A preparation method of nickel hydroxide/graphene composite material for positive electrode of nickel-hydrogen battery

A nickel-metal hydride battery and battery positive electrode technology, applied in the field of nickel-hydrogen battery electrode materials, can solve the problems of reduced battery life and reduced activity of electrode active materials, and achieve the effects of short crystallization time, improved electrochemical utilization, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 100 mg GO and ultrasonically disperse it into 100 mL deionized water to obtain a 1 mg / mL brown suspension. Weigh 1.568g Ni(NO 3 ) 2 ·6H 2 O was added to the GO suspension and stirred for 2 h to complete the ion exchange. Then, 20 mL of 1.62 mol / L aqueous urea solution was added dropwise to the suspension, and stirring was continued for 1 h. The reaction mixture (GO:Ni(OH) 2 =1:5(wt.)) into a 500ml three-neck flask, put the flask in an Apex atmospheric pressure microwave reaction synthesizer, heat up to 100°C under a microwave power of 800W, react at a constant temperature for 3 hours, then cool naturally to room temperature, and then vacuumize filtered, and washed repeatedly with deionized water and absolute ethanol until neutral, and vacuum-dried at 80°C for 12h to obtain Ni(OH) 2 / graphene composites.

Embodiment 2

[0019] Weigh 100 mg GO and ultrasonically disperse it into 100 mL deionized water to obtain a 1 mg / mL brown suspension. Weigh 2.823g Ni(NO 3 ) 2 ·6H 2 O was added to the GO suspension and stirred for 2 h to complete the ion exchange. Then, 20 mL of 2.91 mol / L aqueous urea solution was added dropwise to the suspension, and stirring was continued for 1 h. The reaction mixture (GO:Ni(OH) 2 =1:9(wt.)) into a 500ml three-neck flask, put the flask in an Apex atmospheric pressure microwave reaction synthesizer, heat up to 100°C under a microwave power of 800W, react at a constant temperature for 3 hours, cool naturally to room temperature, and carry out vacuum pumping filtered, and washed repeatedly with deionized water and absolute ethanol until neutral, and vacuum-dried at 80°C for 12h to obtain Ni(OH) 2 / graphene composites.

[0020] The load ratio is GO:Ni(OH) 2 =1:13(wt.) The principle of the preparation method is the same as above.

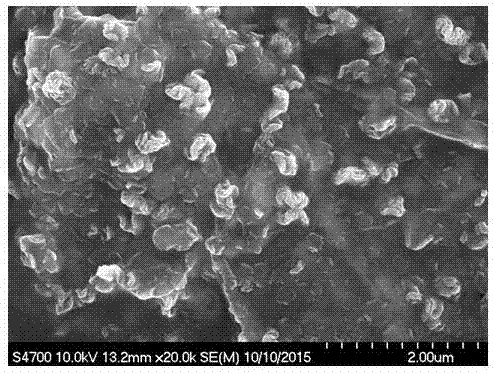

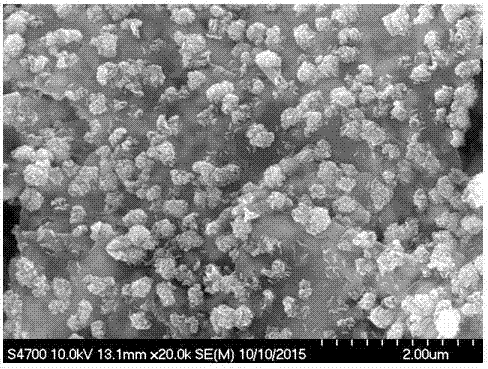

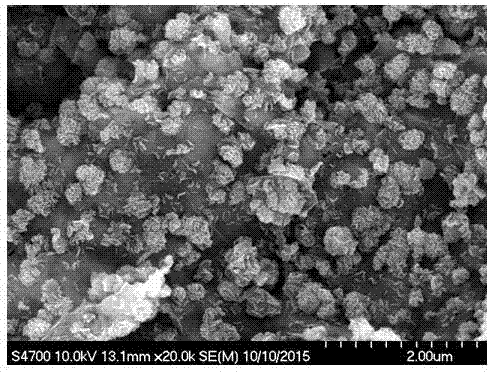

[0021] figure 1 , figure 2 , i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com