ABS noctilucent masterbatches and preparation method thereof

A technology of ABS resin and masterbatch, applied in the field of ABS luminous masterbatch and its preparation, can solve the problems of low luminous efficiency, screw wear, low luminous content concentration, etc., to avoid metal pollution, reduce extrusion rate, ABS molecular weight big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

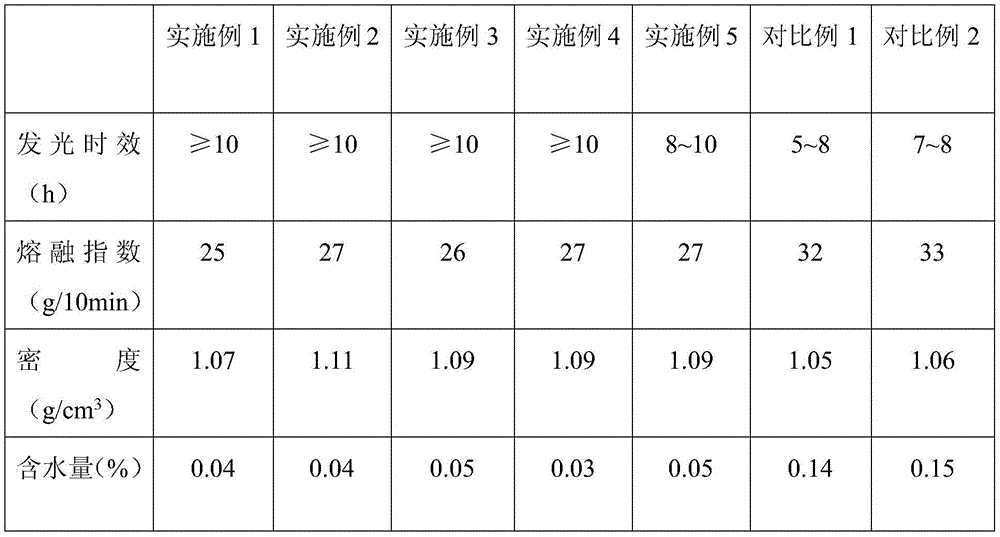

Examples

Embodiment 1

[0022] An ABS luminous masterbatch, its components are proportioned by mass percentage as follows:

[0023] Granular ABS resin 52.5%, powdered ABS resin 20%, polyethylene wax 6%, simethicone 1.5%, luminous powder 20%.

[0024] Preparation method: Weigh each component according to the weight ratio, add it into a plastic barrel, mix it in a mixer with a speed of 60r / min for 3 minutes, and after mixing evenly, add it into a single-screw extruder with a speed of 100r / min In 180°C-200°C, melt and knead at a temperature of 180°C to 200°C, then extrude and granulate, then dry and package to obtain ABS luminous masterbatch.

Embodiment 2

[0026] An ABS luminous masterbatch, its components are proportioned by mass percentage as follows:

[0027] Granular ABS resin 40%, powdered ABS resin 20%, polyethylene wax 8%, simethicone 2%, luminous powder 30%.

[0028] Preparation method: Weigh each component according to the weight ratio, add it into a plastic barrel, mix it in a mixer with a speed of 60r / min for 3 minutes, and after mixing evenly, add it into a single-screw extruder with a speed of 100r / min In 200°C, melt and knead at a temperature of 200°C, extrude and granulate, then dry and package to obtain ABS luminous masterbatch.

Embodiment 3

[0030] An ABS luminous masterbatch, its components are proportioned by mass percentage as follows:

[0031] Granular ABS resin 47.5%, powdered ABS resin 20%, polyethylene wax 6%, simethicone 1.5%, luminous powder 25%.

[0032] Preparation method: Weigh each component according to the weight ratio, add it into a plastic barrel, mix it in a mixer with a speed of 60r / min for 3 minutes, and after mixing evenly, add it into a single-screw extruder with a speed of 120r / min In 180°C-200°C, melt and knead at a temperature of 180°C to 200°C, then extrude and granulate, then dry and package to obtain ABS luminous masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com