Enteromorpha prolifera oligosaccharide with auxiliary blood sugar decreasing function and preparation method thereof

A technology of enteromorpha oligosaccharides and hypoglycemia, which is applied in the field of medicine to achieve the effects of convenient operation, reduced enzyme dosage and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

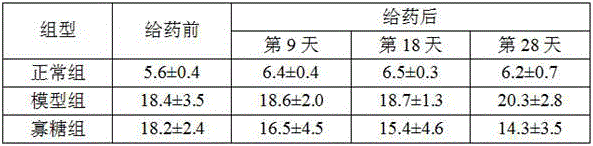

Image

Examples

Embodiment 1

[0022] (1) Dried and crushed Enteromorpha, added 60% ethanol to the dry powder of Enteromorpha and refluxed for extraction for 1 hour, the ratio of dry powder weight to ethanol volume (g / mL) was 1:20, recovered and removed the ethanol for recycling after reflux, and dried Dry to obtain dry defatted Enteromorpha powder;

[0023] (2) Add distilled water to the degreased Enteromorpha powder prepared in step (1), wherein the mass ratio of Enteromorpha to distilled water volume (g / mL) is 1:25, 480W microwave-assisted extraction at an extraction temperature of 60-70°C for 2 minutes, After the extraction is completed, filter, repeat the above steps for 2 extractions of the filter residue, mix the obtained filtrate and concentrate, add 3 times the volume of 95% ethanol, settling at 4°C for 8 hours, collect the precipitate by centrifugation, and vacuum freeze-dry After crushing, the crude Enteromorpha sulfated polysaccharide is obtained.

[0024] (3) Add distilled water to the crude s...

Embodiment 2

[0036] (1) Dried and crushed Enteromorpha, added 80% ethanol to the dry powder of Enteromorpha and refluxed for 2 hours, the ratio of dry powder weight to ethanol volume (g / mL) was 1:30, recovered and removed ethanol for recycling after reflux, and dried Dry to obtain dry defatted Enteromorpha powder;

[0037] (2) Add distilled water to the degreased Enteromorpha powder prepared in step (1), wherein the mass ratio of Enteromorpha to distilled water volume (g / mL) is 1:30, 600W microwave-assisted extraction at an extraction temperature of 70°C for 3 minutes, and the extraction is complete Afterwards, filter, repeat the above steps for 3 extractions of the filter residue, mix the obtained filtrate and concentrate, add 4 times the volume of 95% ethanol, let it settle at 10°C for 12 hours, collect the precipitate by centrifugation, vacuum freeze-dry and crush , to get crude Enteromorpha sulfated polysaccharide.

[0038] (3) Add distilled water to the crude sulfated polysaccharide ...

Embodiment 3

[0050] (1) Dried Enteromorpha and pulverized it, added 50% ethanol to the dry powder of Enteromorpha and refluxed it for 1.5 hours. The ratio of dry powder weight to ethanol volume (g / mL) was 1:25. Dry to obtain dry defatted Enteromorpha powder;

[0051] (2) Add distilled water to the defatted Enteromorpha powder prepared in step (1), wherein the mass ratio of Enteromorpha to distilled water volume (g / mL) is 1:28, 520W microwave-assisted extraction at an extraction temperature of 65°C for 2 minutes, and the extraction is complete Afterwards, filter, repeat the above steps to extract the filter residue twice, mix the obtained filtrate and concentrate, add 4 times the volume of 95% ethanol, settling at 8°C for 10 hours, centrifuge to collect the precipitate, vacuum freeze-dry and crush , to get crude Enteromorpha sulfated polysaccharide.

[0052] (3) Add distilled water to the crude sulfated polysaccharide of Enteromorpha enteromorpha obtained in step (2), wherein the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com