Carbon nitride/tungsten trioxide nano composite material and preparation method and application thereof

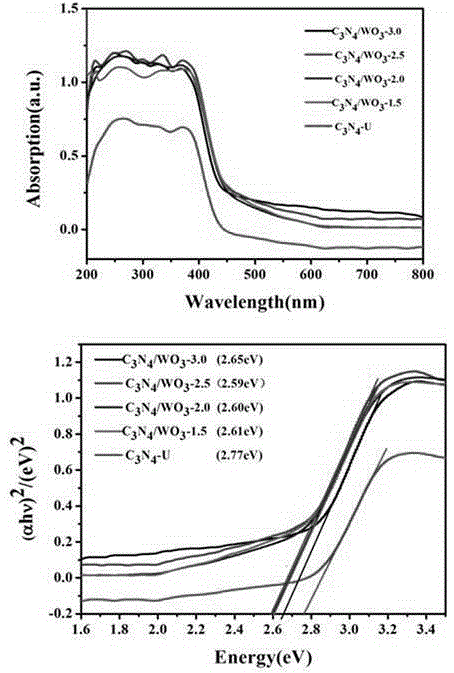

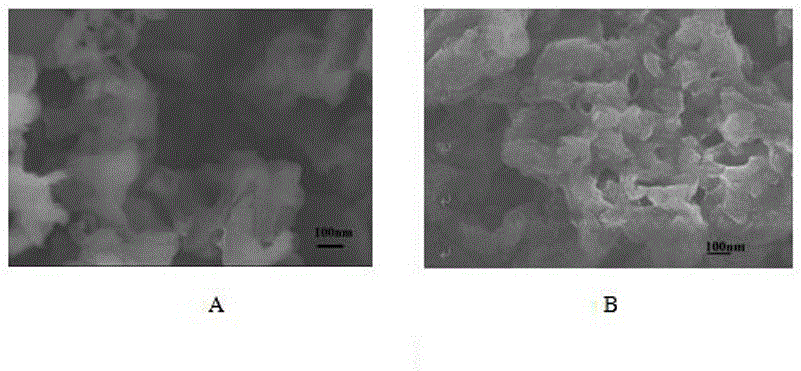

A nano-composite material, tungsten trioxide technology, applied in the field of nano-materials, can solve the problems of high carrier recombination rate, easy to be corroded by light, hindering application, etc. The method is simple and easy to control, simple and fast, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

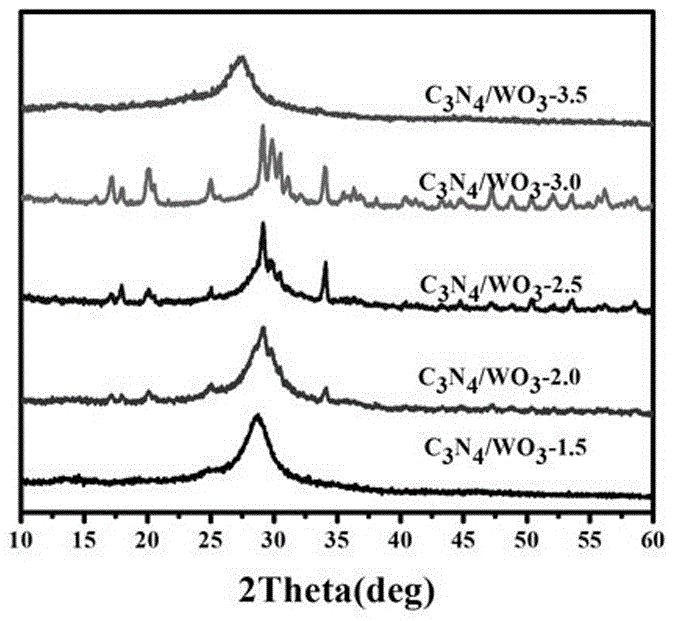

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of carbon nitride / tungsten trioxide nanocomposite material of the present invention is:

[0054] (1) Dissolve 0.1g sodium tungstate, 3.5g urea and 1.5g dicyandiamide in a mixed solution of 10ml deionized water and 30ml absolute ethanol, stir at 100°C to precipitate crystals, and dry the obtained crystals at 75°C , grind to obtain white powder;

[0055] (2) Put the white powder into a covered crucible and bake it in a muffle furnace at 400°C for 2 hours to polymerize at a heating rate of 3.1°C / min to obtain a yellow solid, which is ground and collected;

[0056] (3) Stir the yellow powder obtained in step (2) with 50ml of 1M HCl for 24h to make it completely protonated. Rinse with a large amount of distilled water, then filter with suction, dry at 75°C, and grind to obtain a yellow powder;

[0057] (4) Put the yellow powder into a covered crucible and bake it in a muffle furnace at 550°C for 2 hours to polymerize at a heating rate of 4.4°C / min to...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is: sodium tungstate is 0.1 g, urea is 3.0 g and dicyandiamide is 2.0 g, and the rest are the same as embodiment 1.

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is that: sodium tungstate is 0.1 g, urea is 2.5 g and dicyandiamide is 2.5 g, and the rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com