Antibacterial type nanofiber composite material and preparation method thereof

A nanofiber and composite material technology, applied in the field of antibacterial nanofiber composite material and its preparation, can solve the problems of low filtration efficiency, particle filtration and antibacterial can not be taken into account at the same time, large filtration resistance, etc., to achieve simple preparation method and low cost , the effect of low filter resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

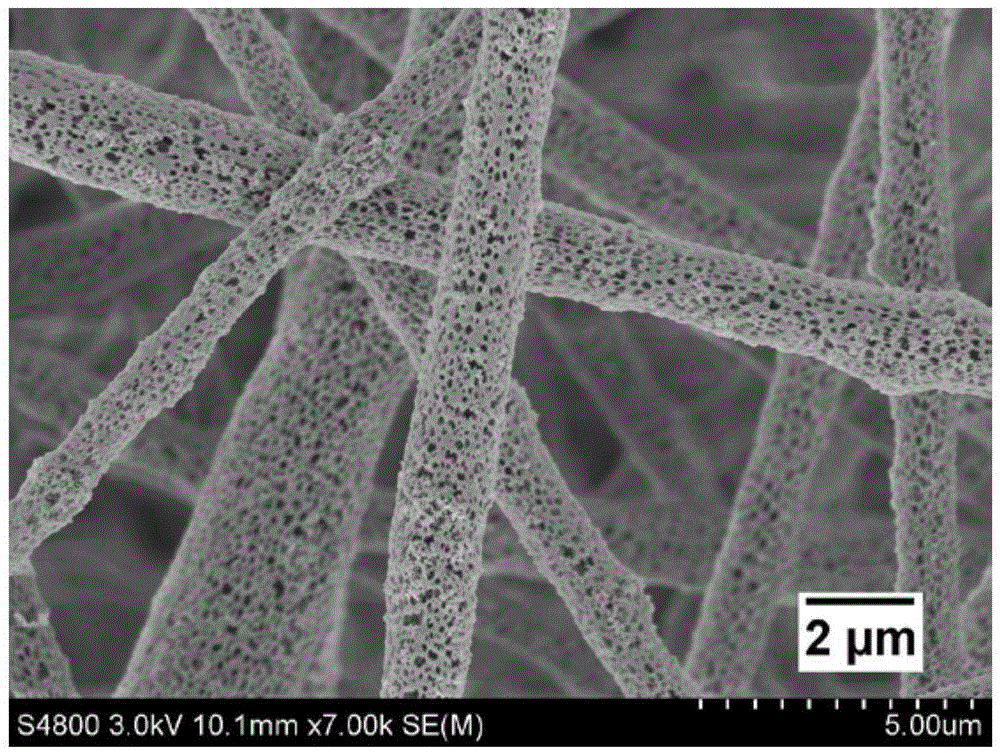

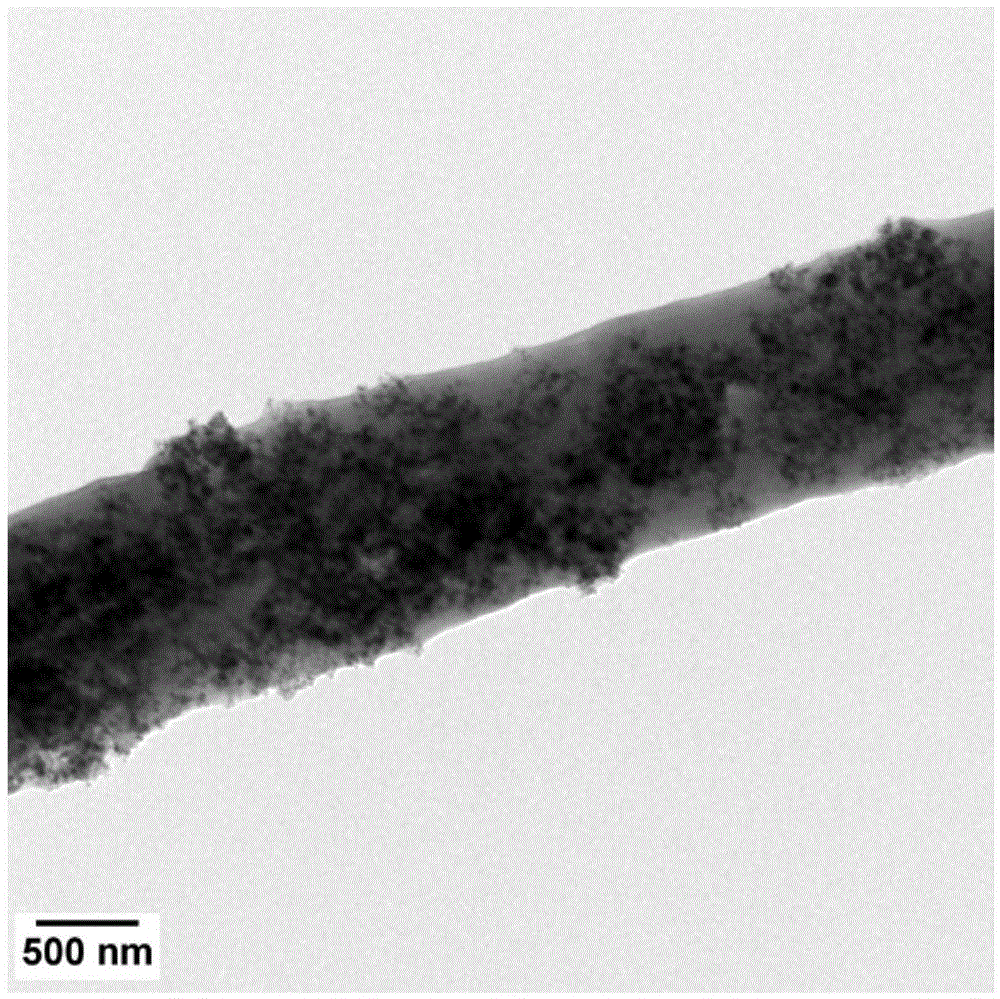

[0026] A certain mass of TiO 2 The nanoparticles were added to a mixed solvent of dichloromethane (DCM) and N,N-dimethylacetamide (DMAC) with a mass ratio of 10:1, ultrasonically oscillated for 90 minutes, and then a certain mass of PLA polymer was added. , at room temperature after magnetic stirring for 24h, and finally ultrasonic vibration treatment for 60 minutes. The mass fraction of PLA is 7%, TiO 2 A homogeneous solution with a mass fraction of nanoparticles of 1.75%.

[0027] will contain TiO 2 The homogeneous solution of nanoparticles was injected into 5 needle cylinders placed on one side of the receiving drum, the spinning voltage was 23kV, the spinning solution flow rate was 1ml / h, the spinning distance was 12cm, and the ambient relative humidity (RH) was 45% Electrospinning was carried out under the conditions.

[0028] Electrospinning was performed for 1 h under the above process conditions, and the TiO in the porous hybrid fiber membrane was measured. 2 The ...

Embodiment 2

[0030] A certain mass of TiO 2 The nanoparticles were added to a mixed solvent of dichloromethane (DCM) and N,N-dimethylacetamide (DMAC) with a mass ratio of 10:1, ultrasonically oscillated for 90 minutes, and then a certain mass of PLA polymer was added. , at room temperature through magnetic stirring for 24h, and finally ultrasonic vibration treatment for 60 minutes. The mass fraction of PLA is 7%, TiO 2 A homogeneous solution with a mass fraction of nanoparticles of 1.75%.

[0031] will contain TiO 2 The homogeneous solution of nanoparticles was injected into 5 needle cylinders placed on one side of the receiving drum, and the spinning voltage was 23kV, the flow rate of the spinning solution was 1ml / h, the spinning distance was 12cm, and the ambient relative humidity (RH) was 60. % conditions for electrospinning.

[0032] Electrospinning was performed for 1 h under the above process conditions, and the TiO in the porous hybrid fiber membrane was measured. 2The mass per...

Embodiment 3

[0034] A certain mass of TiO 2 The nanoparticles were added to a mixed solvent of dichloromethane (DCM) and N,N-dimethylacetamide (DMAC) with a mass ratio of 10:1, ultrasonically oscillated for 90 minutes, and then a certain mass of PLA polymer was added. , stirred by a magnetic stirrer for 24h at room temperature, and finally treated with ultrasonic vibration for 60 minutes. The mass fraction of PLA is 7%, TiO 2 A homogeneous solution with a mass fraction of nanoparticles of 1.75%.

[0035] will contain TiO 2 The homogeneous solution of nanoparticles was injected into 5 needle cylinders placed on one side of the receiving drum, and the spinning voltage was 23kV, the spinning solution flow rate was 1ml / h, the spinning distance was 12cm, and the ambient relative humidity (RH) was 15. % conditions for electrospinning.

[0036] Electrospinning was performed for 1 h under the above process conditions, and the TiO in the porous hybrid fiber membrane was measured. 2 The mass pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com