Hollow composite microspheres for positive electrode materials of lithium-sulfur batteries and preparation method thereof

A technology of composite microspheres and positive electrode materials, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of lithium-sulfur battery performance degradation, affecting electrochemical performance, poor conductivity of elemental sulfur, etc., to improve the conductivity and structural stability, improving electrochemical utilization, and increasing the strength of hollow structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

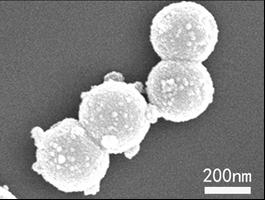

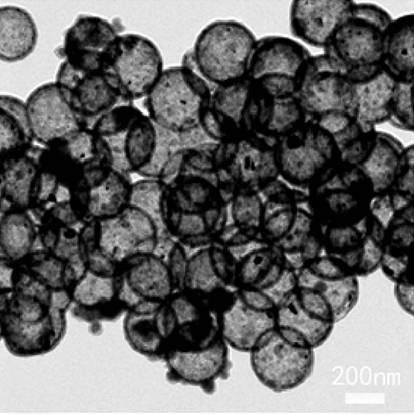

[0027] 1) Preparation of polystyrene template microspheres: Measure 11mL St and 5mL AA, add them dropwise to 70mL deionized water, stir for 30 minutes under high-purity nitrogen gas, heat to 70°C, then add 10mL deionized water containing 0.1gKPS Ion aqueous solution was used as an initiator, and PS microspheres with a diameter of about 250nm could be obtained by stirring at 70°C for 12h.

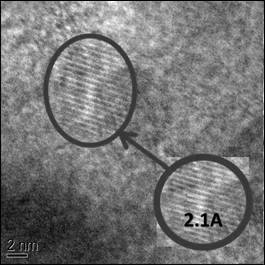

[0028] 2) PS / TiO 2 Preparation of composite microspheres: Take 0.5 g of PS microspheres prepared in step 1) and ultrasonically disperse them in 100 mL of ethanol, add 1 mL of TBOT and stir on a magnetic stirrer for 8 h, then add 50 mL of deionized water, mix and stir for 3 h to hydrolyze TBOT and self-assembled on the surface of microspheres to obtain PS / TiO 2 Composite microspheres.

[0029] 3) PS / TiO 2 / PDA composite microspheres: take 0.5 g of PS / TiO prepared in step 2) 2 The composite microspheres were ultrasonically dispersed in 400mL of a mixed solvent with a volume ratio of ethano...

Embodiment 2

[0034] 1) Preparation of polystyrene template microspheres: according to Example 1.

[0035] 2) PS / TiO 2 Preparation of composite microspheres: Take 0.5 g of PS microspheres prepared in step 1) and ultrasonically disperse them in 100 mL of ethanol, add 0.5 mL of TBOT and stir on a magnetic stirrer for 8 h, then add 50 mL of deionized water, and mix and stir for 3 h to make TBOT Hydrolyzed and self-assembled on the surface of microspheres to obtain PS / TiO 2 Composite microspheres.

[0036] 3) PS / TiO 2 Preparation of / PDA composite microspheres: Carry out according to Example 1.

[0037] 4) PS / TiO 2 / C / MnO 2 Preparation of composite microspheres: take 0.5 g of PS / TiO prepared in step 3) 2 / PDA composite microspheres dispersed in 250mL KMnO with a concentration of 5mM 4 Stir in the aqueous solution for 10min and centrifuge to obtain PS / TiO 2 / C / MnO 2 Composite microspheres.

[0038] 5) TiO 2 / C / MnO 2 Preparation of composite microspheres: according to Example 1.

[0...

Embodiment 3

[0041] 1) Preparation of polystyrene template microspheres: according to Example 1.

[0042] 2) PS / TiO 2 Preparation of composite microspheres: Take 0.5 g of PS microspheres prepared in step 1) and ultrasonically disperse them in 100 mL of ethanol, add 1.5 mL of TBOT and stir on a magnetic stirrer for 8 h, then add 50 mL of deionized water, and mix and stir for 3 h to make TBOT Hydrolyzed and self-assembled on the surface of microspheres to obtain PS / TiO 2 Composite microspheres.

[0043] 3) PS / TiO 2 Preparation of / PDA composite microspheres: Carry out according to Example 1.

[0044] 4) PS / TiO 2 / C / MnO 2 Preparation of composite microspheres: take 0.5 g of PS / TiO prepared in step 3) 2 / PDA composite microspheres dispersed in 250mL KMnO with a concentration of 15mM 4 Stir in the aqueous solution for 10min and centrifuge to obtain PS / TiO 2 / C / MnO 2 Composite Microspheres

[0045] 5) TiO 2 / C / MnO 2 Preparation of composite microspheres: according to Example 1.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com