Conductive polyaniline nanocomposite microwave absorbing material production method

A technology of microwave absorbing material and conductive polyaniline, applied in the field of functional materials, can solve the problems of weak absorption strength, narrow frequency band, high density, etc., and achieve the effects of simple operation, wide frequency band and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

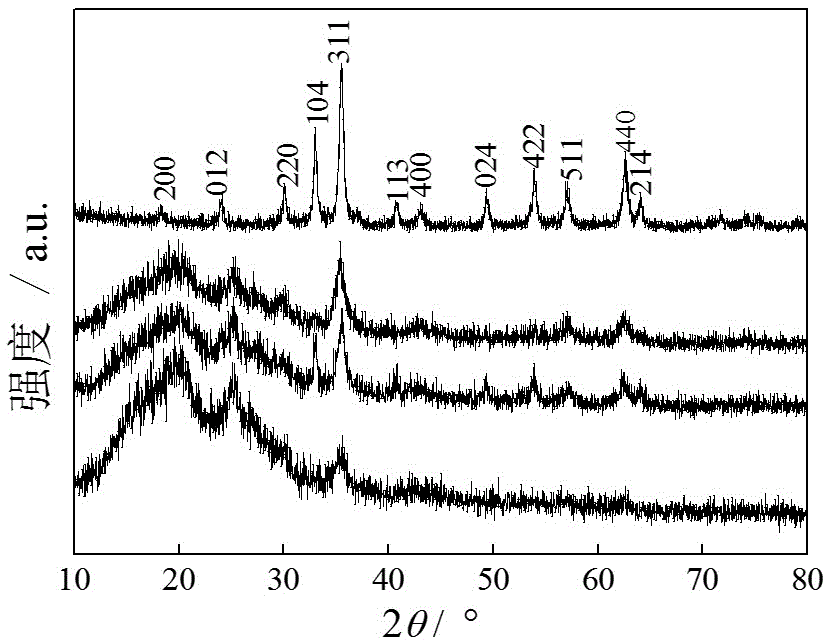

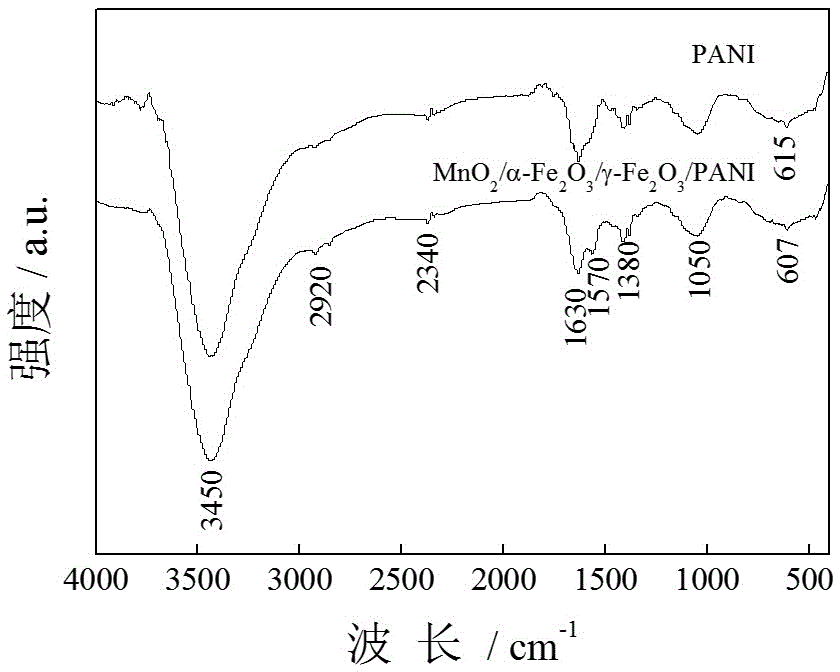

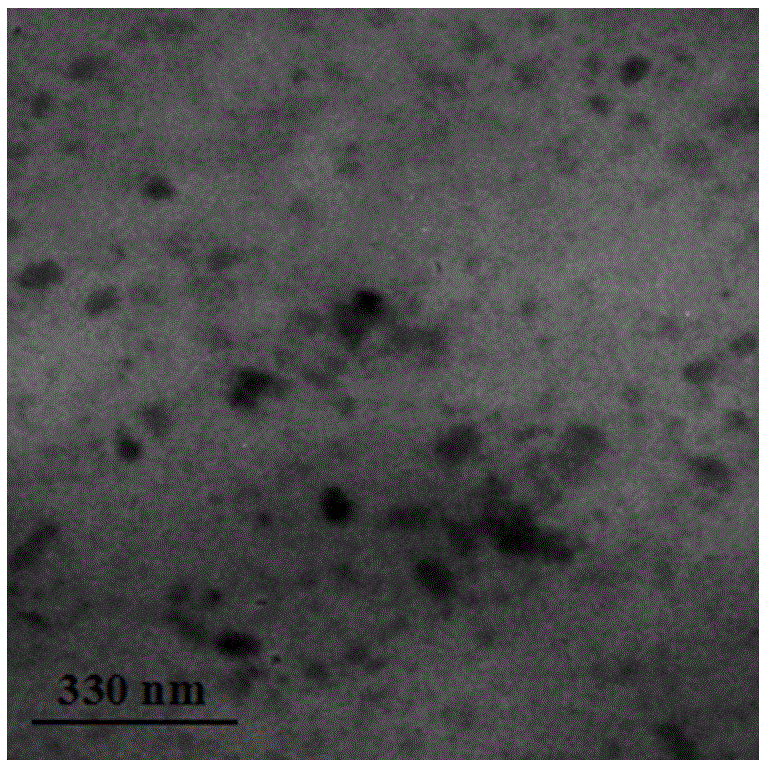

Image

Examples

Embodiment 1

[0035] The specific operation steps for preparing conductive polyaniline nanocomposite microwave absorbing material are as follows:

[0036] (1) Preparation of manganese dioxide and ferric oxide composite materials

[0037]Disperse 0.05406g of manganese dioxide into 70mL of the mixed solution and ultrasonicate for 30min; then add 0.5406g of ferric chloride hexahydrate to dissolve evenly; add 0.24g of sodium hydroxide and stir evenly, transfer the above mixed solution into a hydrothermal kettle, Reaction at 180°C for 12 hours; vacuum drying at 60°C for 12 hours to obtain a composite material of manganese dioxide and ferric oxide;

[0038] The 70mL mixed solution is made by mixing 20mL ethylene glycol and 50mL deionized water;

[0039] (2) Preparation of conductive polyaniline nanocomposite microwave absorbing materials

[0040] Add 0.0255g of the composite material into 70mL of deionized water, ultrasonically disperse for 30min, add 1.9233g of dodecylbenzenesulfonic acid, sti...

Embodiment 2

[0045] The specific operation steps for preparing conductive polyaniline nanocomposite microwave absorbing material are as follows:

[0046] (1) Preparation of manganese dioxide and ferric oxide composite materials

[0047] Disperse 0.05406g of manganese dioxide into 70mL of the mixed solution and ultrasonicate for 30min; then add 0.5406g of ferric chloride hexahydrate to dissolve evenly; add 0.24g of sodium hydroxide and stir evenly, transfer the above mixed solution into a hydrothermal kettle, Reaction at 180°C for 12 hours; vacuum drying at 60°C for 12 hours to obtain a composite material of manganese dioxide and ferric oxide;

[0048] The 70mL mixed solution is made by mixing 20mL ethylene glycol and 50mL deionized water;

[0049] (2) Preparation of conductive polyaniline nanocomposite microwave absorbing materials

[0050] Add 0.0511g of the composite material into 70mL of deionized water, ultrasonically disperse for 30min, add 1.9233g of dodecylbenzenesulfonic acid, st...

Embodiment 3

[0055] The specific operation steps for preparing conductive polyaniline nanocomposite microwave absorbing material are as follows:

[0056] (1) Preparation of manganese dioxide and ferric oxide composite materials

[0057] Disperse 0.05406g of manganese dioxide into 70mL of the mixed solution and ultrasonicate for 30min. Then add 0.5406g of ferric chloride hexahydrate, dissolve evenly; add 0.24g of sodium hydroxide, stir evenly, transfer the above mixed solution into a hydrothermal kettle, and react for 20h at 160°C; Dry for 12 hours to obtain a composite material of manganese dioxide and ferric oxide;

[0058] The 70mL mixed solution is made by mixing 30mL ethylene glycol and 40mL deionized water;

[0059] (2) Preparation of conductive polyaniline nanocomposite microwave absorbing materials

[0060] Add 0.0766g of the composite material into 70mL of deionized water, ultrasonically disperse for 30min, add 1.4532g of dodecylbenzenesulfonic acid, stir mechanically for 10min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com