Preparation method of high-reliability bipolar plate for bipolar lead storage battery

A lead-acid battery and reliability technology, applied in the field of bipolar plate preparation, can solve the problem of weak bonding between the substrate and the active material, and achieve the effects of high reliability and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: a kind of preparation method of the high-reliability bipolar plate that is used for bipolar lead-acid storage battery described in this embodiment is specifically carried out according to the following steps:

[0024] 1. Pretreatment:

[0025] The titanium plate is degreased and pickled sequentially to obtain the pretreated titanium plate;

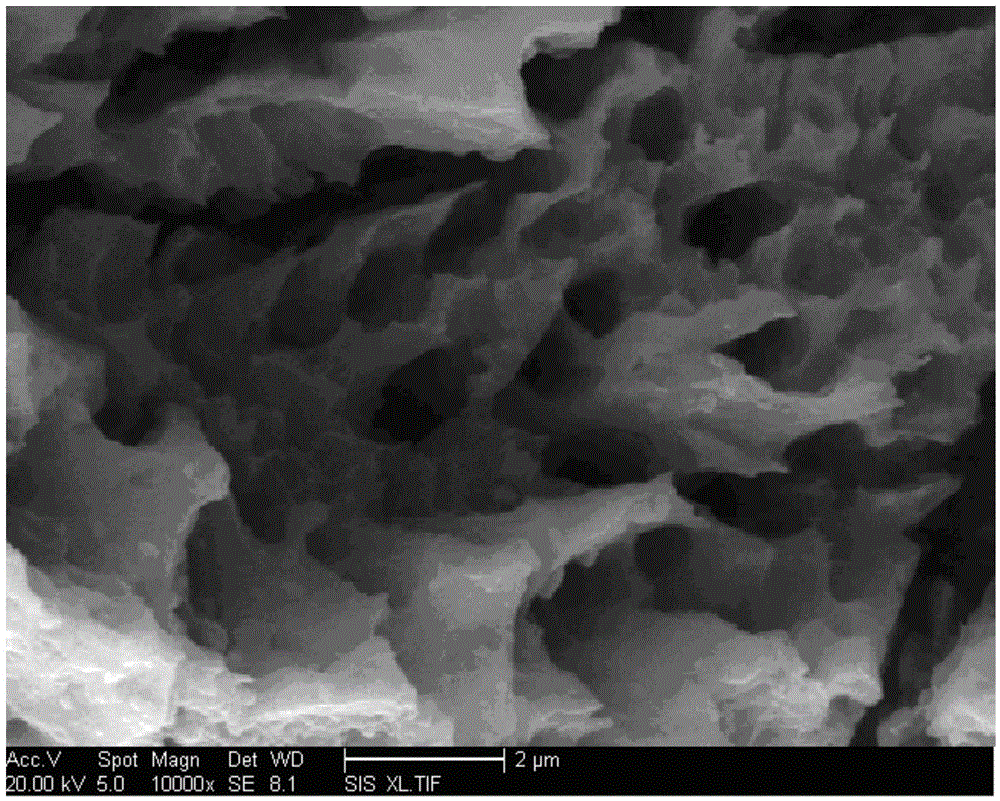

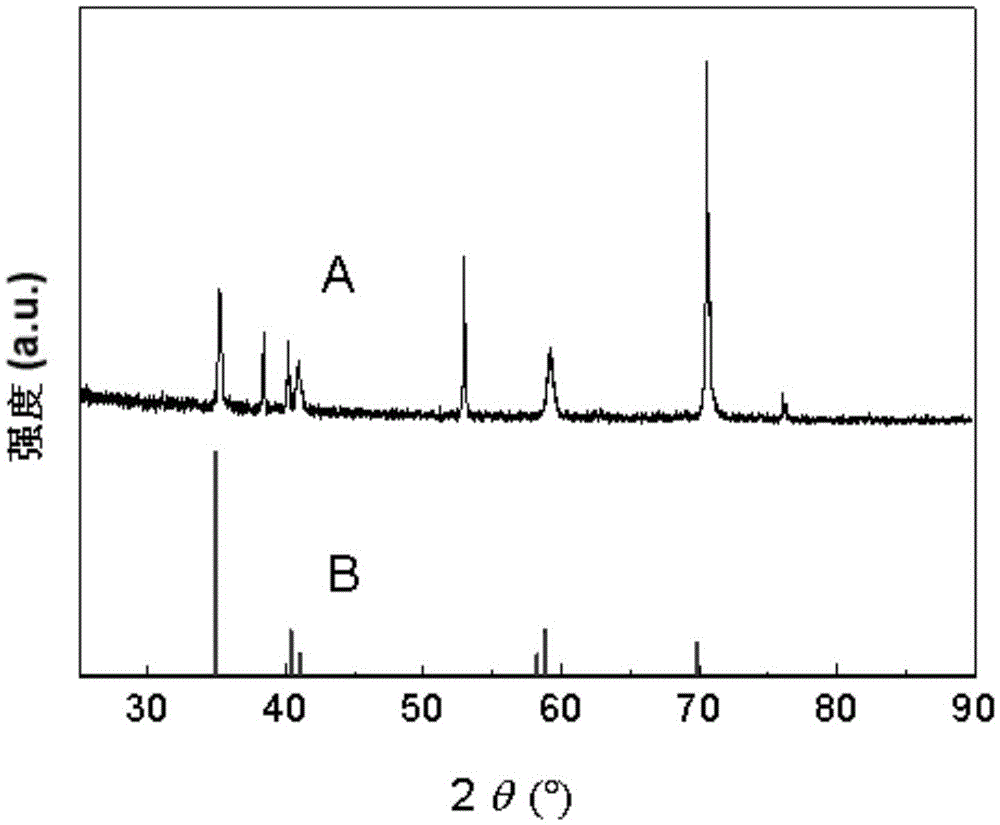

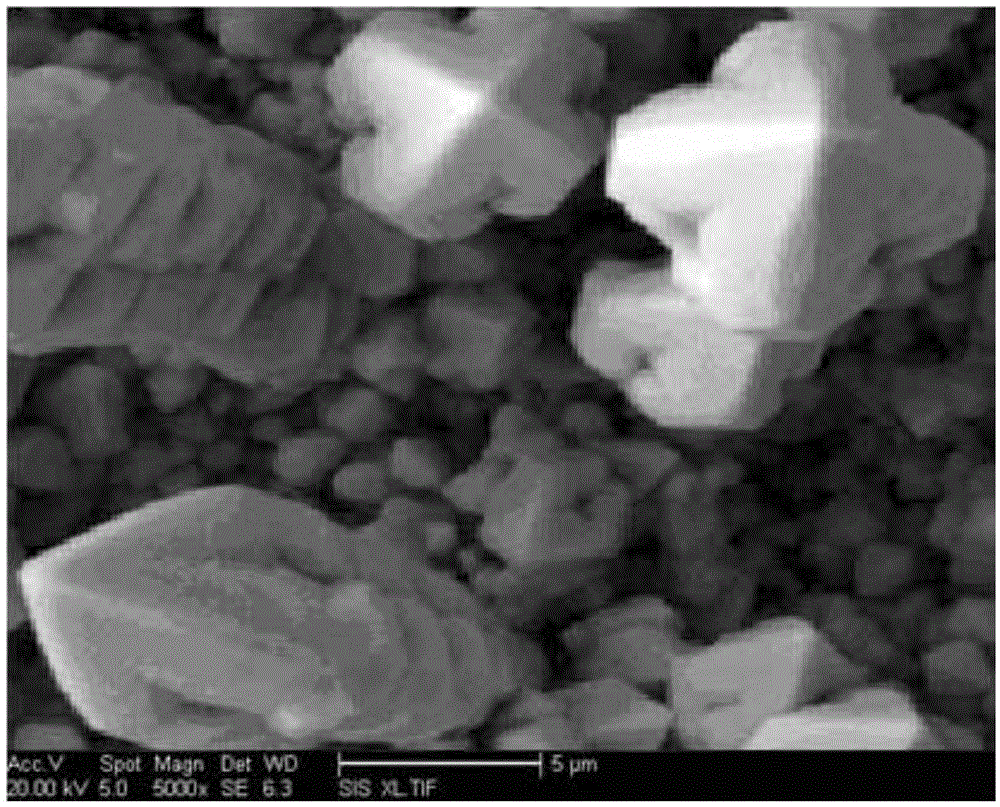

[0026] 2. Honeycombing on the surface of titanium plate:

[0027] The titanium mesh coated with ruthenium oxide is used as the anode, the pretreated titanium plate is used as the cathode, and then the titanium mesh anode coated with ruthenium oxide and the pretreated titanium plate cathode are placed in the honeycomb treatment solution at a temperature of 80 ° C ~90℃ and current density 5A / dm 2 ~20A / dm 2 Under the conditions of 10s ~ 20s, and then at a temperature of 80 ℃ ~ 90 ℃ and a current density of 0.5A / dm 2 ~2A / dm 2 Under certain conditions, treat for 10-30 minutes, take out the titanium plate aft...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that: the thickness of the titanium plate described in step 1 is 0.1 mm to 0.5 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the degreasing and pickling described in step 1 are carried out according to the following steps: immerse the titanium plate in a temperature range of 60° C. to 70° C. In the degreasing solution at ℃, the immersion time is 10min~30min to obtain the degreased titanium plate. At room temperature, immerse the degreased titanium plate in the pickling solution for 1min~2min to obtain the pretreated titanium plate;

[0037] The degreasing liquid is composed of sodium carbonate, sodium phosphate and sodium silicate; the concentration of sodium carbonate in the degreasing liquid is 35g / L~45g / L; the concentration of sodium phosphate in the degreasing liquid is 45g / L~55g / L; the concentration of sodium silicate in the degreasing liquid is 20g / L~30g / L;

[0038] The pickling liquid is composed of 42% hydrofluoric acid, 65% concentrated nitric acid and 30% hydrogen peroxide by mass percentage; 42% hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com