Method for separating and purifying salt in 2,4,5-triamino-6-hydroxy pyrimidine sulfate production process

A technology for the production process of hydroxypyrimidine, which is applied in the field of synthesis of pharmaceutical intermediates, can solve the problems of high hazardous waste treatment and disposal costs, high operating costs, and expensive one-time investment, and achieve the elimination of hazardous waste generation, reduction of wastewater discharge, Favorable effect of biological treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

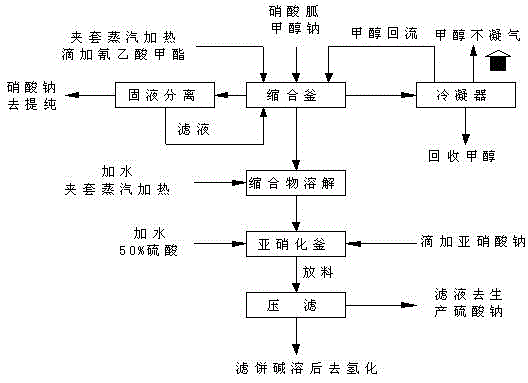

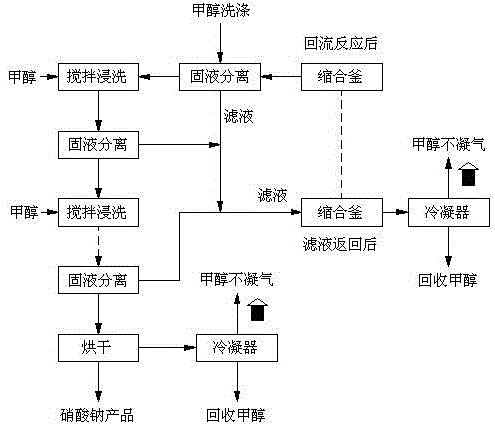

[0023] Put 330kg of guanidine nitrate into the dry 1000L jacketed condensation kettle, and then add 480kg of 30% sodium methoxide. When the jacket steam is heated to 45℃, 265kg of methyl cyanoacetate is added dropwise. When it reaches 1 / 3, watch the reflux, continue dripping without flushing, the dripping time is about half an hour, after dripping, the materials in the reactor will undergo condensation reaction at 67-70℃ to form the condensate 2.4-diamino -6-Hydroxypyrimidine. After refluxing for four hours, put the material into a closed centrifuge for solid-liquid separation. After the separation is completed, 150L methanol is used for centrifugal washing. The filtrate and washing liquid are pumped into the condensation kettle; the sodium nitrate filter cake washed with methanol is stirred and immersed with 300L methanol After centrifugal separation, the methanol solution is collected into the condensation kettle. Distill and condense the methanol in the recondensing kettle ...

Embodiment 2

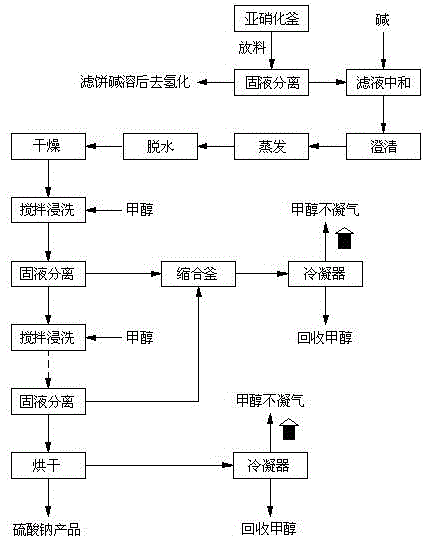

[0025] In the 5000L nitrosation kettle with condensate, add 1100L of water and 300L of 50% sulfuric acid. When the temperature does not exceed 30℃, add 606L of dissolved 30% sodium nitrite to the nitrosation kettle for 0.5-1 hour. After the dripping is completed, after the end point is detected with a test paper, the temperature is kept for 1 hour, and the material is discharged and filtered to obtain the nitroso compound 2.4-diamino-5-nitroso-6-hydroxypyrimidine and the press filtrate. The filtrate was neutralized to neutrality with 30% sodium hydroxide 56L, clarified to remove solid impurities, evaporated, dried and dehydrated to obtain crude sodium sulfate; 200L methanol was used to stir and soak the crude sodium sulfate, and then centrifuged, methanol solution Collect the condensation kettle and the filtrate of Example 1 together with distillation and condensation to recover methanol and distillation residues; dry the centrifuged sodium sulfate, heat it to 65°C or more, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com