Patents

Literature

39results about How to "Strong storage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble fertilizer containing chitin and humic acid and production method thereof

InactiveCN101638333AHigh activityImprove fertilizer efficiencyFertilizer mixturesDiseaseContinuous cropping

The invention discloses a water-soluble fertilizer containing chitin and humic acid and a production method thereof. The method is characterized by degrading chitin, a natural high polymer, and then mixing chitin with humic acid solution and nitrogen fertilizer to produce the water-soluble fertilizer containing chitin and humic acid. The produced water-soluble fertilizer contains 20-40g / l of chitin, 20-40g / l of nitrogen, 170-190g / l of humic acid and 1-5g / l of plant growth regulators. The method is simple, easy to operate and high in feasibility of implementation. The produced water-soluble fertilizer integrates the functions of nutrition supplement, bacteria immunity and virus immunity, improves soil conditions, prevents hardening, raises ground temperature, promotes prematurity, resists diseases and tolerates stress, resists continuous cropping and balances nutrition, and features stable status and lasting fertilizer efficiency.

Owner:山东润华联邦农业科技有限公司

Breeding method of rice small grain sterile line, and simple seed production method of hybrid rice

ActiveCN106416997AHigh rate of outcrossingPromote germinationPlant genotype modificationAngiosperms/flowering plantsAgricultural scienceDisease rates

The invention discloses a breeding method of a rice small grain sterile line, and a simple seed production method of hybrid rice. The breeding method of the rice small grain sterile line comprises the following steps: hybridizing C815S used as a female parent and Qigui B used as a male parent to obtain hybrid F1, planting the F1, hybridizing the F1 and H15S used as a female parent to obtain hybrid F1', planting the F1' to obtain F2' generation, separating single plants with ideal plant type, high tillering ability, small height and small grain from F2' and F3' generations, and carrying out 2 or more generation of directional cultivation to obtain the rice small grain sterile line. The rice small grain sterile line cultivated by the breeding method of the sterile line has the advantages of high out-crossing setting rate, high germination vigor, high seedling rate, high storage resistance and low smut disease rate. Seeds are produced by adopting the rice small grain sterile line and a large grain restorer, the male parent and the female parent are simultaneously mixed and harvested, and sorting is carried out according to the grain thickness difference, so simple seed production of the hybrid rice is realized.

Owner:HUNAN HOPING SEEDS SCI & TECH INC

European pear can processing technology capable of preventing nutrient loss

The invention provides an european pear can processing technology capable of preventing the nutrient loss. The processing technology is characterized by comprising the following steps of 1) sorting, namely, sorting out raw materials based on a first-in and first-out principle according to different procurement times, varieties and places of origins; 2) spraying alkali and peeling, namely, arranging white peach which is divided into two halves and released from kernel in a single layer on a conveyor belt, wherein the kernel cavity is kept downward; 3) pre-boiling, namely, pre-boiling with a spiral pre-cooking machine, wherein the pre-cooking time is determined according to the technology requirement; 4) filling soup and sealing, namely, adding white granulated sugar to a pot; heating until slightly boiling; maintaining for 5 minutes; and uniformly agitating; and 5) sterilizing and cooling, namely, sterilizing at the high temperature through a continuous sterilizer. The european pear can processing technology has the beneficial effects that the peeling efficiency can be obviously improved after the treatment by adopting the technology, the peeling efficiency and the appearance quality can also be improved; in addition, the loss of sugar, protein, mineral substances, vitamin and other nutritional ingredients of an european pear can are obviously decreased, and thus the nutritional quality of the european pear can is improved, and the market competitiveness of the european pear can is enhanced. The european pear can is convenient to carry, high in storage resistance, and is a nutritional can with the market potential.

Owner:ZHONGDI FOODS

Safe production process for high-quality baked peanuts

Peanuts are an important industrial crop, an oil crop and an export-oriented crop in China, are a traditional food which is loved by Chinese people and rich in nutrient, and have the effects of tonifying spleen, harmonizing stomach, moistening lung for removing phlegm, tonifying deficiency, relieving a cough, nourishing to regulate the qi, clearing heat from throat, lubricating the intestines, promoting lactation and the like, and are also named as 'longevity nut'. The invention aims to provide a safe production process for high-quality baked peanuts. According to the safe production process, impurities in peanuts which serve as a raw material are removed, and fungi and bacteria possibly existing in the peanuts which serve as the raw material are killed. The safe production process mainly comprises three steps of removing impurities in the peanuts which serve as the raw material, continuously baking the peanuts through numerical control and sterilizing. By the safe production process, a baked pecan product can meet requirements of commercial sterilization, the shelf life of the product is prolonged, and the safety and market competitiveness of the product are improved; and the baked peanuts are convenient to carry, and high in keeping quality and are a nutritious food with market potential.

Owner:ZHONGDI FOODS

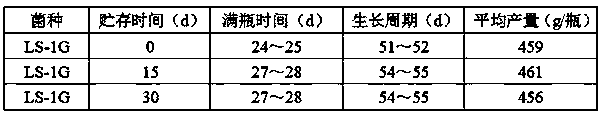

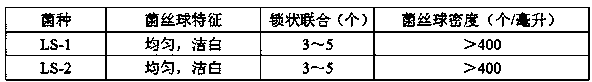

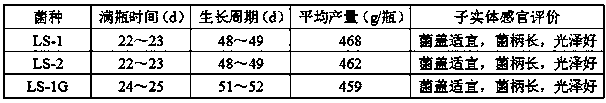

Needle mushroom liquid strain preparation method

InactiveCN108517303AMature technologyIncrease productionFungiMicroorganism based processesAdditive ingredientHypha

The invention discloses a needle mushroom liquid strain preparation method which comprises the following steps: taking needle mushroom mother strain, inoculating a PDA culture medium with the needle mushroom mother strain, choosing a strain block, inoculating a seed culture medium with the strain block and inoculating a pneumatic type fermentation tank with a seed solution by utilizing a soycomilfermentation medium or inoculating the pneumatic type fermentation tank with the seed solution by utilizing a compound nitrogen source fermentation medium to obtain the needle mushroom liquid strain.The needle mushroom liquid strain preparation method disclosed by the invention has the advantages of manure technology, large production, high automation degree and ability in saving labor sources and reducing production cost; a pollution rate is obviously reduced, a nutritional ingredient content in the fermentation medium is lower, and a culture temperature is also low; the liquid strain obtained under the conditions is more suitable for cultivation material environment, hypha restores more quickly after a cultivation material is inoculated, and strain culturing and mushroom producing timeis beneficial to be shortened.

Owner:HUAIHAI INST OF TECH +1

Processing technique of high-quality mango jam

InactiveCN104543641AImprove nutritional qualityReduce churnFood preparationAdditive ingredientNutritional quality

The invention relates to a processing technique of high-quality mango jam, which is characterized by comprising the following steps: 1) sorting mangoes; 2) spraying alkali and peeling the sorted mangoes; 3) precooking the peeled mangoes with steam; and 4) grinding the precooked mangoes into thick liquid, and seasoning the obtained product, wherein 0.5 percent citric acid is added 3 min before the end of concentration to prevent browning of the jam and loss of VC; and 5) performing sterilization and cooling, wherein sterilization is performed at high temperature, and cold water is used for cooling after sterilization, and the content of residual chlorine in the cold water is 0.5-0.6 mg / kg. The processing technique provided in the invention has the following benefits: with the adoption of the technique, the peeling efficiency can be significantly improved, the peeling effect and appearance quality are improved, loss of nutritional ingredients such as sugar, proteins, minerals, vitamins in the mango jam can be significantly reduced, the nutritional quality of the mango jam is increased, and the market competitiveness of the product is enhanced. The mango jam is convenient to carry, has high storage resistance, and is a nutritional product with market potential.

Owner:ZHONGDI FOODS

Making method of litchi and red date milk beverage

The invention relates to a making method of a litchi and red date milk beverage and belongs to the field of fruit juice processing. The beverage is prepared from, by weight, 10-40 parts of litchis, 50-80 parts of milk, 5-10 parts of red date juice, 1-5 parts of high fructose corn syrup, 1-5 parts of isomaltulose, 0.1-1 part of composite phosphate, 0.1-1 part of composite organic acid and 0.1-0.3 part of potassium sorbate. The making method comprises the steps that the litchis are graded, selected, cleaned, sterilized through dibromohydantoin, juiced and then evenly mixed with the milk; then, the mixed solution is mixed with mixed syrup prepared by the red date juice, high fructose corn syrup, isomaltulose, composite phosphate and composite organic acid; finally, ultra-high-pressure sterilization is adopted for obtaining a finished product. According to the making method, the nutrient components of fruits are reversed to a great degree, particularly amino acid and vitamins are reserved,the taste of fresh fruits is reserved, through scientific compatibility, the nutrients are comprehensive and balanced, and the beverage has the functions of replenishing qi, enriching the blood, calming the nerves, helping sleep, protecting skin, achieving beauty and the like and is unique in flavor, high in storage resistance, convenient to eat and good in sale prospect.

Owner:王慕贞

Agilawood pillow and manufacturing method thereof

InactiveCN109527905AImprove health care effectStrong storage resistancePillowsNervous disorderProduct processingAquilaria sinensis

The invention relates to an agilawood pillow and a manufacturing method thereof, and belongs to the field of agricultural product processing. The agilawood pillow is prepared from, by weight, 20-40 parts of agilawood leaves, 20-40 parts of agilawood blocks, 15-30 parts of aquilaria sinensis and 15-30 parts of semen cassiae. The manufacturing method of the agilawood pillow comprises the steps of washing clearly the picked agilawood leaves, agalloch, aquilaria sinensis and semen cassiae, afterwards, drying the materials, cutting the agalloch into small blocks, cutting the agilawood leaves and aquilaria sinensis into blades, manually removing impurities, conducting radiation sterilization, and afterwards, conducting packaging to finally manufacture a finished product of the agilawood pillow which has fragrant aroma and the functions of soothing the nerves and helping sleep. The agilawood pillow has good health-preserving and health-care effects, and can tonify qi and boost essence, and soothe the nerves and help sleep; moreover, the pillow is unique in fragrance, tolerant to storage and convenient to use and has a good sale prospect.

Owner:茂名市和香种植科技有限公司

Safe production process for peanuts with strawberry flavor

InactiveCN104544331AEasy to carryStrong storage resistanceFood preparationNumerical controlMetal impurities

The invention provides a safe production process for peanuts with a strawberry flavor. The process is characterized by comprising the following steps: 1) sorting; 2) removing metal impurities from the peanuts by using a metal detector; 3) adding a wrapping solution with seasonings to wrap the peanuts; 4) performing numerical control continuous baking; 5) performing infrared sterilizing; 6) removing peanuts with color aberration by using a color sorter; and 7) performing nitrogen-filled packing. The invention aims to remove impurities among the peanuts, kill possibly existing fungi and bacteria in the peanuts, and provide the safe production process for high quality peanuts with the strawberry flavor. The production process contains three major safe production steps including impurity removing, numerical control continuous baking and sterilizing and enabling the peanut products with the strawberry flavor to meet commercial sterilization requirements. Shelf life of the peanuts is prolonged. Product safety is improved and product market competitiveness is enhanced.

Owner:ZHONGDI FOODS

Additive for increasing intramural fat and improving flavor of beef

ActiveCN106721194AEnhance immune functionSpecific aromaFood processingAnimal feeding stuffFlavorMicroorganism

The invention discloses an additive for increasing intramural fat and improving flavor of beef. The additive consists of 90-95% by mass of a natural plant compound and 5-10% by mass of microorganism composite bacteria, wherein the natural plant compound comprises the following components in percentage by mass: 60-65% of perilla leaf powder, 20-30% of vetiveria zizanioides and 10-15% of rosemary powder; and 90 days before slaughtering of grown beef, the additive disclosed by the invention is added into feed, and the addition amount is 5-10% of the mass of basic daily feed. By adopting the green additive disclosed by the invention, the content of intramural fat of the beef can be remarkably increased, the content of unsaturated fatty acid and flavor amino acid of the beef can be remarkably increased, and the purposes of improving the meat quality and improving the flavor can be achieved.

Owner:贵州中科微农生物技术有限公司

Millet noodle and processing and manufacturing method of millet noodle

PendingCN110810723AAttractive colorMuscle smoothFood ingredient functionsBiotechnologyAnimal science

The invention relates to a millet noodle and a processing and manufacturing method of the millet noodle, and belongs to the technical field of noodle processing. The weight parts of components are 15-25 parts of millet, 60-100 parts of wheat flour, 2-4 parts of edible salt, 1-3 parts of guar gum, 0.5-1 part of vitamin C, and 20-35 parts of purified water. The manufacturing method is that: dry millets are cleaned, selected and crushed, and millet whole flour is obtained through a 100 mesh sieve; vitamin C, edible salt, guar gum and water are mixed uniformly according to the proportion to prepare a flour blending agent; wheat flour, the millet whole flour and the flour blending agent are put into a flour-mixing machine for dough kneading for 10-20 minutes, and thus a dough is prepared; the prepared dough is left to stand for 25-35 minutes; and the dough after standing is repeatedly rolled, the rolled dough is cut into strips, the strips are dried to a moisture content of 9-11%, the strips are cut into segments after dried, and the finished millet noodle product is obtained after weighing and packing. The millet noodle is supplemented with vitamin C which is lacking in ordinary noodles to the greatest extent; and after scientific compatibility, the nutrition is comprehensive and balanced, the taste is smooth, the gluten strength is high, the flavor is unique, the storability is high, the eating is convenient, and the sales prospect is good.

Owner:曾文标

Safe preparation technology of tomato-flavor cashew nuts

InactiveCN104413485AEasy to carryStrong storage resistanceFood preparationNumerical controlCooking & baking

The invention provides a safe preparation technology of tomato-flavor cashew nuts. The safe preparation technology is characterized by comprising the following steps: (1) removing impurities of a raw material, namely, removing the impurities such as mudstone, glass, and picking out mildewed and rotten grains mainly to avoid cross contamination of the raw material; (2) removing metal impurities possibly existing in the cashew nut raw material by a metal detector; (3) coating, namely, feeding a coating solution containing tomato seasoning into the cashew nut raw material, and carrying out coating treatment on the cashew nut raw material; (4) carrying out numerical control continuous baking, namely, working out the best condition of the tomato-flavor cashew nuts by repeated tests, and carrying out automatic production with programmed heating, wherein the baking temperature is 135-145 DEG C, and the baking time is 35-40 minutes; (5) sterilizing by infrared ray; (6) enabling products to evenly pass through a color selector to remove the mildewed and rotten grains; and (7) carrying out nitrogen-filled packing. The safe preparation technology of the tomato-flavor cashew nuts has the beneficial effects that after being treated by four main technologies including impurity removal, numerical control continuous baking, sterilizing by infrared ray and nitrogen-filled packing, the tomato-flavor cashew nut products reach the requirement of commercial sterility, so that the shelf lives of the products can be prolonged, and the safety of the products can be improved; furthermore, the tomato-flavor cashew nuts are convenient to carry and high in storability.

Owner:ZHONGDI FOODS

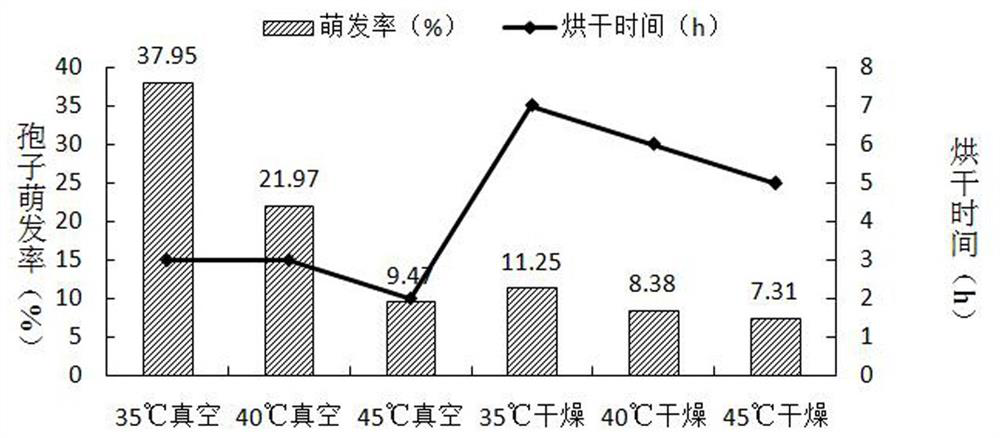

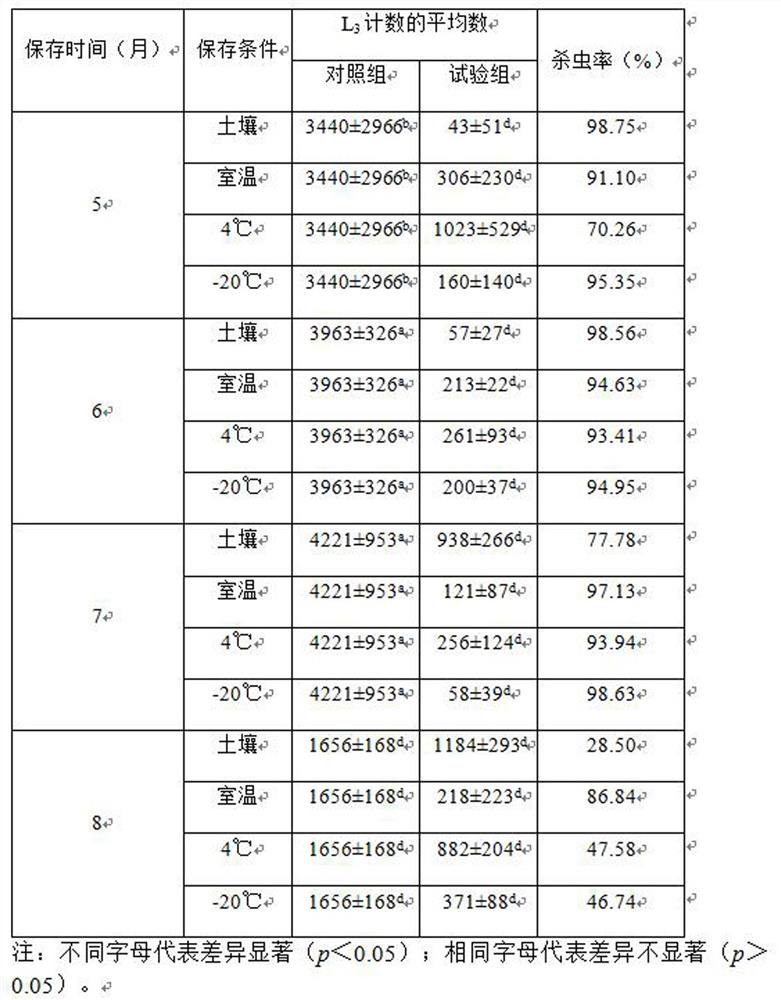

Preparation method and application of nematophagous fungus chlamydospore wettable powder

InactiveCN111700074AImprove insecticidal effectStrong storage resistanceBiocideMicroorganism based processesChlamydosporeDodecyl sulfate

The invention provides a preparation method and application of nematophagous fungus chlamydospore wettable powder. The wettable powder is characterized by comprising the following components in partsby weight: 15-20 parts of D. flagelans chlamydospore powder, 3-5 parts of sodium methylene dinaphthalene disulfonate, 3-5 parts of Chinese honeylocust fruit powder, 7-10 parts of sodium dodecyl sulfate and 60-70 parts of diatomite. The in-vitro insecticidal rate of the wettable powder on third-stage larvae of haemonchus contortus on sheep can reach 85.62%-89.77%.

Owner:潍坊中创生物科技有限公司

Processing preparation method of passionate passion fruit drink

The present invention relates to a processing preparation method of passionate passion fruit drink and belongs to the field of fruit juice processing. The passionate passion fruit drink comprises thefollowing components in parts by weight: 10-40 parts of passion fruits, 50-80 parts of Yakult, 5-10 parts of honey, 1-5 parts of high fructose corn syrup, 1-5 parts of isomaltulose, 0.1-1 part of compound phosphate, 0.1-1 part of compound organic acid, 20-50 parts of purified water and 0.1-0.3 part of potassium sorbate. The preparation method comprises the following steps: passion fruit classifying and selecting, washing, disinfecting with dibromohydantoin, blanching at 90-95 DEG C for 30 seconds, passion fruit peeling and fruit flesh digging out after the blanching, and evenly mixing with Yakult are conducted; then the passion fruits and Yakult are mixed with mixed syrup prepared from honey, high fructose corn syrup, isomaltulose, compound phosphate, compound organic acid and purified water; inspecting and sub-packaging to obtain a semi-finished product are conducted; and finally ultra-high pressure sterilization is conducted to obtain a finished product. The finally prepared finishedproduct of the passionate passion fruit drink is sour, sweet, tasty and unique in flavor. The passionate passion fruit drink retains the nutrient composition of the fruits to the greatest extent, especially amino acids and vitamins, retains the mouthfeel of the fresh fruits, is scientific in matching and comprehensive and balanced in nutrients, has effects on preventing fatigue, refreshing mind,dispelling alcoholism, protecting skin, nourishing skin, etc., and is also unique in flavor, strong in storage resistance, convenient to eat and excellent in sales prospects.

Owner:佛山市犇淼科技有限公司

Apple can processing technology capable of preventing nutrient loss

InactiveCN103651756AImprove nutritional qualityReduce churnFruits/vegetable preservation using sugarsBiotechnologyNutrition

The invention provides an apple can processing technology capable of preventing nutrient loss. The apple can processing technology is characterized by comprising the following steps of (1) sorting: sorting raw materials according to the purchase time, the varieties and the places of production in sequence of first in and first out; (2) alkaline leaching and peeling: arranging white peach slices subjected to half-opening and core removal on a conveyer belt by a single layer in the manner that core grooves are downward; (3) precooking: performing precooking through a helical precooker, wherein the precooking time is set according to a technical requirement; (4) filling and sealing: pouring white granulated sugar into a pot for heating to micro-boiling, retaining for 5 minutes, and uniformly stirring the materials; and (5) sterilization cooling: performing high-temperature sterilization through a continuous sterilization machine. The apple can processing technology capable of preventing the nutrient loss has the beneficial effects that the peeling efficiency can be obviously improved, and the peeling effect and the appearance quality are enhanced; furthermore, the loss of nutrients such as sugar, proteins, minerals and vitamins in apple cans is obviously alleviated; the nutrient quality of the apple cans is improved; the market competitiveness of products is improved. The apple cans are convenient to carry and high in storage resistant performance, and have market potential.

Owner:ZHONGDI FOODS

Safety production process for high-quality baked sunflower seeds

Owner:ZHONGDI FOODS

An additive for increasing intermuscular fat and flavor of beef

ActiveCN106721194BEnhance immune functionSpecific aromaFood processingAnimal feeding stuffBiotechnologyAmino acid content

The invention discloses an additive for increasing intermuscular fat and flavor of beef, which is composed of 90-95% by mass of natural plant complex and 5-10% by mass of microbial compound inoculant, wherein the composition of the natural plant complex And the mass percentage is 60-65% of perilla leaf powder, 20-30% of vetiver powder, and 10-15% of rosemary powder; 90 days before the fattening cattle are slaughtered, start adding and using the additive provided by the invention in the feed , the addition amount is 5-10% of the basic diet quality; using the green additive provided by the invention can significantly increase the intermuscular fat content of beef cattle, and can significantly increase the muscle unsaturated fatty acid content and flavor amino acid content, thereby improving meat quality and flavor. the goal of.

Owner:贵州中科微农生物技术有限公司

Litchi jelly and preparation method

InactiveCN110786487ARetained amino acidRetain vitaminsSugar food ingredientsNatural extract food ingredientsBiotechnologyFruit juice

The invention relates to a litchi jelly and a preparation method thereof, and belongs to the technical field of fruit juice processing. The litchi jelly comprises the following components in parts byweight: 20-40 parts of litchi pulp, 60-70 parts of a litchi juice, 7-10 parts of a natural pectin extract, 1-5 parts of fructooligosaccharide, 1-5 parts of isomaltulose, 0.2-0.3 part of citric acid, and 0.1-0.3 part of potassium sorbate. The preparation method comprises: sorting and selecting litchi, performing washing, performing peeling and pitting, performing blanching, performing juicing, performing cooking, performing packaging, and performing sterilization, and finally the ''Q-elasticity and smoothness and rich flavor'' litchi jelly product is prepared. The jelly can retain a variety ofnutritional ingredients such as amino acids and vitamins of litchi to the greatest extent, can maintain the taste of fresh litchi, and has unique flavor, strong storage resistance, convenient eating,and excellent sales prospects.

Owner:高州市大田顶农业发展有限公司

Safe production technique for manufacturing milk-flavor peanut

InactiveCN104544336AEasy to carryStrong storage resistanceFood preparationNumerical controlFood flavor

The present invention relates to a safe production technique for manufacturing milk-flavor peanut. The safe production technique is characterized in that it comprises the following steps: 1) raw material impurities removing; 2) carrying out metal detection by a metal detector; 3) coating; 4) carrying out the pecan nuts numerical control continuous baking; 5) carrying out infrared sterilization: infrared sterilization time is 3-6 seconds; 6) removing rotten fruit by a color selector; 7) nitrogen packaging: carrying out nitrogen automated packaging, controlling residual oxygen content below 2%. The safe production technique has the following beneficial effects: by four major process treatments of impurity removing, numerical control continuous baking, sterilization and nitrogen packaging, the milk-flavor peanut products can reach commercial sterility requirements, the shelf life of products can be extended, product security can be improved, and market competitiveness can be enhanced. The milk-flavor peanuts have characteristics of easy carrying and strong storage resistance, and are nutritional food with market potential.

Owner:ZHONGDI FOODS

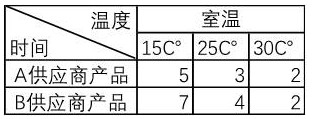

Red tassel sorghum seed initiation and backdrying method

ActiveCN114467408AIncrease productionThe uniformity of germination is improvedBiocidePlant growth regulatorsBrassicaBacillus thuringiensis

The invention discloses a red tassel sorghum seed drying initiation method which comprises the following steps: 1) soaking red tassel sorghum seeds in an initiator solution at the temperature of 15-25 DEG C for 12-48 hours; wherein the initiator solution is prepared from the following raw material components: 1g / L of bacillus polymyxa, 7.42 g / L of trichoderma harzianum, 4-6ml / L of bacillus thuringiensis, 0.5 g / L of borax and 0.5 ml / L of brassinolide; and 2) drying the seeds obtained in the step 1) until the water content is 7-15%. According to the priming and drying method for the red tassel sorghum seeds, through specific cooperation of priming and drying, the vigor of the seeds is enhanced, germination and seedling emergence of the red tassel sorghum seeds are promoted, and the yield and seedling emergence uniformity of the red tassel sorghum in the field are improved; the seed germination agent has the advantages of good stability and strong storage resistance, has very stable germination rate when stored under variable temperature and constant temperature conditions, keeps good seed viability after one year, and prolongs the storage period.

Owner:GUIZHOU UNIV +1

Safe production technology of high-quality baked peanuts in shell

The invention provides a safe production technology of high-quality baked peanuts in shell. The safe production technology is characterized by comprising following steps of: 1) removing impurities in raw materials; 2) passing through a metal detector; 3) wrapping; 4) baking continuously under numerical control; 5) sterilizing by infrared ray; 6) passing through a color selector; and 7) performing vacuum packaging. Beneficial effects of the production technology are that: by the three main processes of impurity removing, continuous baking under numerical control and sterilization, the baked peanut product can meet requirements of commercial sterilization, the shelf life of the product is prolonged, the safety of the product is enhanced and the market competitiveness of the product is enhanced. The baked peanuts in shell are convenient to carry, strong in storage resistance and are nutritious food with market potential.

Owner:ZHONGDI FOODS

Safe production technology for high-quality honey-roasted sunflower seeds

A safe production technology for high-quality honey-roasted sunflower seeds is characterized by comprising steps as follows: 1) impurity removal for raw materials; 2) application of a metal detector; 3) coating; 4) numerically-controlled continuous roasting; 5) infrared sterilization: infrared sterilization is conducted for 2-3 s; 6) application of a color sorter: mildewed and rotten fruits are removed by the aid of the color sorter; 7) nitrogen-charged packing: automatic nitrogen-charged packing is conducted, and the remaining oxygen amount is controlled to be smaller than 1.5%. The safe production technology has the benefits as follows: the honey-roasted sunflower seeds can meet the requirement of commercial sterilization through three steps of major technological treatment of impurity removal, numerically-controlled continuous roasting and sterilization, the shelf life of the sunflower seeds is prolonged, the safety of the sunflower seeds is improved, and the market competitiveness of the sunflower seeds is enhanced. The honey-roasted sunflower seeds are convenient to carry and high in storability and are nutritional food with the market potential.

Owner:ZHONGDI FOODS

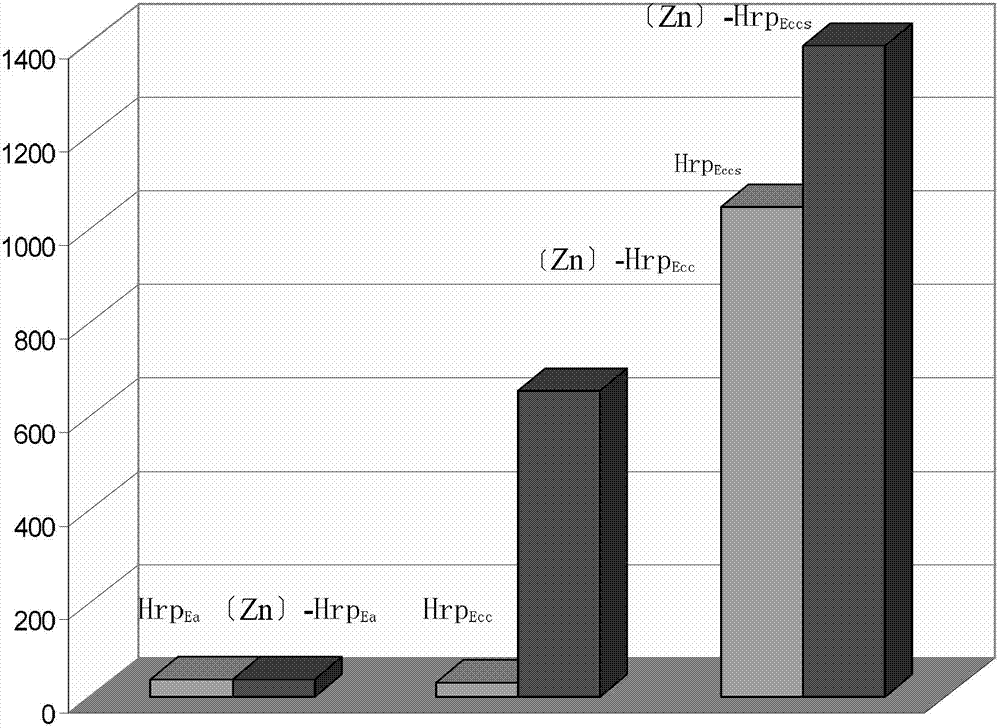

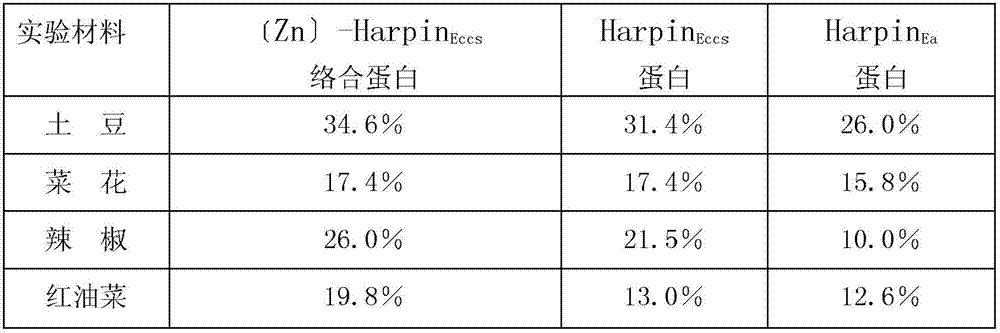

Complexing method and complexing product of Chinese cabbage soft-rot fungus HarpinEccs protein and zinc ions

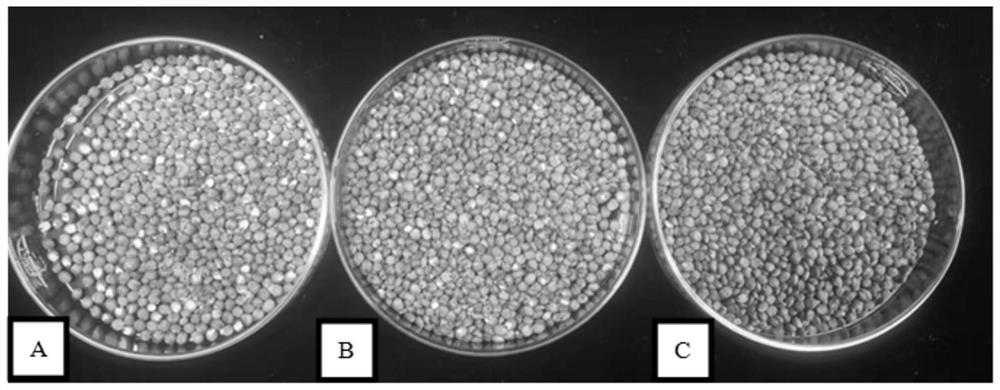

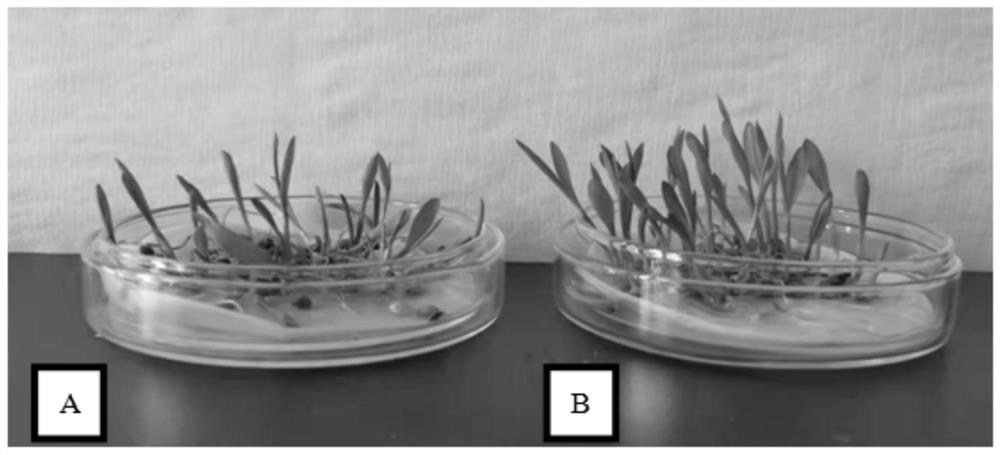

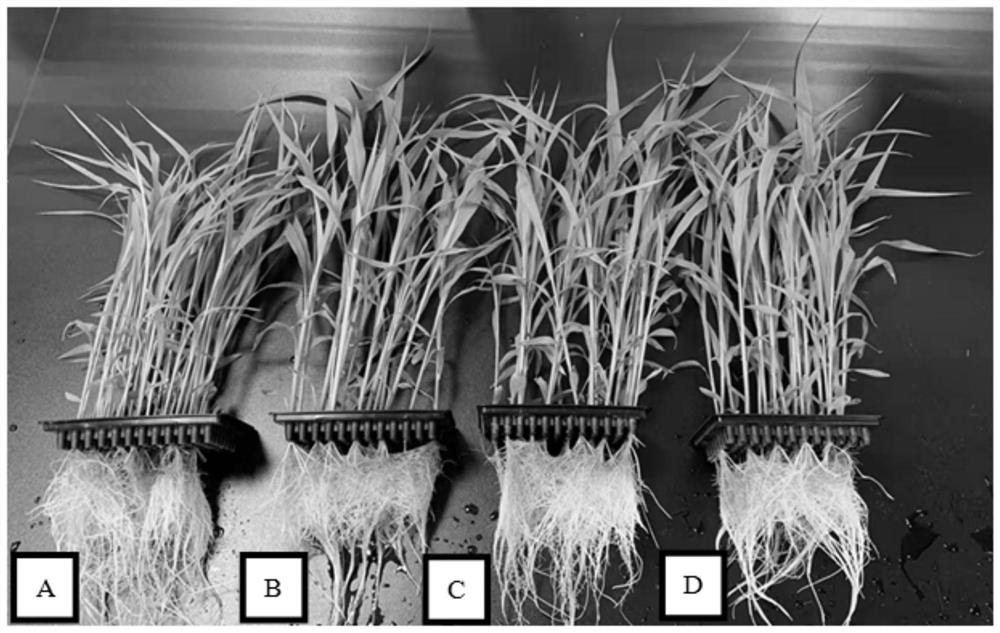

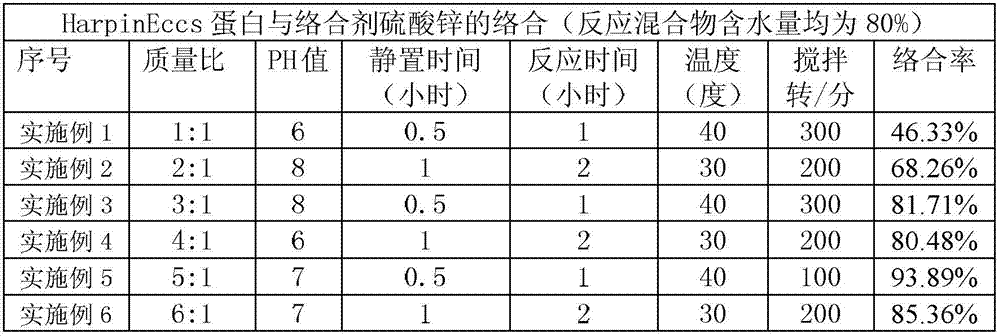

InactiveCN102775479AImprove stabilityStrong tolerance and storage resistancePlant growth regulatorsBiocideProtein proteinAllergic reaction

The invention discloses a complexing method and a complexing product of Chinese cabbage soft-rot fungus HarpinEccs protein and zinc ions. Original production fungus of the HarpinEccs protein is a carrot soft-rot Erwinia carotovaora subsp. carotovora Chinese cabbage soft-rot fungus variant CSDS001 strain; the amino acid sequence of the HarpinEccs protein is shown in SEQ ID.No1; preferable complexing conditions and using ranges are given. The complexing product shows higher stability, is stronger tolerance and storability on high temperature, illumination, acid and alkaline and can be used for inducing more types of test plants subjected to allergic reaction. With the function of inducing the test plants, the test plants generally show stronger disease resistance, stronger insect prevention and other stronger stress resistance, and the complex product has the promotion function of test plant growth and development.

Owner:吴伯骥

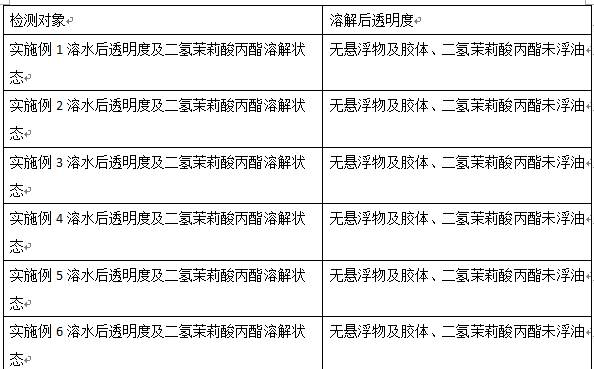

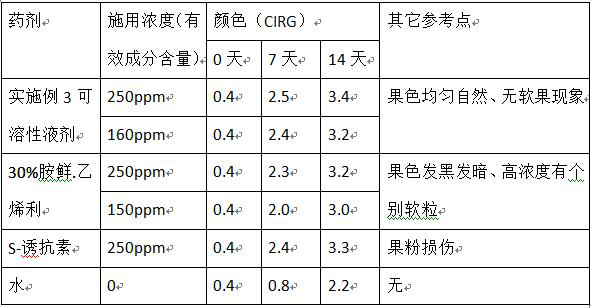

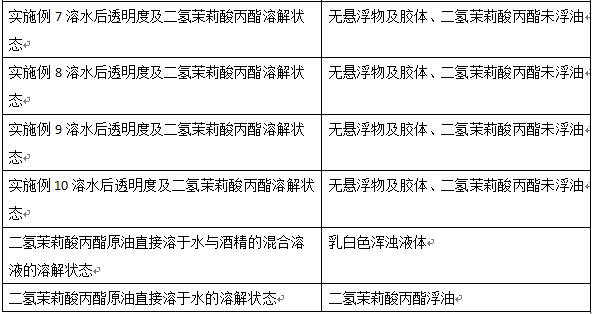

Propyl dihydrojasmonate soluble solution and preparation method thereof

PendingCN113973823AFacilitate the appearance of coloringEasy to synthesizeBiocidePlant growth regulatorsPhytotoxicityGrowth regulator

The embodiment of the invention relates to the technical field of plant growth regulators, in particular to a propyl dihydrojasmonate soluble solution which comprises the following components in percentage by weight: 1-40% of propyl dihydrojasmonate, 1-60% of an emulsifier and the balance of a solvent. The propyl dihydrojasmonate soluble solution has the beneficial effects that the solubility of the propyl dihydrojasmonate is improved, and the propyl dihydrojasmonate is easy to prepare; the compounding property of propyl dihydrojasmonate and the fertilizer can be improved, and the market demand is met; the spreadability and the absorption and utilization rate of propyl dihydrojasmonate in the use process can be increased, and the application effect of the product is improved; and the propyl dihydrojasmonate soluble solution has the advantages of low phytotoxicity, low toxicity and easiness in dilution, and is safe and convenient to use.

Owner:郑州尼采生物科技有限公司

A kind of preparation method of akd microemulsion

ActiveCN108385434BGood temperature toleranceStrong storage resistanceCoatings with pigmentsWater-repelling agents additionMicroemulsionChemistry

The invention discloses a preparation method of AKD microemulsion, comprising the following steps: mixing liquid AKD, an emulsifier and water at room temperature, heating and melting to obtain a mixture; stirring the mixture at a speed of 300-500r / min for 25 ‑30 minutes to form an emulsion; add co-emulsifier dropwise during stirring until the emulsion becomes clear and transparent, and AKD microemulsion is obtained after cooling down. The AKD microemulsion prepared by the preparation method of the invention has the advantages of good stability, storage resistance, small surface tension and the like.

Owner:山东晨鸣纸业集团股份有限公司

Carrot and egg noodles and processing and manufacture method thereof

The invention relates to carrot and egg noodles and processing and a manufacture method thereof, and belongs to the field of noodles processing. The carrot and egg noodles comprise the following ingredients in parts by weight: 8-12 parts of carrots, 8-12 parts of eggs, 70-90 parts of wheatmeal, 2-4 parts of table salt, 1-3 parts of guar gum and 20-35 parts of purified water. The manufacture methodcomprises the following steps of: smashing sliced and dried carrots in a pulverizer, screening by a sieve of 100 meshes to obtain carrot powders for standby; at a ratio, evenly mixing the eggs, the table salt, the guar gum and the water to obtain dough; at a ratio, adding the wheatmeal, the carrot powders and the dough in a flour machine to knead dough for 15-22 min to obtain a new dough; enabling the prepared dough to stand for fermentation; repeatedly rolling and extending the dough obtained after standing, cutting the dough into noodles, and drying the noodles until a water content is 8-10%; and finally, cutting off the dried noodles, weighting the noodles, and packaging the noodles. The carrot and egg noodles improve the color of the noodles to a maximum extent, show attractive faintred, have comprehensive and balanced nutrition through scientific compatibility, have a smooth taste, are high in gluten strength, have a special flavor, are high in storage resistance, are convenientin eating and have an extremely good selling prospect.

Owner:曾文标

Chopped peanut production process capable of controlling salmonella

The object of the present invention is to provide a chopped peanut production process capable of controlling salmonella. The production process includes the following steps: 1) removing impurities in raw materials; 2) sieving by a metal detector; 3) sterilizing by steam; 4) sterilizing by infrared rays; and 5) cutting into pieces and packing without oxygen. The beneficial effects of the present invention are that: through three automated continuous production processes of a high-temperature steam process, infrared sterilization (dry heat processing), and cutting into pieces and packing without oxygen, the production process can make the crashed peanut products have no salmonella residue, improve the safety of products, and enhance the market competitiveness of products. Besides, the crashed peanuts are easy to take, and high in storability, and are a nutritious food having market potential.

Owner:ZHONGDI FOODS

Processing and manufacturing method of alkaline water noodles

InactiveCN110810721AFull of nutritionNutritional balanceNatural extract food ingredientsFood ingredient functionsProcess engineeringGluten

The invention relates to alkaline water noodles and a processing and manufacturing method thereof, and belongs to the technical field of noodle processing. The noodles comprise the following components in parts by weight: 20-40 parts of oat bran, 60-100 parts of wheat flour, 2-4 parts of table salt, 1-3 parts of guar gum and 20-35 parts of purified water. The preparation method comprises the following steps: extracting plant alkaloid in the oat bran by utilizing an ultrasonic solvent; uniformly mixing the plant alkaloid, the table salt, the guar gum and the water in a proportion to obtain a dough kneading agent; proportionally putting the wheat flour and the dough kneading agent into a dough kneading machine, and kneading dough for 12-18 minutes to obtain a dough blank; standing the prepared dough blank for dough leavening, wherein the dough leavening time is 26-32 minutes; and repeatedly calendering the dough after standing, cutting the dough into strips, performing drying until the water content is 9-11%, finally cutting off the dried noodles, and performing weighing and packaging. The alkaline water noodles supplement alkaloid lacked in common noodles to the maximum extent, andare comprehensive and balanced in nutrition through scientific compatibility, smooth in taste, high in gluten strength, unique in flavor, high in storability, convenient to eat and extremely good in sales prospect.

Owner:曾文标

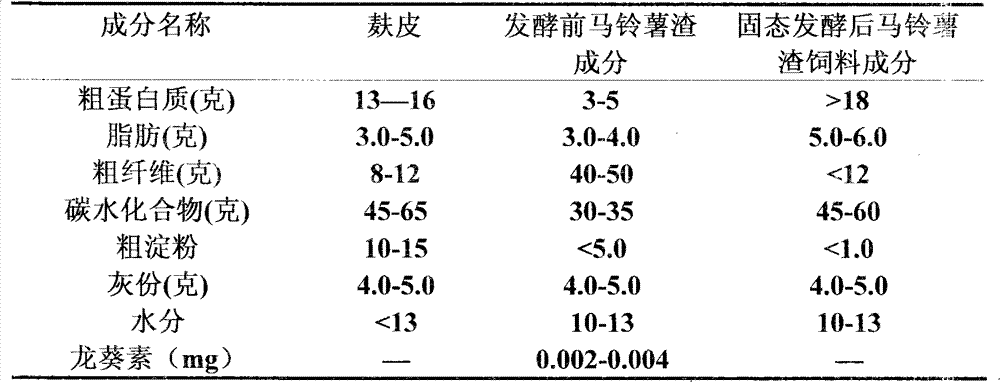

Potato pulp energy fermentation feed capable of replacing bran and preparation method thereof

The invention discloses a potato dregs fermentation energy fodder which can replace bran and a preparation method thereof. The principal raw material of the fodder is potato dregs which is prepared through zymohydrolysis and mixed culture solid-state fermentation by adding accessories of bran, urea, ammonium sulphate, monosodium orthophosphate and bitter salt; the preparation method comprises: preprocessing of material, zymohydrolysis of pectase and cellulase, expanding propagation of strains of production, preparation of liquid seed, mother culture and leaven, fermentation and parching; the invention has the advantages that: the potato dregs fodder prepared through fermentation by adopting the method has the content of crude protein of more than 18 percent, over sized fibres of less than10 percent and ash content of less than 5 percent, the potato dregs fodder can meet the standard of first level wheat bran according to <GB 10368-89 wheat bran for fodder>, has no solanine or other microelements with toxic effects, is rich in multiple Probiotic bacteria and has good flavor, and can be used as energy fodder for fowl and Livestock instead of bran.

Owner:QIQIHAR UNIVERSITY

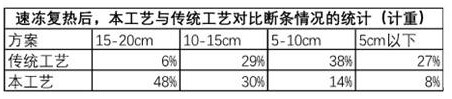

Making process of quick-frozen fried rice noodles and quick-frozen fried rice noodles

PendingCN113974059AStrong storage resistanceReduce consumptionFood freezingFood preservationSide dishProcess engineering

The invention discloses a making process of quick-frozen fried rice noodles and the quick-frozen fried rice noodles. The process comprises the following steps: S1, soaking dry rice noodles at normal temperature until the water content is not lower than 40%; s2, primarily curing and secondarily increasing the water content; s3, rolling and kneading for seasoning; S4, weighing and sub-packaging, adding the prepared side dishes into each sub-package, and preliminarily cooling to room temperature; and S5, quick-freezing. The gelatinization degree and the water content of the rice noodles are strictly controlled, aged water can still be absorbed by gelatinized structures during microwave heating, broken noodles are avoided, traditional stir-frying is replaced with rolling and kneading, large-scale production can be achieved, the whole process is free of the stir-frying procedure and only boiling is achieved, energy consumption is reduced, and mechanical operation is achieved. Labor loss is reduced, and assembly line work is easy to achieve. According to the method, operation is directly carried out on the dried rice noodles, the storage resistance of the dried rice noodles is superior to that of fresh rice noodles, and the problem that the fried rice noodles are easily made under the condition that no fresh rice noodle supply chain guarantee exists is solved.

Owner:董飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com