Preparation method of bismuth-layered compound superlattice

A superlattice and compound technology, applied in the manufacture/processing of thermoelectric devices, electrical components, circuits, etc., can solve the problems of high cost, opacity, and unfavorable expansion research and application of superlattice devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

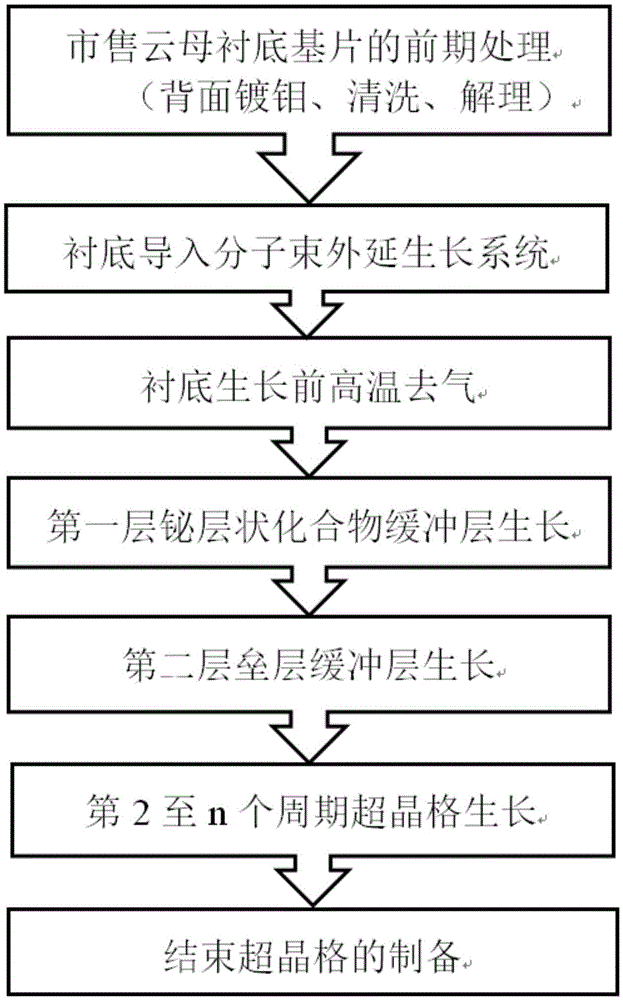

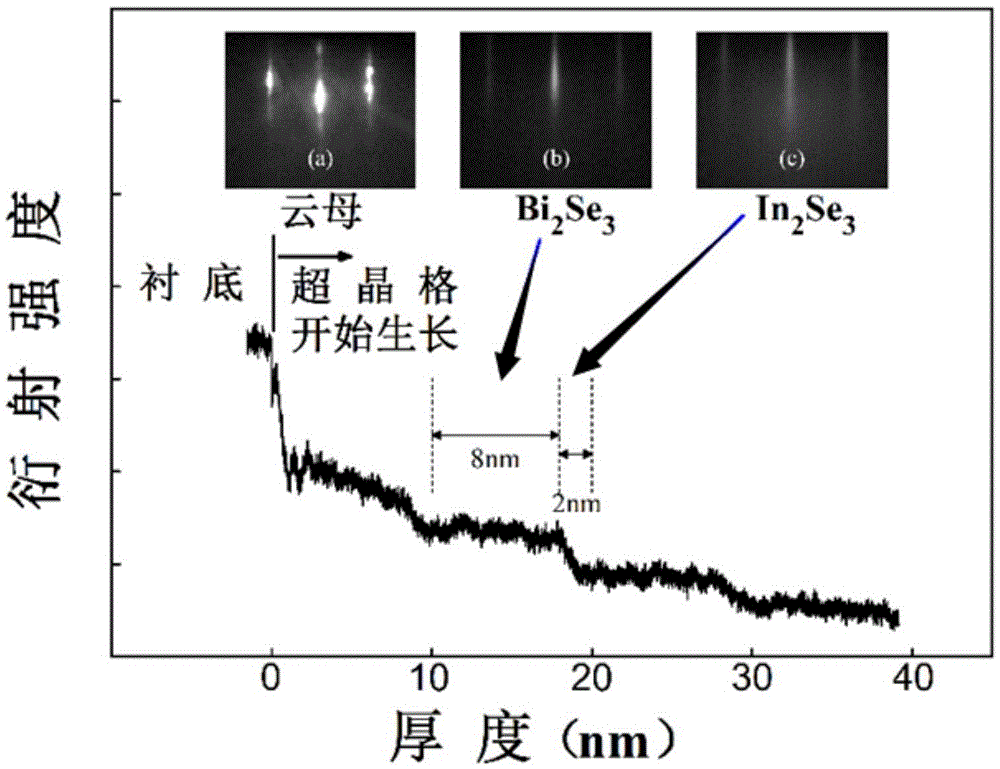

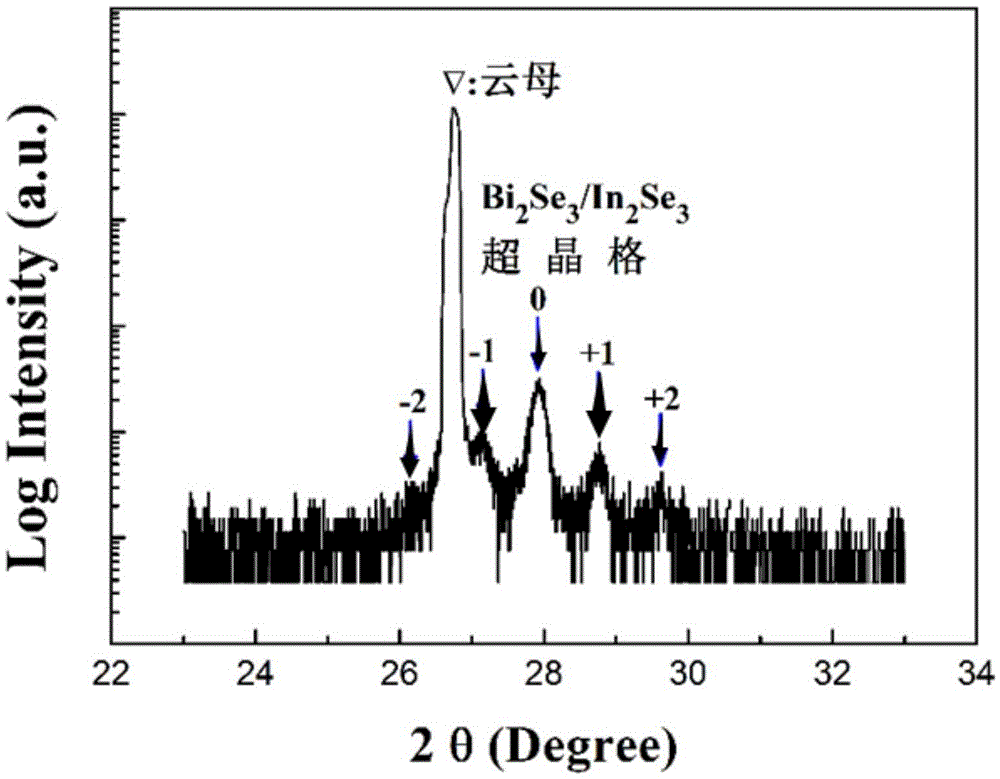

[0020] Embodiment 1: The periodic structure prepared on the muscovite substrate is Bi 2 Se 3 / In 2 Se 3 (8nm / 2nm) superlattice method is:

[0021]Step (1)——Using magnetron sputtering or electron beam evaporation to carry out molybdenum plating on the back of the muscovite sheet substrate; immerse the molybdenum-plated substrate in acetone and absolute ethanol solution in turn for ultrasonic cleaning, and The solution was washed for 3 minutes, and the cleaning was repeated 2 to 3 times; the surface of the muscovite was blown clean with high-purity nitrogen, and then the front side of the muscovite substrate was stuck on the tape, and then the tweezers were used to clamp the muscovite substrate along the direction perpendicular to the muscovite. The surface direction is quickly and evenly torn off to obtain the muscovite substrate;

[0022] Step (2)—Introduce the muscovite substrate into the molecular beam epitaxy system, heat it to 350-450°C to degas it, until the backgroun...

Embodiment 2

[0029] Example 2: The periodic structure prepared on the fluorine phlogopite substrate is Bi 2 Se 3 / In 2 Se 3 (8nm / 2nm) superlattice method is:

[0030] Step (1)—Using magnetron sputtering or electron beam evaporation to carry out molybdenum plating on the back of the fluorphlogopite sheet substrate; soak the molybdenum-plated substrate in acetone and absolute ethanol solutions for ultrasonic cleaning, and Wash in each solution for 3 minutes, and wash repeatedly 2 to 3 times; blow off the surface of fluorphlogopite with high-purity nitrogen, then stick the front side of the fluorphlogopite substrate on the tape, and then use tweezers to clamp the fluorphlogopite substrate along the Quickly and evenly tear it off perpendicular to the surface of fluorphlogopite to obtain a fluorphlogopite substrate;

[0031] Step (2)—Introduce the fluorine phlogopite substrate into the molecular beam epitaxy system, and heat it to 350-450°C to degas it until the background vacuum reaches 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com