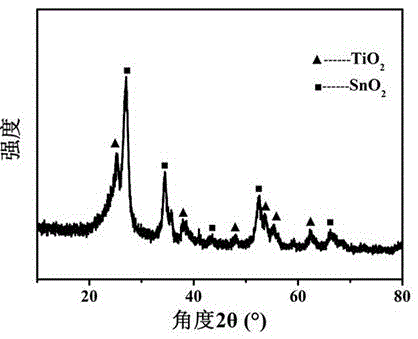

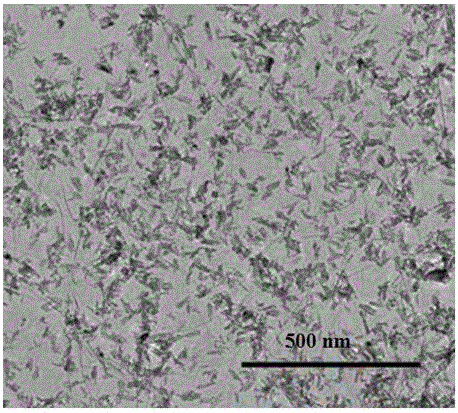

SnO<2>-TiO<2>@ graphene ternary composite nanomaterial and preparation method thereof

A ternary composite, nanomaterial technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limited application, and achieve good dispersion, mild conditions, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Use a measuring cylinder to measure 40ml deionized water and 20ml ethanol respectively, put them into a beaker and mix them evenly;

[0020] b. Weigh 50 mg of pyrolysis-reduced graphene oxide with an electronic balance and add it to the above solution for 2 h to make it evenly mixed;

[0021] c. Add 550mg CTAB to the above mixed solution, stir evenly, add 2ml concentrated hydrochloric acid, and continue stirring for 40min;

[0022] d. Weigh 50mg SnCl with an electronic balance 2 2H 2 O was added to the above solution, continued to stir for 1h, and then added 50mg TiOSO 4 In the above solution, continue stirring for 1 h;

[0023] e. Pour the above mixed solution into a high-pressure reactor with a polytetrafluoroethylene liner, and react at 180°C for 24 hours;

[0024] f. After the reaction is completed, take the product out of the reactor, wash and centrifuge it repeatedly with deionized water and ethanol, and dry the product at 60°C to obtain the uniform SnO pre...

Embodiment 2

[0027] The preparation process and steps of this embodiment are basically the same as in Example 1, except that the d step:

[0028] Weigh 50mgSnCl with an electronic balance 2 2H 2 O was added to the above solution, continued to stir for 1h, and then added 100mg TiOSO 4 In the above solution, continue to stir for 1h.

[0029] The obtained results are basically similar to those of Example 1, except that in the obtained nanomaterials, more oxide particles are aggregated and cannot be completely loaded on the graphene.

PUM

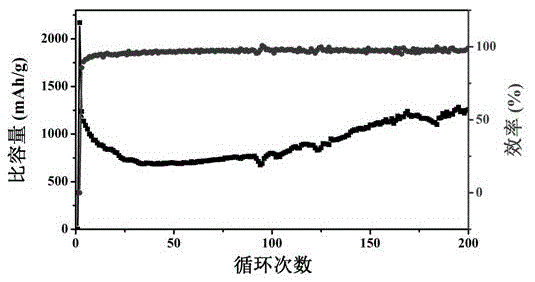

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com