Biomass carbon base and copper and/or cuprous oxide hybrid material, and preparation method thereof

A cuprous oxide, hybrid material technology, applied in physical/chemical process catalysts, chemical instruments and methods, water pollutants, etc., can solve the problems of complex treatment process and high equipment requirements, and achieve high reaction efficiency and uniform particle size. The effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

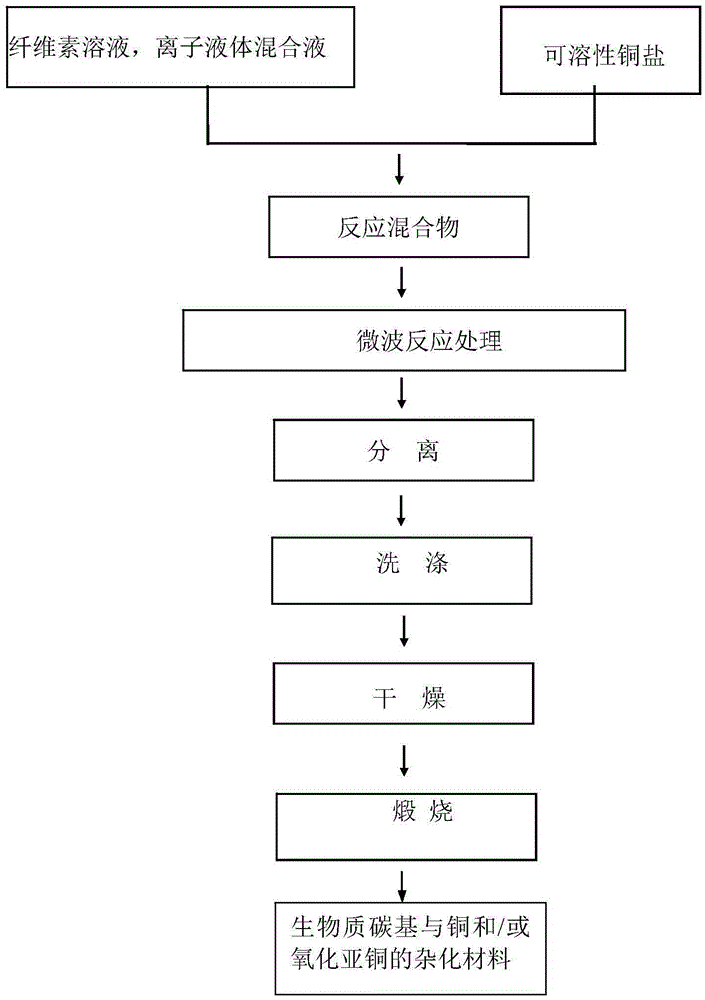

Method used

Image

Examples

Embodiment 1

[0038] 1) Dissolve 7.00g of sodium hydroxide and 12.00g of urea in 81ml of water and mix well to form a sodium hydroxide / urea solution; add 3.24g of microcrystalline cellulose to the obtained sodium hydroxide / urea mixture and mix well ; Then place the resulting mixture at -12°C for 12 hours to obtain a cellulose solution.

[0039] 2) At room temperature, mix 10 mL of the cellulose solution obtained in step 1) with 10 mL of 1-butyl-3-methylimidazolium tetrafluoroborate (ionic liquid, density about 1.22 g / ml), Wherein the mass ratio of cellulose to ionic liquid is about 1:37, then 0.33gCuCl 2 2H 2 O is added to the mixture and mixed evenly, where CuCl 2 2H 2 The mass ratio of O to the cellulose is about 1:0.95.

[0040] 3) Put the mixture obtained in step 2) into a microwave catalytic synthesizer (Xiangge Technology Co., Ltd., model XH-100A), turn on the power, and perform microwave treatment for 40 minutes at a temperature of 100±2°C. After the reaction was finished, the p...

Embodiment 2

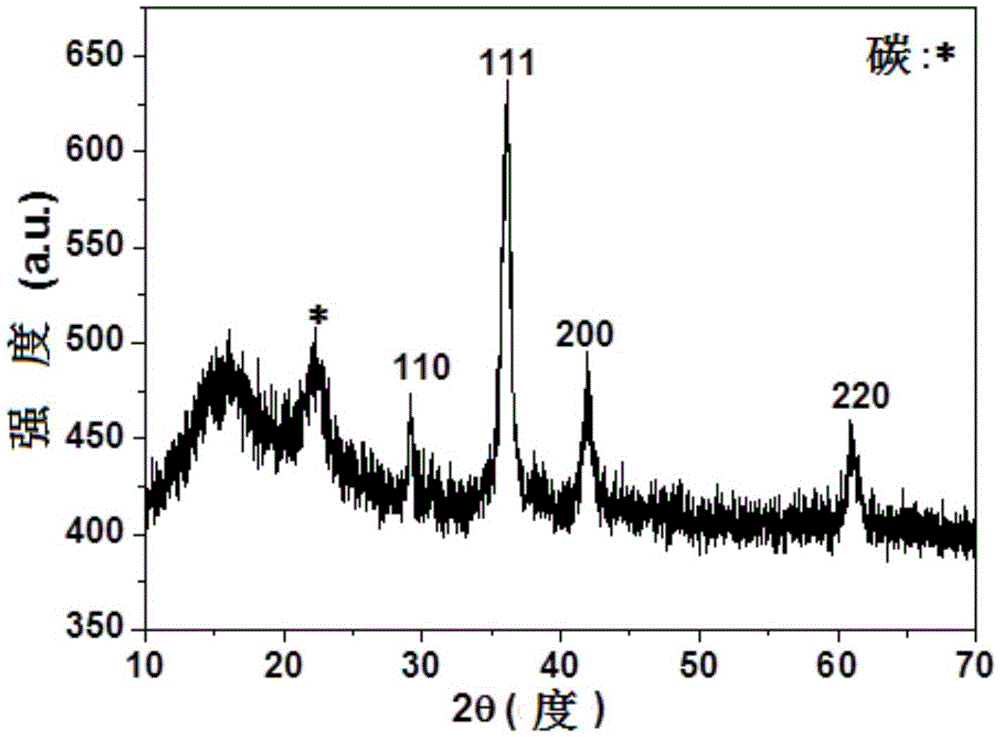

[0046] In addition to placing the precursor obtained after the microwave reaction in a vacuum / atmosphere tube furnace (Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., SK-G08123K), nitrogen gas was introduced, the air in the furnace was exhausted, and the temperature was raised to 5°C / min. 800°C, after calcination treatment at 800°C for 3h, cooled to room temperature, followed the same method as in Example 1 to prepare a hybrid material of biomass carbon base, copper and cuprous oxide.

[0047] The composition and purity of the prepared hybrid materials were analyzed by X-ray diffraction, such as image 3 shown. The diffraction peak at 2θ=36.7° in the X-ray diffraction spectrum corresponds to the (111) crystal plane of cuprous oxide, while the peaks at 2θ=43.5° and 50.6° correspond to the (111) and (200) crystal planes of copper, respectively . The X-ray diffraction spectrum of the product shows that the product contains both cuprous oxide and copper, indicating th...

Embodiment 3

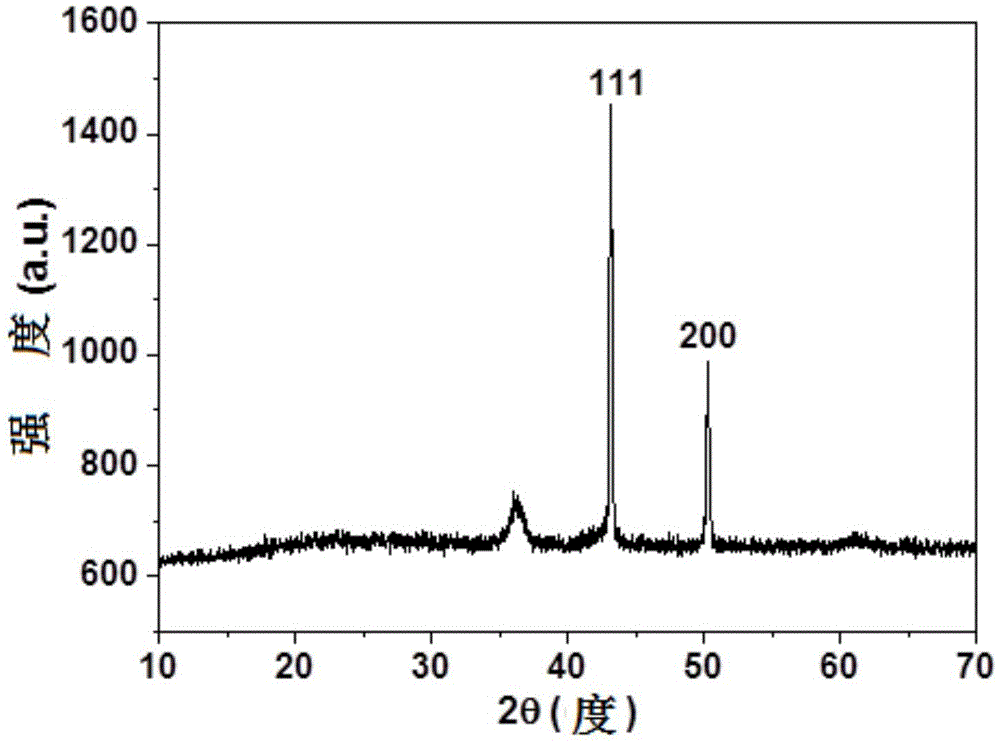

[0050] In addition to placing the precursor obtained after the microwave reaction in a vacuum / atmosphere tube furnace (Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., SK-G08123K), nitrogen gas was introduced, the air in the furnace was exhausted, and the temperature was raised to 5°C / min. 1000°C, after calcination treatment at 1000°C for 3h, cooled to room temperature, followed the same method as in Example 1 to prepare a hybrid material of biomass carbon-based and copper.

[0051] The composition and purity of the prepared hybrid materials were analyzed by X-ray diffraction, such as Figure 4 shown. The peaks at 2θ=43.5° and 50.6° in the X-ray diffraction spectrum correspond to the copper (111) and (200) crystal planes, respectively. The X-ray diffraction spectrum of the product shows that the product contains copper, indicating that the product is a hybrid material of biomass carbon-based and copper.

[0052] Figure 7 Scanning electron micrographs (SEM) of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com