Water-repellent anti-UV textile, production method and application thereof

A production method and textile technology, applied in the field of materials and textiles, can solve the problems of unresolved washing durability of textiles, and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

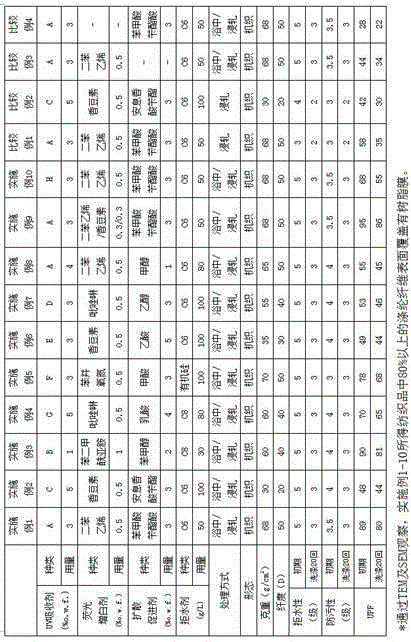

Embodiment 1

[0064] Prepared weight 68g / m 2 Thin polyester woven fabric (both warp and weft yarns are 50D-48f-DTY), put it into UV absorber A3% o.w.f., stilbene type fluorescent whitening agent 0.5% o.w.f. and diffusion accelerator 3% benzyl benzoate o.w.f. In the treatment solution formed (bath ratio 1:20), the temperature was raised to 90°C for 60 minutes of bath finishing, and then reduction cleaning was performed according to the conventional method (30% NaOH solution 2g / L, hydrosulfite 2g / L, 80℃×20 minutes), and finally 130℃×2 minutes for drying;

[0065] Then use 50g / L of water-repellent agent (C6 fluorine series), 10g / L of bridging agent isocyanate, and 10g / L of penetrating agent isopropanol to perform one-dipping and one-rolling water-repellent processing. Dry for 2 minutes and heat-set at 170° C. for 1 minute to obtain the polyester textile of the present invention. Its properties are detailed in Table 1.

Embodiment 2

[0067] Prepare gram weight 30g / m 2 Thin polyester woven fabric (both warp and weft yarns are 20D-36f-DTY), put it into UV absorber C5%o.w.f., diffusion accelerator benzyl benzoate 2%o.w.f., coumarin type fluorescent whitening agent 0.5%o.w.f. Mix evenly, bath ratio: 1:20; heat up to 100°C for 40 minutes in the bath, and then perform reduction cleaning according to the conventional method (30% NaOH solution 2g / L, hydrosulfite 2g / L, 80°C×20 minutes ), and finally dry at 130°C for 2 minutes.

[0068] Then use 100g / L of water-repellent agent (C6 fluorine series), 15g / L of bridge-linking agent polyurethane, and 5g / L of penetrating agent fatty alcohol polyoxyethylene ether to carry out one-dipping and one-rolling water-repellent processing, and the rolling rate is 60%. Dry at 120°C for 2 minutes and heat set at 160°C for 2 minutes to obtain the polyester textile of the present invention. Its properties are detailed in Table 1.

Embodiment 3

[0070] Prepared weight 60g / m 2 Thin polyester woven fabric (both warp and weft yarns are 40D-48f-DTY), put it into UV absorber B1% o.w.f., diffusion accelerator 2% o.w.f. benzyl alcohol, phthalimide type fluorescent whitening agent 1% o.w.f. Mix evenly, bath ratio: 1:30; heat up to 110°C for 30 minutes in the bath, and then perform reduction cleaning according to the conventional method (30% NaOH solution 2g / L, hydrosulfite 2g / L, 80°C×20 minutes), and finally dry at 130°C for 2 minutes.

[0071] Then use 30g / L of water repellent agent (C8 fluorine series), 20g / L of bridging agent isocyanate, and 8g / L of penetrating agent isopropanol to perform one-dipping and one-rolling water-repellent processing. Dry for 3 minutes and heat-set at 180° C. for 1 minute to obtain the polyester textile of the present invention. Its properties are detailed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com