A kind of polymetallic silicide powder and preparation method thereof

A technology of metal silicide and silicide, which is applied in the direction of metal silicide, can solve the problems of long nitriding heat treatment time, etc., and achieve the effect of adjustable hardness and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

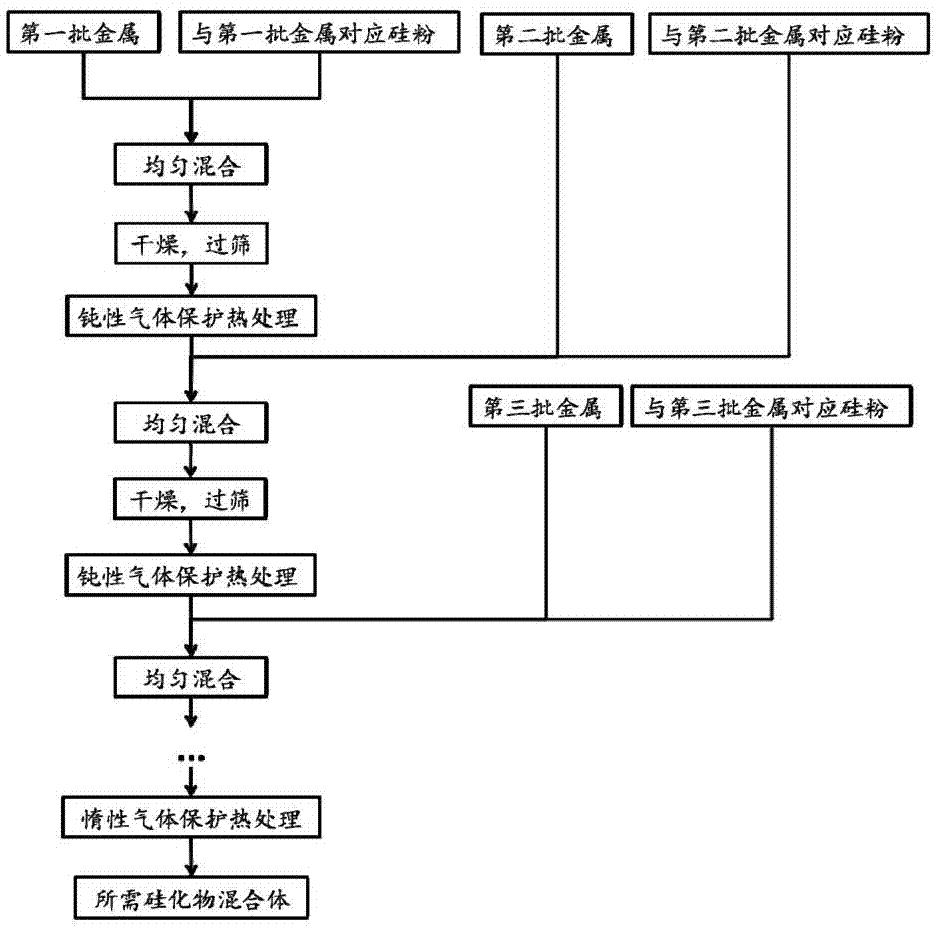

Method used

Image

Examples

Embodiment 1

[0041] Example 1:

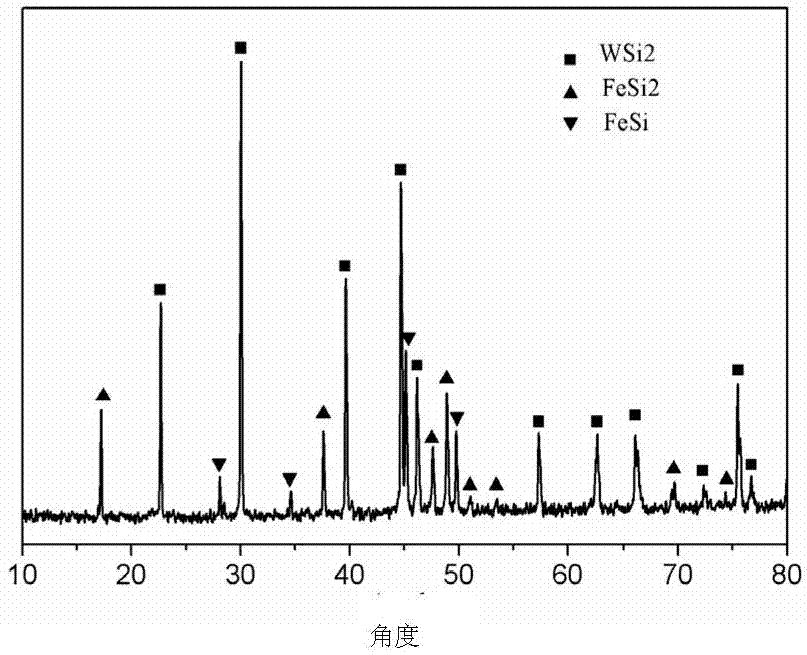

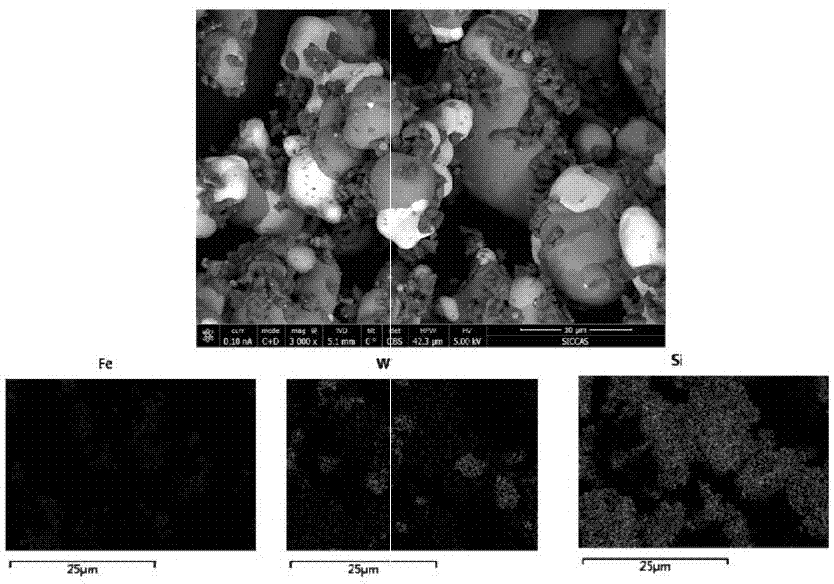

[0042] Synthesized m by two heat treatments WSi2 :m FeSi2 = 1:1 WSi 2 / FeSi 2 Adjacent or wrapped structure powder

[0043] 1) Mixing for the first time: Mix 100g of tungsten powder and silicon powder according to the atomic ratio of 1:2, add silicon nitride balls or alumina balls, add 45g of absolute ethanol and mix, and ball mill for 1.5h;

[0044] 2) Drying and sieving: blow dry at 40°C for 3 hours, and pass through a 60-mesh sieve;

[0045] 3) The first heat treatment: heat treatment at 1450°C for 3 hours in an argon protective atmosphere;

[0046] 4) The second mixing: add 100g of iron powder and silicon powder with an atomic ratio of 1:2 to the powder obtained by heat treatment, 100g of silicon nitride balls or alumina balls, and 120g of absolute ethanol, mix and ball mill for 2 hours;

[0047] 5) Drying and sieving: air-dry at 40°C for 5 hours, and pass through a 60-mesh sieve;

[0048] 6) The second heat treatment: heat treatment at 1250°C fo...

Embodiment 2

[0051] Synthesized m by two heat treatments MoSi2 :m FeSi2 = 1:2 MoSi 2 / FeSi 2 Adjacent or wrapped structure powder

[0052] 1) Mixing for the first time: Mix 60g of molybdenum powder and silicon powder according to the atomic ratio of 1:2, add silicon nitride balls or alumina balls, add 45g of absolute ethanol and mix, and ball mill for 1.5h;

[0053] 2) Drying and sieving: blow dry at 40°C for 3 hours, and pass through a 60-mesh sieve;

[0054] 3) The first heat treatment: heat treatment at 1300°C for 5 hours in an argon protective atmosphere;

[0055] 4) The second mixing: add 120g of iron powder and silicon powder with an atomic ratio of 1:2 to the heat-treated powder, mix with 100g of silicon nitride balls or alumina balls, and 120g of absolute ethanol, and ball mill for 2 hours;

[0056] 5) Drying and sieving: air-dry at 40°C for 5 hours, and pass through a 60-mesh sieve;

[0057] 6) The second heat treatment: heat treatment at 1200° C. for 5 hours in an argon pro...

Embodiment 3

[0059] Synthesized m by two heat treatments Mo5Si3 :m Cr3Si = Mo of 3:1 5 Si 3 / Cr 3 Si adjacent or wrapped structure powder

[0060] 1) Mixing for the first time: mix 150g of molybdenum powder and silicon powder according to the atomic ratio of 5:3, add 60g of absolute ethanol to 80g of silicon nitride balls or alumina balls, mix, and ball mill for 1.5h;

[0061] 2) Drying and sieving: blow dry at 40°C for 3 hours, and pass through a 60-mesh sieve;

[0062] 3) The first heat treatment: heat treatment at 1800°C for 0.5h in an argon protective atmosphere;

[0063] 4) Second mixing: Add 50g of chromium powder and silicon powder with an atomic ratio of 3:1, 100g of silicon nitride balls or alumina balls, and 120g of absolute ethanol to the powder obtained by heat treatment, and ball mill for 2 hours;

[0064] 5) Drying and sieving: air-dry at 40°C for 5 hours, and pass through a 60-mesh sieve;

[0065] 6) The second heat treatment: heat treatment at 1400° C. for 0.5 h in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com