Acyl chloride monomer and preparation method thereof and reverse osmosis composite membrane and preparation method thereof

A monomer and acid chloride technology, applied in the field of reverse osmosis, can solve the problems of reducing membrane desalination rate, shortening membrane service life, and destroying desalination layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

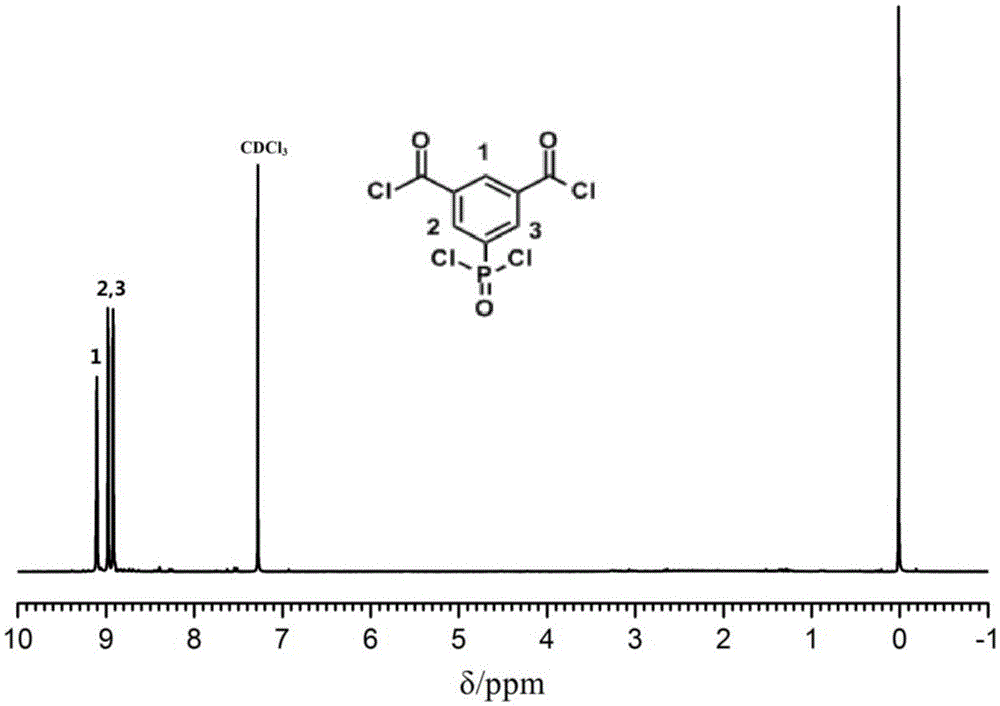

[0056] The invention provides a kind of preparation method of the acid chloride monomer with formula I structure, comprises the following steps:

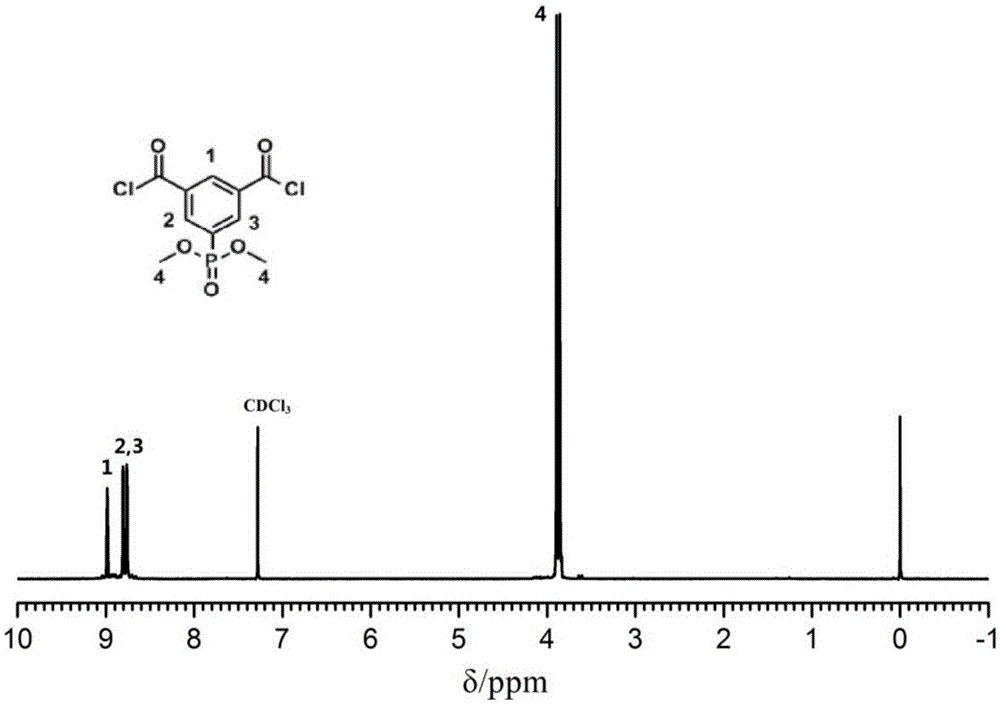

[0057] A1) Under the conditions of a protective atmosphere and a metal salt catalyst, the compound having the structure of formula II is mixed with a phosphorus source to react to obtain a compound having the structure of formula III; the source of phosphorus includes dimethyl phosphate, triphosphate One or more of methyl ester, dimethyl phosphite and trimethyl phosphite;

[0058]

[0059] Among them, R 1 `~R 5 `at least any two of -COOCH 3 , and the rest are selected from H;

[0060] A2) After mixing and reacting the compound having the structure of formula III obtained in the above steps with an alkaline solution, and then adjusting to acidic conditions, an intermediate compound is obtained;

[0061] A3) reacting the above-mentioned intermediate compound with an acylating agent to obtain an acid chloride monomer having a st...

Embodiment 1

[0124] Ordinary reverse osmosis composite membrane without new acid chloride monomer

[0125] 165g of polysulfone with a mass concentration of 16.5%, 135g of ethylene glycol monomethyl ether with a mass concentration of 13.5%, and 0.3g of sodium dodecylsulfonate with a mass concentration of 0.03% were dissolved in 699.7g of N,N-dimethyl In formamide, scrape on polyester non-woven fabric, immerse it in deionized water at room temperature for phase inversion, remove good solvent, obtain porous polysulfone support layer with molecular weight cut off (MWCO) of 20000-50000, and then store in in deionized water for later use.

[0126] Pour the mass volume concentration (g / mL) of 3% m-phenylenediamine aqueous solution onto the surface of the polysulfone support layer membrane, the solution covers the surface of the polysulfone support layer membrane for 1 minute, and pour off the excess m-phenylenediamine solution on the membrane surface , dry in the air for 3 minutes, and then the ...

Embodiment 2

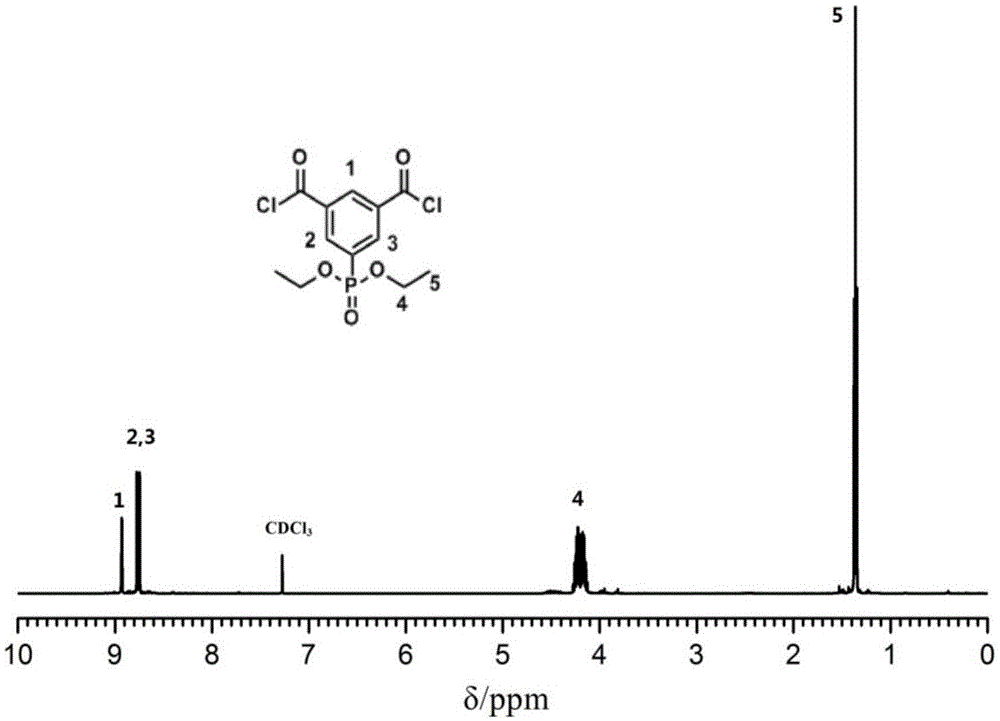

[0130] Using a mixture of trimesoyl chloride and monomer 1 (diethyl 3,5-dichloroformylphenylphosphonate), the mass volume concentration (g / mL) of the total aromatic polyacyl chlorides is 0.40%, and its weight ratio For trimesoyl chloride: monomer 1 (diethyl 3,5-dichloroformylphenylphosphonate) is 9:1. All the other conditions are with embodiment 1.

[0131] A performance test was performed on the reverse osmosis composite membrane prepared in Example 2 of the present invention, and the specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com