Method for treating caprolactam production wastewater

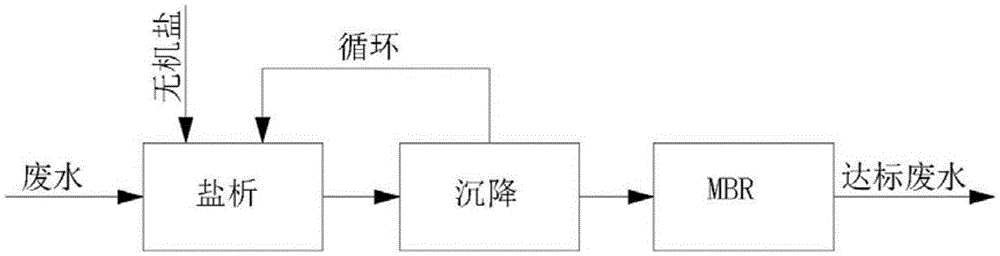

A technology of caprolactam and wastewater production, which is applied in the direction of special treatment targets, natural water treatment, chemical instruments and methods, etc., can solve the problems of shortened effective service life of MBR devices, high content of viscous impurities, increased operating costs, etc., to reduce chemical cleaning The number of times, reduce energy consumption, and improve the effect of equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the caprolactam production wastewater of a domestic chemical company, the COD of the rearrangement sub-plant wastewater is 11400mg / L, and the total nitrogen (TN) content is 275mg / L.

[0039] Caprolactam waste water enters reactor, adds ammonium sulfate to make its concentration maintain 15wt%, control reactor temperature 50 ℃, pressure-0.08Mpa, stirring rate 800r / min, pure water content keeps on 63wt%, enter sedimentation system after staying 15min, to In the overflow tank, 10g / t of waste water is added to the flocculant for sedimentation and stratification, and the supernatant liquid is returned to the reactor, and the return flow is repeated until the indicators in the system are stable. At this time, the wastewater in the reactor is continuously introduced, the water is continuously evaporated, and the flocs are continuously precipitated. The wastewater containing flocs is continuously introduced into the overflow tank and the sedimentation process continues, and t...

Embodiment 2

[0041] The caprolactam production wastewater of a chemical company in China has a COD of 12100mg / L and a total nitrogen (TN) content of 284mg / L.

[0042] Caprolactam waste water enters reactor, adds ammonium sulfate to make its concentration maintain 21wt%, control reactor temperature 40 ℃, pressure-0.08Mpa, stirring speed 800r / min, pure water content keeps on 75wt%, after staying 15min, enter sedimentation system, to In the overflow tank, 8g / t of waste water is added to the flocculant for sedimentation and stratification, and the supernatant liquid is refluxed to the reactor, and the reflux is repeated until the various indicators in the system are stabilized. At this time, the wastewater in the reactor is continuously introduced, the water is continuously evaporated, and the flocs are continuously precipitated. The wastewater containing flocs is continuously introduced into the overflow tank and the sedimentation process continues, and the supernatant is continuously returned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com