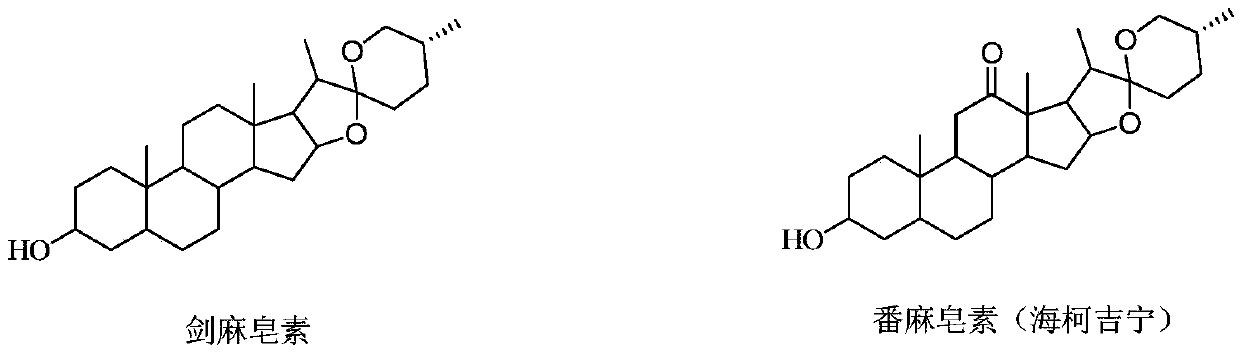

Method for extracting tigogenin and/or hecogenin with composite bacteria method

A technology of sisal saponin and compound bacteria, which is applied in the field of extracting sisal saponin and/or hecogenin, can solve the problems of low product yield and purity, environmental pollution toxicity, complicated process, etc., and achieves product yield and purity. The effect of improving, high economic efficiency and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

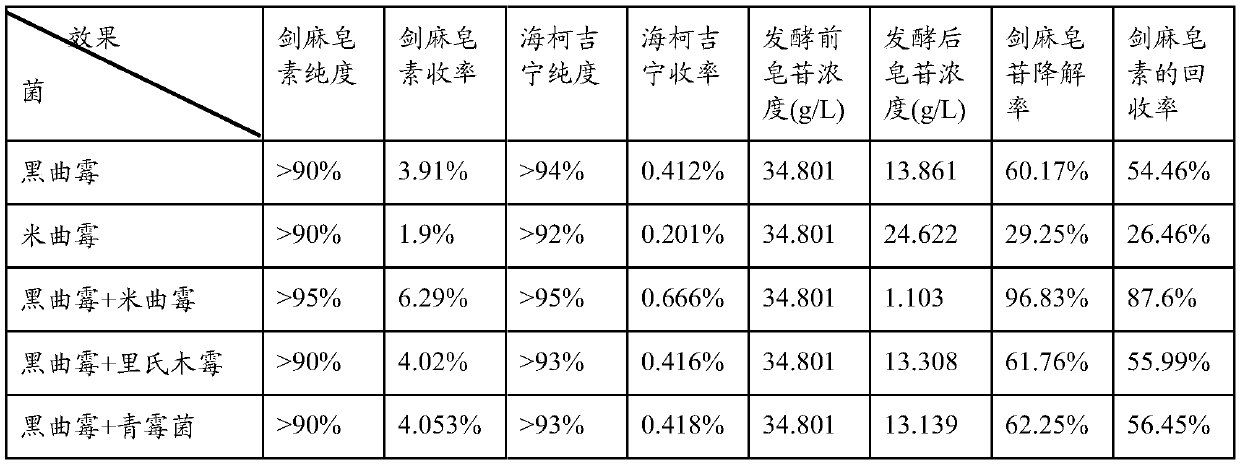

Embodiment 1

[0030] (1) Take 50Kg of sisal dry residue, add 100Kg of water, adjust the pH to 4.5 with citric acid-sodium hydroxide-hydrochloric acid buffer solution, add 500g of pectinase and 500g of cellulase, and stir for 4-5h to obtain a clear liquid 1.

[0031] (2) Appropriate amounts of Aspergillus niger and Aspergillus oryzae were inoculated into respective culture solutions (each 100 L) and fermented until the bacteria amount reached 15 mg / mL. The two fermentation broths were mixed with clear liquid 1, and stirred and reacted at a temperature of 37° C. for 2 days. Stand still for 48 hours, remove the supernatant, centrifuge the lower layer at 4000 rpm, remove the supernatant to obtain a total of 9.42Kg of precipitate 1, collect the supernatant and discard it after high-temperature sterilization.

[0032] (3) Mix the precipitate 1 with 1.884Kg quicklime, add 94.2Kg85% ethanol aqueous solution, heat and reflux at 79°C for 4h, add 1.413Kg gac, after reflux for 2h, centrifuge at 4500 r...

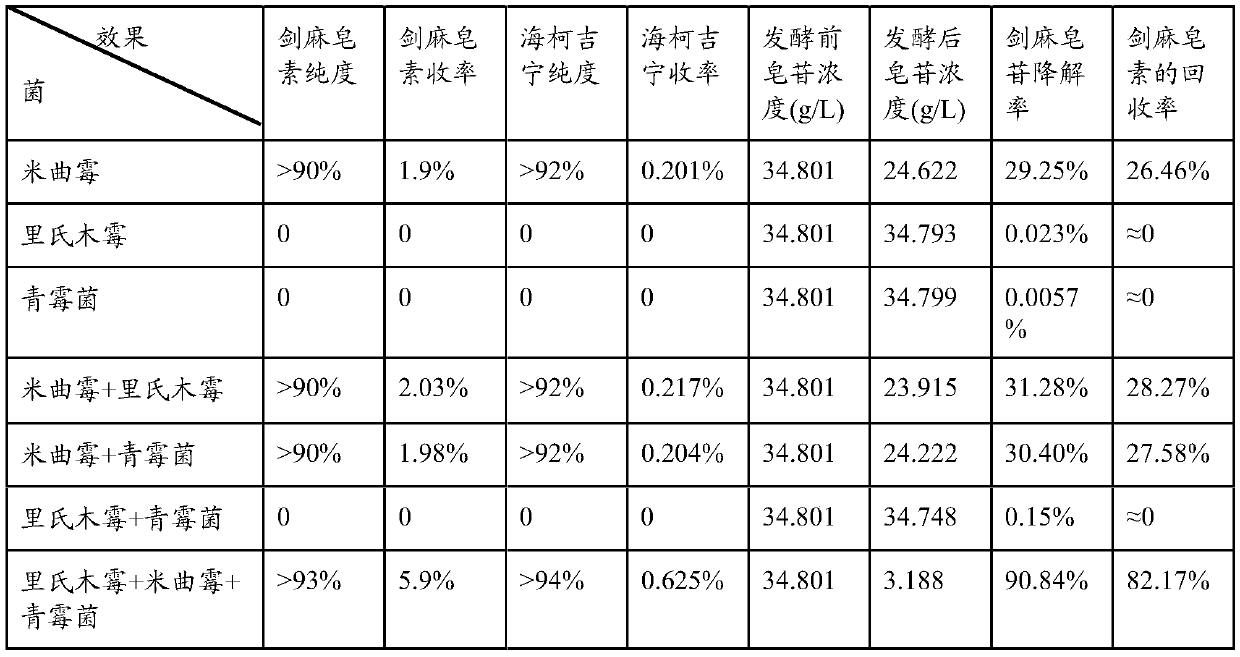

Embodiment 2

[0039] (1) Take 50Kg of sisal dry residue, add 100Kg of water, adjust the pH to 4.5 with citric acid-sodium hydroxide-hydrochloric acid buffer solution, add 500g of pectinase and 500g of cellulase, and stir for 4-5h to obtain a clear liquid 1.

[0040] (2) Inoculate an appropriate amount of Trichoderma reesei (Trichordermareesei), Aspergillus oryzae (Aspergillus oryzae) and Penicillium sp. into respective culture fluids respectively, wherein the culture fluid of Trichoderma reesei and Aspergillus oryzae is 100L, Penicillium sp. 50L of culture solution, fermented until the amount of bacteria is 15mg / mL. The three fermentation broths were evenly mixed with clear liquid 1, and stirred and reacted at a temperature of 37° C. for 2 days. Stand still for 48 hours, remove the supernatant, centrifuge the lower layer at 4000 rpm, remove the supernatant to obtain a total of 10.6Kg of precipitate 1, collect the supernatant and discard it after high-temperature sterilization.

[0041] (3...

Embodiment 3

[0047] 3.1 Replace Aspergillus niger+Aspergillus oryzae in embodiment 1 with Aspergillus niger

[0048] (1) Take 50Kg of sisal dry residue, add 100Kg of water, adjust the pH to 4.5 with citric acid-sodium hydroxide-hydrochloric acid buffer solution, add 500g of pectinase and 500g of cellulase, and stir for 4-5h to obtain a clear liquid 1.

[0049] (2) An appropriate amount of Aspergillus niger was inoculated into the culture medium (200 L) and fermented until the bacteria amount was 15 mg / mL. The supernatant liquid 1 was mixed with the fermentation broth, and stirred and reacted at a temperature of 37° C. for 2 days. Stand still for 48 hours, remove the supernatant, centrifuge the lower layer at 4000 rpm, remove the supernatant to obtain a total of 6.32Kg of precipitate 1, collect the supernatant and discard it after high-temperature sterilization.

[0050] (3) Mix the precipitate 1 with 1.264Kg quicklime, add 63.2Kg85% ethanol aqueous solution, heat and reflux at 79°C for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com