Composite desulfurization agent and preparation method thereof

A desulfurizer and composite technology, which is applied in the processing of gas mixtures, petroleum industry, and hydrocarbon oil treatment, etc., to reduce the probability of thermally stable salts, suppress foaming, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

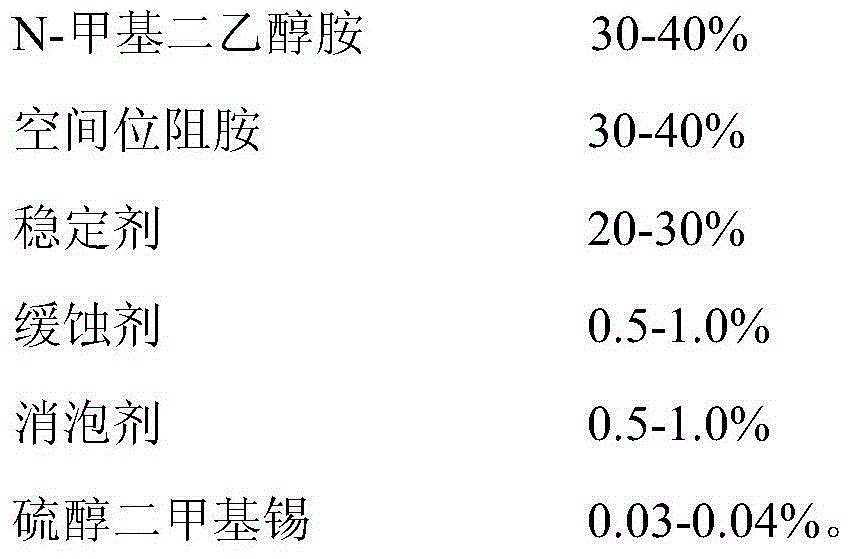

[0029] The raw material gross mass is 1 ton, and the raw material composition is as follows, by weight percentage:

[0030]

[0031]

[0032] N-methyldiethanolamine, tertiary aminopolypropylene glycol ether, and diethylethanolamine are mixed into a mixing tank according to the weight percentage and mixed and stirred for 20 minutes, and then ammonium molybdate, tertiary aminoorganosiloxane, and thiol dimethyl Tin, after using the circulation pump to circulate and return for 60 minutes, put it into the low-pressure desulfurization system with a pressure of 8KPAg, the cycle time is more than 5000 hours, and the sample is taken every eight hours. The sulfur content of the purified gas is measured to be below 5ppm, the carbon dioxide is not removed, and the energy consumption of the device is reduced. 37%, the composite desulfurizer has a good effect.

Embodiment 2

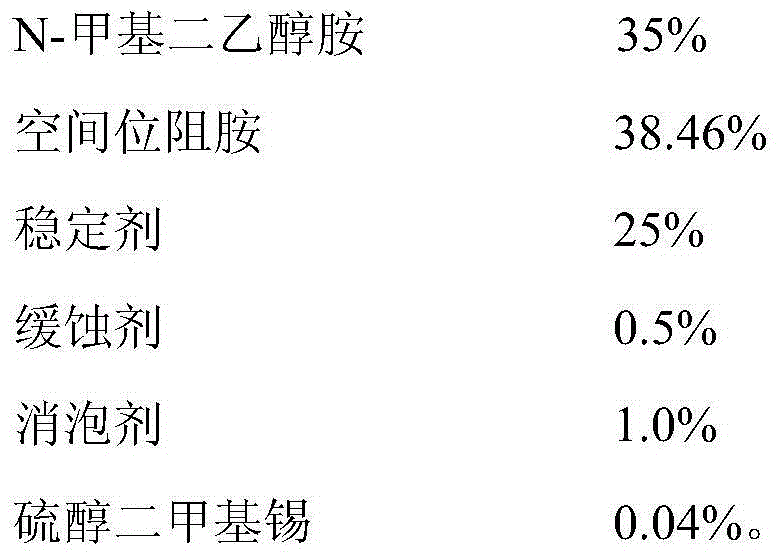

[0034] The raw material gross mass is 1 ton, and the raw material composition is as follows, by weight percentage:

[0035]

[0036] N-methyldiethanolamine, tertiary aminopolypropylene glycol ether, N-(2-hydroxybutyl)-1,2-propylenediamine are mixed into the mixing tank according to the weight percentage and mixed and stirred for 30min, and then ammonium tungstate, The tertiary amino organosiloxane and dimethyl tin mercaptide were circulated and refluxed for 40 minutes by a circulation pump, put into a low-pressure desulfurization system with a pressure of 7KPAg, and the cycle life was more than 5,500 hours. Samples were taken every eight hours, and the sulfur content of the purified gas was measured to be 5ppm Below, the carbon dioxide is not removed, and the energy consumption of the device is reduced by 35%. The use effect of this composite desulfurizer is good.

Embodiment 3

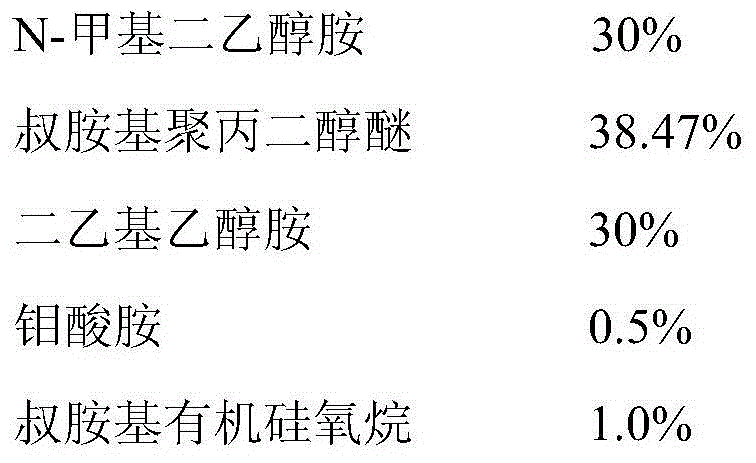

[0038] The raw material gross mass is 1 ton, and the raw material composition is as follows, by weight percentage:

[0039]

[0040] N-methyldiethanolamine, tertiary aminopolypropylene glycol ether, and 4-methylmorpholine were put into a mixing tank according to weight percentage and mixed and stirred for 30 minutes, then polyphosphate amine, tertiary aminoorganosiloxane, mercaptan Methyl tin, using a circulating pump to circulate back for 50 minutes, put into a low-pressure desulfurization system with a pressure of 10KPAg, the cycle life is more than 5,500 hours, and the sample is taken every eight hours. The sulfur content of the purified gas is measured to be below 5ppm, and the carbon dioxide is not removed. The energy consumption of the device 33% reduction, the composite desulfurizer works well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com