A conductive polymer/snse for sodium-ion batteries x Nanoflower negative electrode composite material and preparation method thereof

A conductive polymer and sodium ion battery technology, applied in battery electrodes, batteries, negative electrodes, etc., can solve the problem of no composite material sodium battery negative electrode materials, etc., to improve electrochemical utilization, promote contact, and high charge-discharge ratio The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

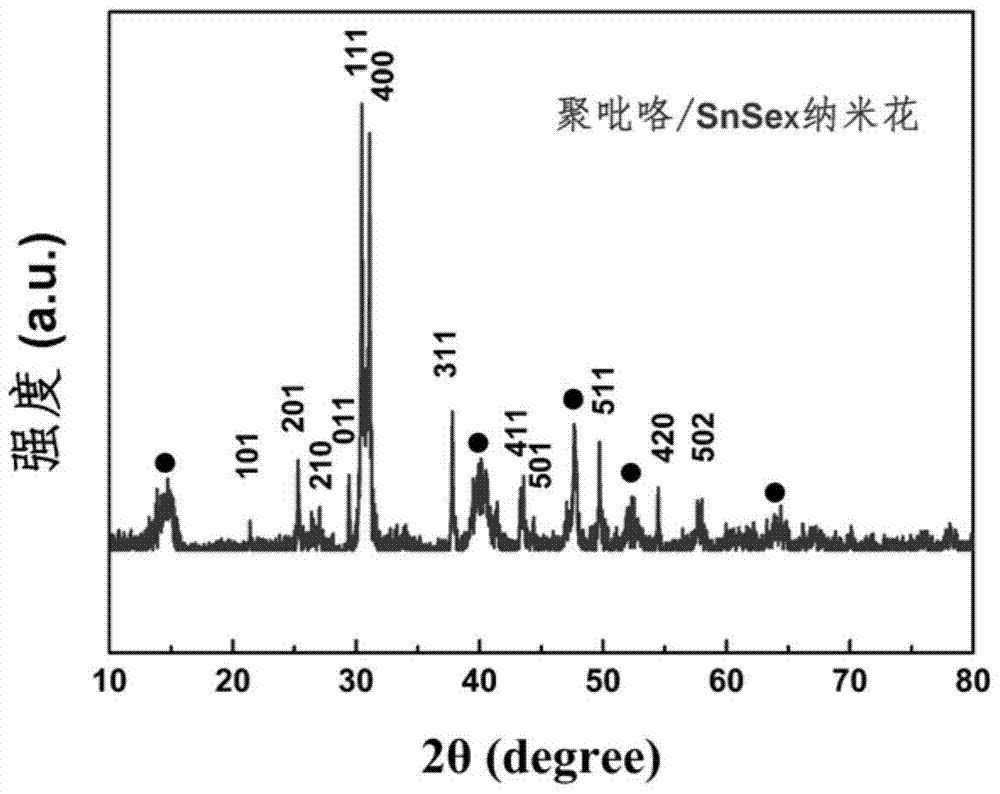

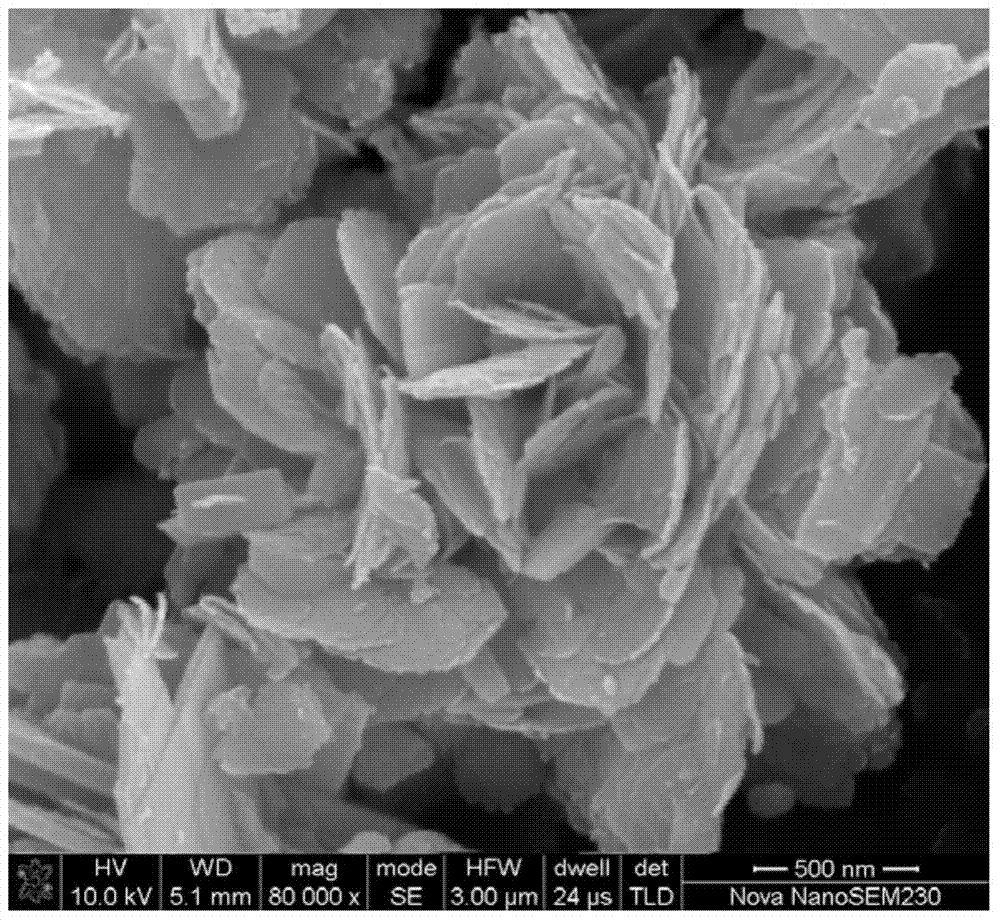

[0038] First weigh 0.175g of tin tetrachloride pentahydrate, 0.055g of selenium oxide and 0.035g of o-phenanthroline into 40ml of oleylamine, stir in an oil bath at 70°C for 2h to obtain a transparent and clear solution, and then transfer the solution to high pressure In the reaction kettle, solvothermal reaction was carried out at 180 ° C for 24 h, after cooling, centrifuged and dried to obtain SnSe x nanoflowers.

[0039] Weigh 0.2g SnSe x Add nanoflowers and 0.02g cetyltrimethylammonium bromide into deionized water and sonicate for 5h, then add 0.4ml pyrrole monomer in an ice bath at 0°C and continue stirring for 2h, then slowly add 57ml dropwise to a concentration of 0.1mol / L of ammonium persulfate solution, under continuous stirring conditions, the polymerization reaction takes place for 3 hours, and the polypyrrole / SnSe x Nanoflower anode composite material.

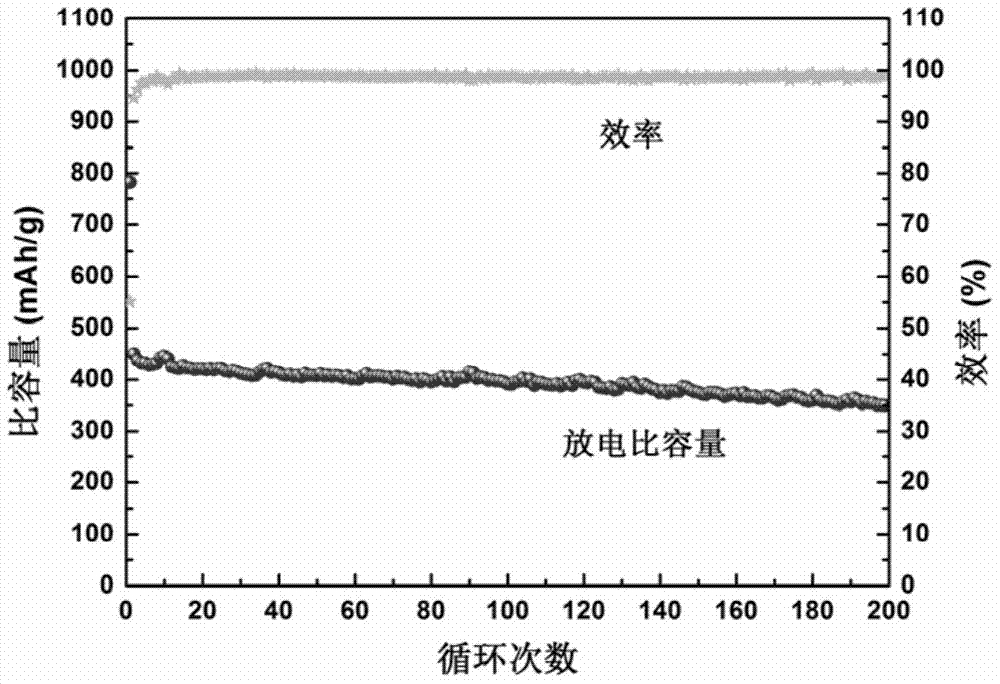

[0040] The sodium battery composite negative electrode material prepared in this example and the sodium shee...

Embodiment 2

[0046] First weigh 0.175g of tin tetrachloride pentahydrate, 0.055g of selenium oxide and 0.018g of o-phenanthroline into 40ml of oleylamine, stir in an oil bath at 70°C for 2h to obtain a transparent and clear solution, and then transfer the solution to a high pressure In the reaction kettle, solvothermal reaction was carried out at 180 ° C for 24 h, after cooling, centrifuged and dried to obtain SnSe x nanoflowers.

[0047] Weigh 0.2g SnSe x Add nanoflowers and 0.02g cetyltrimethylammonium bromide into deionized water and sonicate for 3h, then add 0.4ml pyrrole monomer in an ice bath at 0°C and continue stirring for 1h, then slowly add 57ml dropwise to a concentration of 0.1mol / L ammonium persulfate solution, under continuous stirring conditions, the polymerization reaction takes place for 3 hours, and the polypyrrole / SnSex nanoflower negative electrode composite material can be obtained.

[0048] The tin phosphide / graphene negative electrode composite material prepared i...

Embodiment 3

[0050] First weigh 0.175g of tin tetrachloride pentahydrate, 0.055g of selenium oxide and 0.035g of o-phenanthroline into 40ml of oleylamine, stir in an oil bath at 75°C for 2h to obtain a transparent and clear solution, and then transfer the solution to high pressure In the reaction kettle, solvothermal reaction was carried out at 180 ° C for 24 h, after cooling, centrifuged and dried to obtain SnSe x nanoflowers.

[0051] Weigh 0.2g SnSe x Add nanoflowers and 0.02g of cetyltrimethylammonium bromide into deionized water and sonicate for 5h, then add 0.8ml of pyrrole monomer in an ice bath at 0°C and continue stirring for 2h, then slowly add 114ml dropwise to a concentration of 0.1mol / L ammonium persulfate solution, under continuous stirring conditions, the polymerization reaction takes place for 6 hours, and the polypyrrole / SnSe x Nanoflower anode composite material.

[0052] The tin phosphide / graphene negative electrode composite material prepared in this example and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com