1wt %. The amount of water-containing methanol condensed by the circulating gas condenser is 380L (methanol cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com