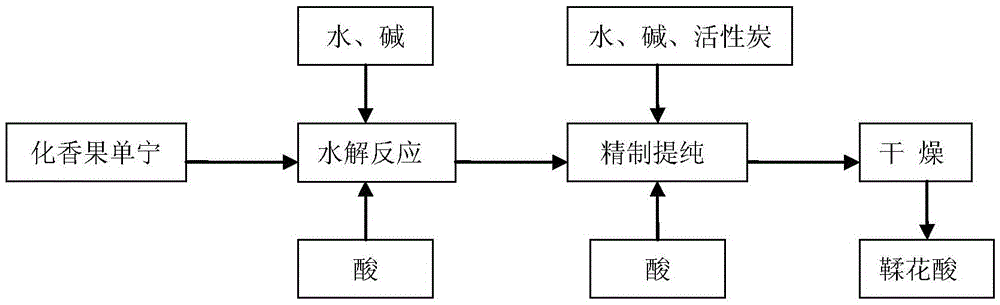

Method for preparing ellagic acid through basic hydrolysis of tannin in Platycarya strobilacea fruits

The technology of ellagic acid and tannin base is applied in the field of fine processing of plant tannin, which can solve the problems of complicated and complicated preparation process, expensive acid-resistant equipment, equipment corrosion, etc., and achieves a simple process, short reaction time and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 (extraction)

[0017] Crush the fragrant fruit and use water as the solvent to heat and extract. The extraction method can be conventional soaking, microwave-assisted extraction, ultrasonic-assisted extraction, the extraction temperature is 50-100°C, the number of extractions is 2-4 times, and the extraction time for each time After 1-3 hours, filter to remove the slag, heat and concentrate in a vacuum, and dry to obtain the fragrant fruit tannin. The details are as follows: 730g of the raw material of Huaxiang fruit sequence dried in the shade until the water content is 14.2wt%, remove the impurities, crush to 3-5mm, add 7300mL of pure aqueous solution at 70°C for 30min with ultrasonic assistance, filter the extract for solid-liquid separation, Repeat the extraction twice, discard the waste residue, and combine the extracts. The extract was cooled and allowed to settle overnight, and the precipitate was discarded. The supernatant was concentrated in vacuu...

Embodiment 2

[0019] Take 5g of citrus tannin, add 100mL of 0.75mol / L sodium hydroxide solution, and stir and hydrolyze for 60min at 100°C. Dilute hydrochloric acid was added to the reaction solution under stirring until the pH value of the reaction solution was 6, filtered, and the filter cake was washed with water to obtain a crude product of ellagic acid with a purity of 68.0% (HPLC method, the same below).

[0020] Add the crude product of ellagic acid into dilute sodium hydroxide solution, add activated carbon, react at 50°C for 1 hour, filter the reaction solution, wash the filter cake with water, combine the filtrate and washing solution; add dilute hydrochloric acid dropwise to adjust the pH of the solution When the pH value is 4, filter, and the filter cake is washed with water and dried to obtain 0.6 g of light yellow ellagic acid product with a content of 98.1%.

Embodiment 3

[0022] Take 10 g of citrus tannin, add 0.5 mol / L sodium hydroxide solution 300 mL, and stir and react at 90° C. for 60 min. Add dilute hydrochloric acid to the reaction solution while stirring until the pH value of the reaction solution is 5, filter, and wash the filter cake with water to obtain a crude product of ellagic acid with a purity of 65.6%. The crude product was refined and dried in the same manner as in Example 2 to obtain 1.2 g of a light yellow ellagic acid product with a content of 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com