Nitrogen-doped carbon-coated titanium niobate composite electrode material and preparation method thereof

A nitrogen-doped carbon and composite electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low conductivity and poor rate performance, achieve low production costs, enhance conductivity, and facilitate large-scale industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Weigh anatase titanium dioxide and niobium pentoxide according to the atomic ratio Ti:Nb=1:6.2, and then weigh a certain amount of cyanamide, wherein the mass of cyanamide is the total mass of titanium oxide and niobium oxide 10%, these three kinds of materials are joined in the ball mill tank, with absolute ethanol as the medium, ball milled for 24 hours at a speed of 300 rev / min on the ball mill;

[0032] b. drying the slurry obtained in step a at 60° C. to obtain a powder mixture;

[0033] c. Calcining the powder mixture obtained in the above step b at 1350° C. for 42 hours under nitrogen protection, and cooling to obtain a nitrogen-doped carbon-coated titanium niobate composite electrode material.

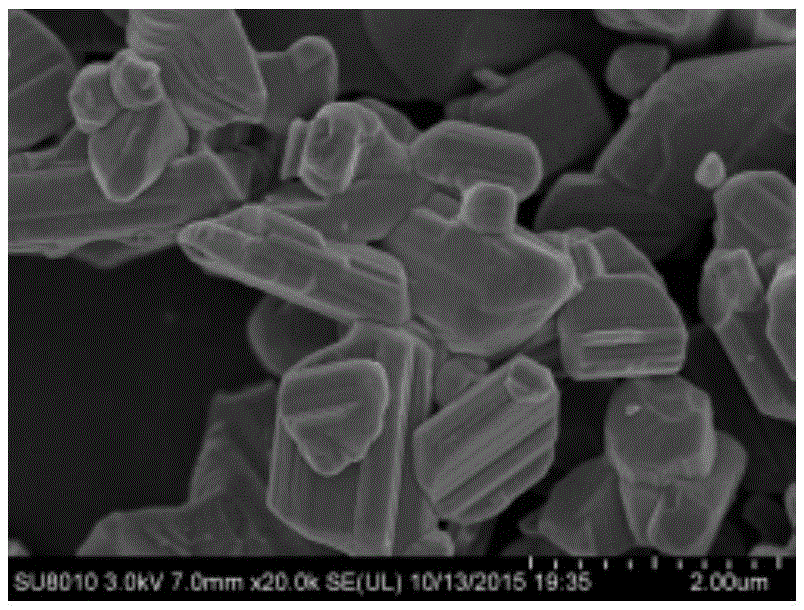

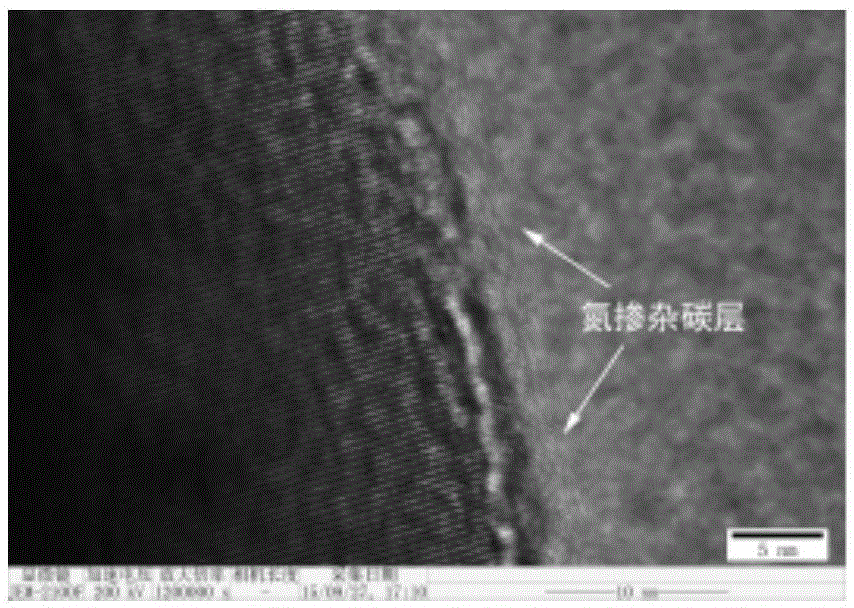

[0034] The experimental results of the nitrogen-doped carbon-coated titanium niobate composite electrode material prepared in Example 1 are as follows Figure 1-Figure 4 shown.

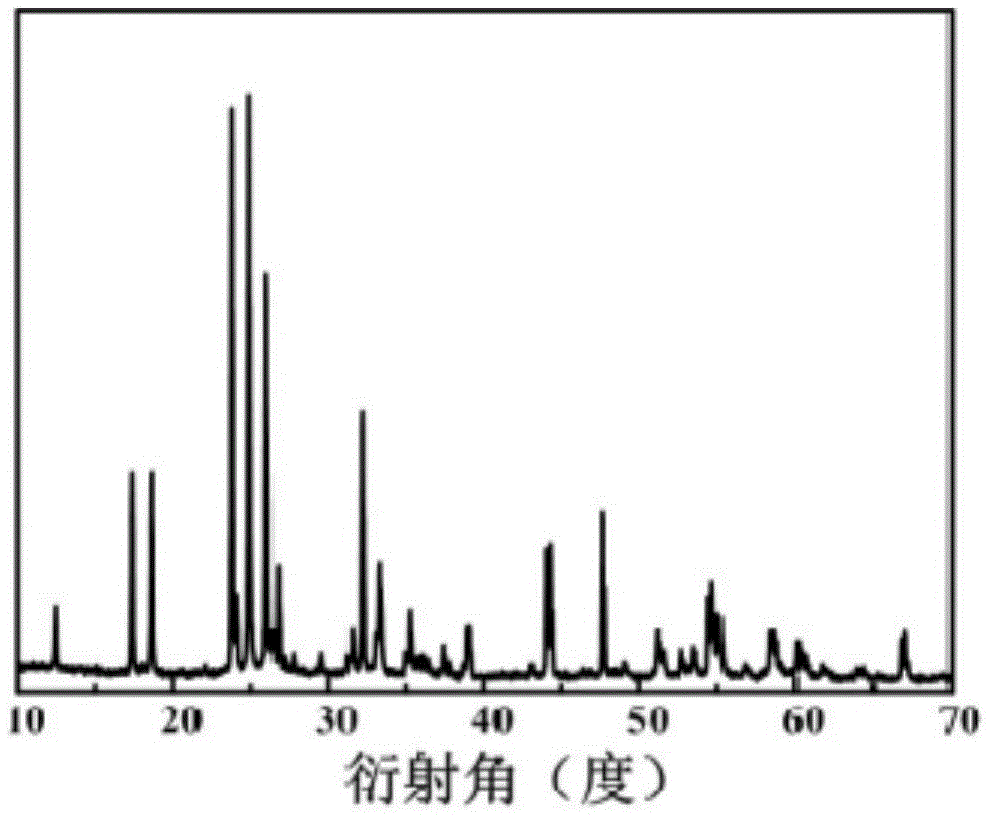

[0035] figure 1 For the XRD figure of the titanium niobate composite electrode materia...

Embodiment 2

[0040] a. Take by weighing P25 and niobium dioxide by atomic ratio Ti:Nb=1:5.8, and then weigh a certain amount of cyanamide, wherein the quality of cyanamide is 15% of the total mass of titanium oxide and niobium oxide. Three kinds of materials are added in the ball mill tank, with acetone as the medium, ball milling with a speed of 610 rpm on the ball mill for 31 hours;

[0041] b. Dry the slurry obtained in step a at 112°C to obtain a powder mixture;

[0042] c. Calcining the powder mixture obtained in the above step b under the protection of helium at 1000° C. for 41 hours, and cooling to obtain a nitrogen-doped carbon-coated titanium niobate composite electrode material.

Embodiment 3

[0044] a. Weigh titanium monoxide and niobium trioxide according to the atomic ratio Ti:Nb=1:5.7, and then weigh a certain amount of melamine, wherein the quality of melamine is 20% of the total mass of titanium oxide and niobium oxide. These three kinds of materials are added in the ball mill jar, with absolute ethanol as the medium, on the ball mill with 230 rev / min speed ball mill for 12 hours;

[0045] b. drying the slurry obtained in step a at 74°C to obtain a powder mixture;

[0046]c. Calcining the powder mixture obtained in the above step b at 960° C. for 58 hours under the protection of helium, and cooling to obtain a nitrogen-doped carbon-coated titanium niobate composite electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com