Method for modifying perovskite solar cell light-absorbing layer

A solar cell and light-absorbing layer technology, applied in the field of solar cells, can solve the problems of uneven perovskite crystal size, affecting device performance repeatability, limiting battery performance, etc., and achieve low cost, performance improvement, and porosity reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

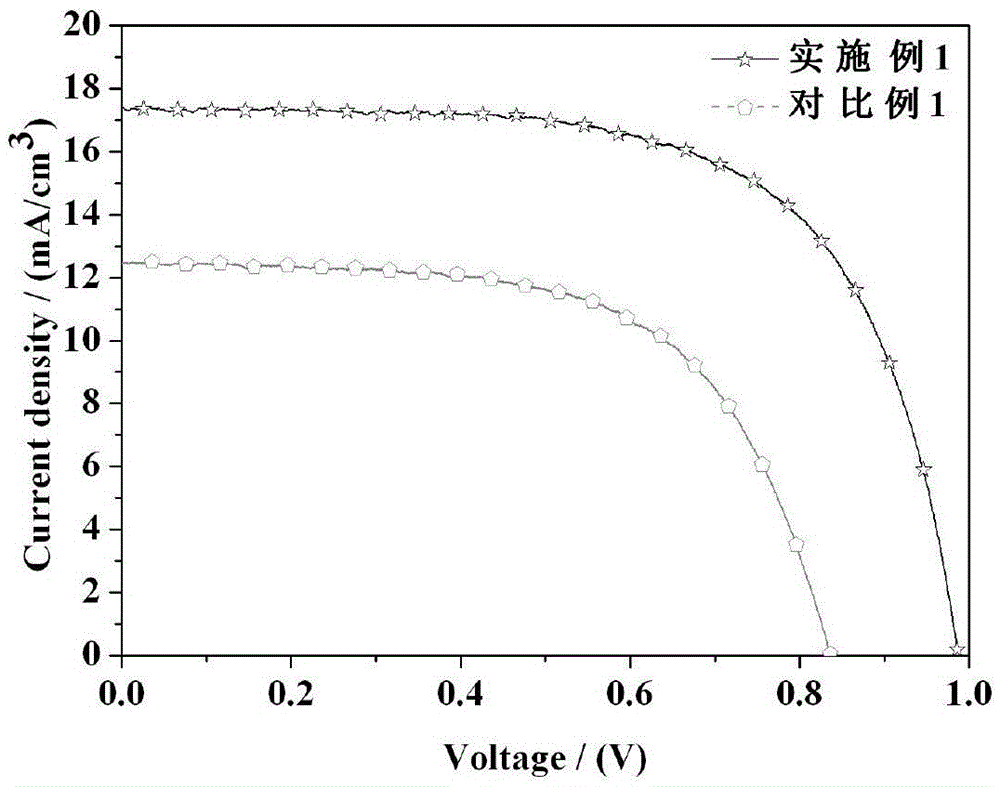

Examples

Embodiment 1

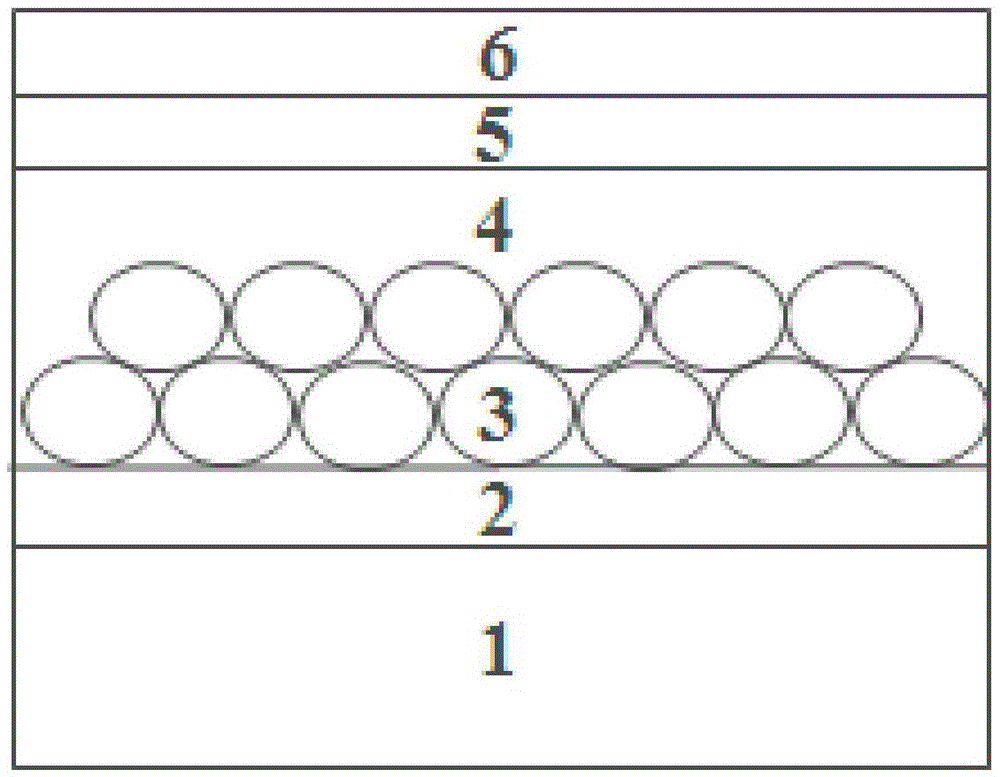

[0038] With FTO as the substrate, TiO2 as the hole blocking layer, TiO2 as the mesoporous layer, CH 3 NH 3 PB 3The preparation method of the perovskite solar cell as the light absorbing layer, Spiro-OMeTAD as the hole transport layer, and gold as the counter electrode:

[0039] Step 1: Cut the FTO glass into a size of 2cm×2cm, clean the surface with deionized water, acetone and absolute ethanol in sequence, and dry it with nitrogen gas for later use;

[0040] Step 2: Add 103 mg of diisopropyl bis(acetylacetonate) titanate to 1000 mg of 1-butanol, stir for 30 min, and mix well to obtain a mixed solution A;

[0041] Step 3: Spin-coat the mixed solution A on the surface of the FTO glass cleaned in step 1, bake at 125° C., and then anneal at 500° C. for 30 minutes to obtain a titanium dioxide hole blocking layer;

[0042] Step 4: Add 200 mg of titanium dioxide slurry into 700 mg of absolute ethanol, stir for 30 minutes, and mix it evenly to obtain a mixed solution B;

[0043] ...

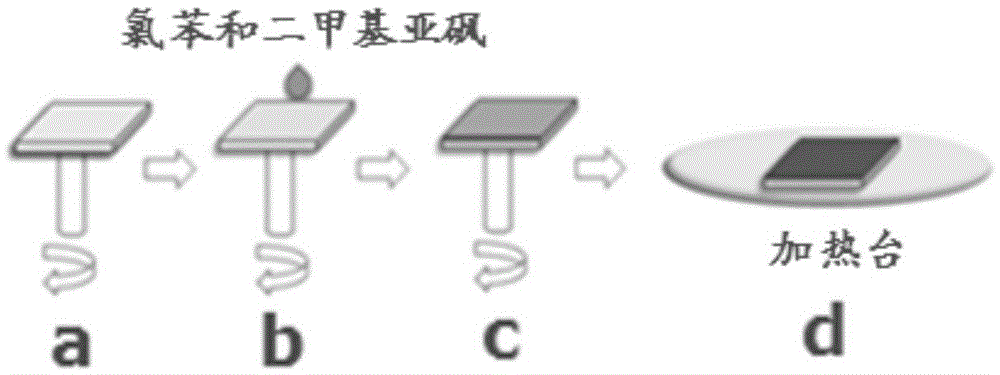

Embodiment 2

[0061] The difference between this example and Example 1 is that the modification solution in step 7 is a mixture of chlorobenzene and N,N-dimethylformamide, and the volume of the chlorobenzene and N,N-dimethylformamide The ratio is 19:1. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com