A high-efficiency xylose-fermenting mutant strain and a method for producing ethanol by fermentation thereof

A technology for ethanol production and mutant strains, which is applied in the field of high-solid lignocellulose ethanol fermentation, and can solve problems such as temperature tolerance that needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: U1-58 mutant strain mutagenesis screening

[0036] (1) Mutagenesis and primary screening S. passalidarum NRRL Y-27907 was used as the starting strain (hereinafter referred to as U1 strain), plasma mutagenesis was carried out for 25s, and the mutagenized bacterial solution was diluted to an appropriate concentration, and spread on the primary screening plate Above, after 1-2 days of inverted culture at 37°C, mutants with better growth and smooth surface were picked for re-screening.

[0037] Primary screening plate: xylose 50g / L, peptone 20g / L, yeast extract powder 10g / L, agar 20g / L, pH natural.

[0038] (2), double screening carries out xylose culture medium shake flask fermentation double screening to the mutant strain gained in (1), fermentation medium is: xylose 100g / L, yeast extract powder 22g / L, K 2 HPO 4 2.5g / L, MgSO 4 0.1g / L.

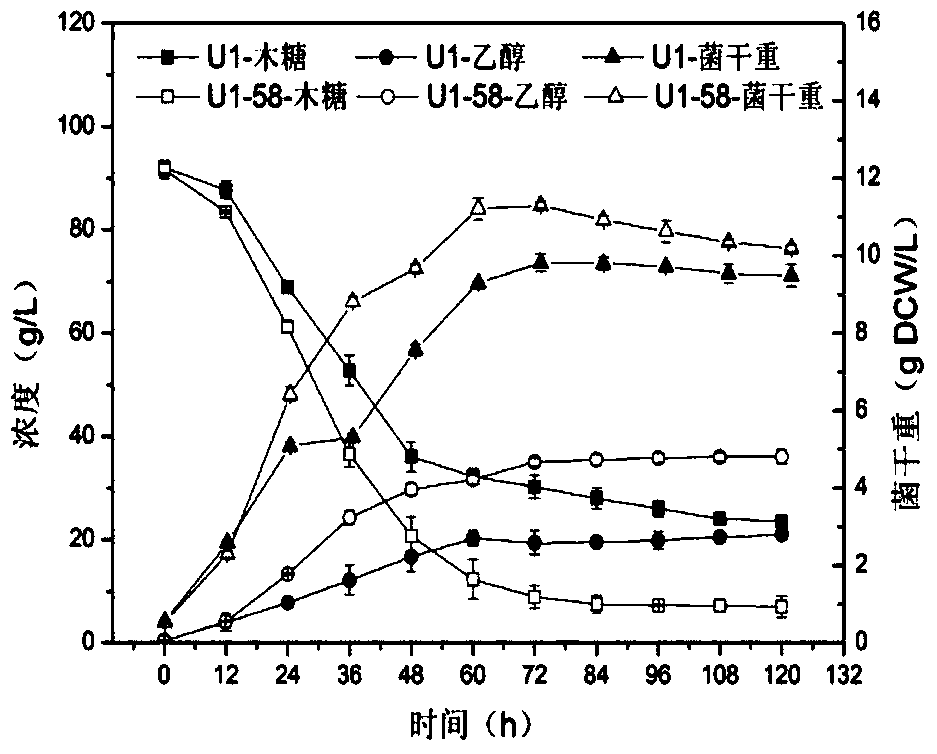

[0039] The fermentation conditions are: liquid volume 100mL / 250mL, strain initial OD 600 1.0, pH 5.5, temperature 3...

Embodiment 2

[0041] Example 2: Determination of the growth performance of the U1-58 mutant strain and the U1 starting strain at different temperatures

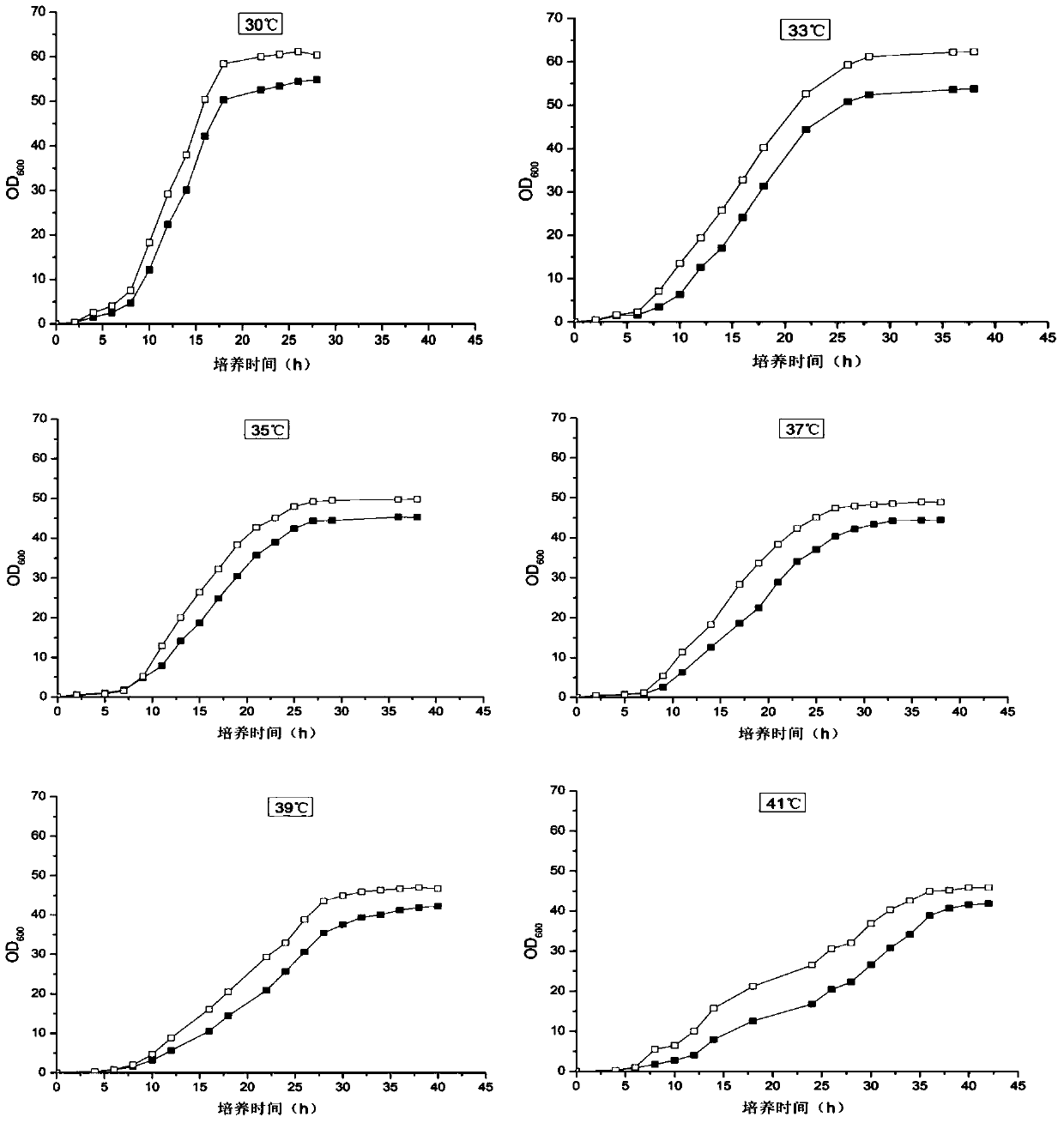

[0042] The U1-58 mutant strain and the U1 starting strain were used as mutual controls, and the growth curves of the strains were measured at 30°C, 33°C, 35°C, 37°C, 39°C and 41°C.

[0043] Determination method: Pick one ring of bacteria from the inclined plane and put it into a 250mL shaker flask filled with 50mL YPX liquid medium (20g / L xylose, 20g / L peptone, 10g / L yeast extract powder), at 30°C and 180rpm Cultivate, take samples at regular intervals, dilute appropriately, and measure the OD value at 600nm. Measurement results such as figure 2 shown.

[0044] from figure 2 It can be clearly seen that the temperature is between 30°C and 41°C. Although the growth of the strain is inhibited to varying degrees as the temperature increases, it can still be clearly seen that the growth performance of the U1-58 mutant strain is similar to ...

Embodiment 3

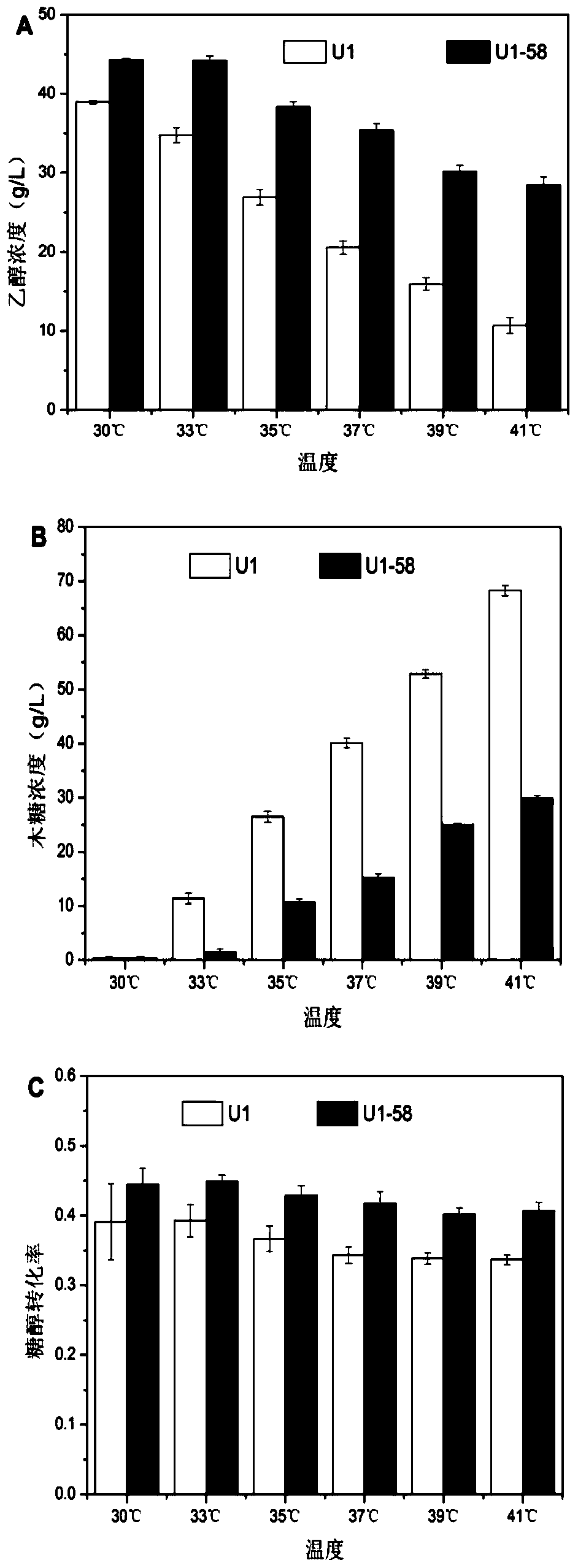

[0045] Example 3: Determination of xylose fermentation performance of U1-58 mutant strain at different temperatures

[0046] Using the U1-58 mutant strain and the U1 starting strain as mutual controls, the xylose fermentation performance of the strains was measured at 30°C, 33°C, 35°C, 37°C, 39°C and 41°C.

[0047] Fermentation condition and the mensuration of metabolite concentration in fermented liquid are all the same as embodiment 1 (2). The residual xylose concentration, ethanol concentration and corresponding sugar alcohol conversion rate in the fermented liquid after fermentation are analyzed as indicators, and the fermentation results are as follows: image 3 shown.

[0048] like image 3 As shown, at each temperature, the U1-58 mutant strain had a significantly higher ethanol concentration and a significantly lower residual sugar concentration than the U1 starting strain, and the corresponding sugar alcohol conversion rate also increased to a certain extent. At 30°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com