Chlorinating and shrink-proofing mercerization method for wool tops

A wool top and mercerizing treatment technology, applied in the field of fabrics, can solve the problems of wool fiber surface damage, wool fiber strength damage, etc., and achieve the effect of small loss of wool strength, small yellowing of wool, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

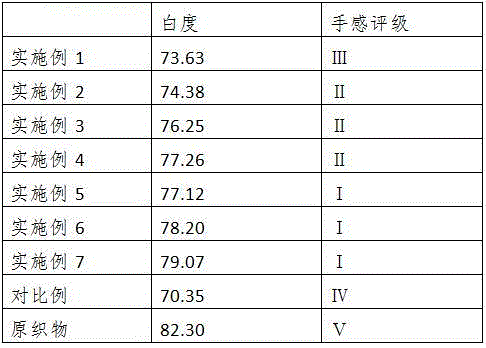

Examples

Embodiment 1

[0027] The chlorinated anti-shrinkage mercerizing treatment method of the wool top of embodiment 1 comprises the steps:

[0028] S1: Put the wool top after the needle opening treatment in the penetrating agent aqueous solution with a pH value of 3.5, add a chlorine-containing descaling agent to the aqueous solution, react at room temperature for 20 minutes, and then export the wool top;

[0029] S2: import the wool top obtained in S1 into the reduction treatment solution, raise the temperature to 33°C, keep the temperature for 1.5h, and then raise the temperature to 80°C for 20min;

[0030] S3: Place the wool tops obtained in S2 in a hydrolysis solution containing protease and peptidase, soak at 42°C for 30 minutes, wash and dehydrate with washing solution, and repeat the washing and dehydration operation twice;

[0031] S4: placing the wool obtained in S3 in an aqueous solution containing an anti-shrinkage agent and a softener, washing, drying, and needle carding again to obt...

Embodiment 2

[0035] The difference between Example 2 and Example 1 lies not only in the formula of the treatment solution, but also in the process parameters of dechlorination, reduction, hydrolysis and softening and anti-shrinkage treatment, specifically: the chlorination and anti-shrinkage mercerizing treatment of wool tops in Example 2 The method includes the following steps:

[0036] S1: Put the wool top after the needle opening treatment in the penetrating agent aqueous solution with a pH value of 4.5, add a chlorine-containing descaling agent to the aqueous solution, react at room temperature for 10 minutes, and then export the wool top;

[0037] S2: import the wool top obtained in S1 into the reduction treatment solution, raise the temperature to 38°C, keep the temperature for 1 hour, and then raise the temperature to 90°C and keep it for 10 minutes;

[0038] S3: Place the wool tops obtained in S2 in a hydrolysis solution containing protease and peptidase, soak at 50°C for 20 minutes,...

Embodiment 3

[0043] The chlorinated anti-shrinkage mercerizing treatment method of the wool top of embodiment 3 comprises the steps:

[0044] S1: Put the wool top after the needle card opening treatment in an aqueous penetrant solution with a pH value of 4, add a chlorine-containing descaling agent to the aqueous solution, react at room temperature for 15 minutes, and then export the wool top;

[0045] S2: import the wool top obtained in S1 into the reduction treatment solution, raise the temperature to 35°C, keep the temperature for 1.2h, and then raise the temperature to 85°C for 15min;

[0046] S3: Place the wool top obtained in S2 in a hydrolysis solution containing protease and peptidase, soak at 46°C for 25 minutes, wash and dehydrate with washing solution, and repeat the washing and dehydration operation 3 times;

[0047] S4: soft, the wool obtained in S3 is placed in an aqueous solution containing an anti-shrinkage agent and a softener, washed, dried, and needled again to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com